Ribbon mechanism for concave code printing

A ribbon mechanism and ribbon technology, applied in printing, inking devices, etc., can solve the problems of undetectable ribbon feed length, complex structure, etc., avoid scratching and winding of ribbon and characters, small size, and save consumables Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

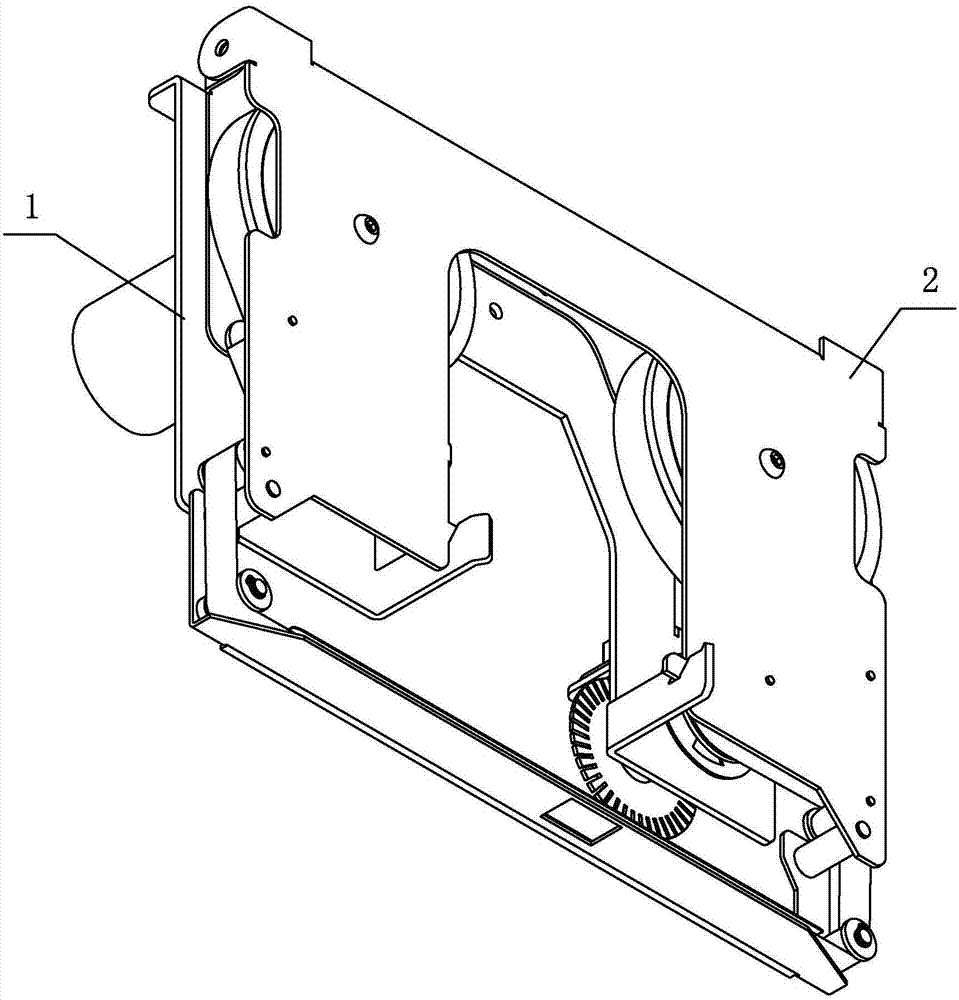

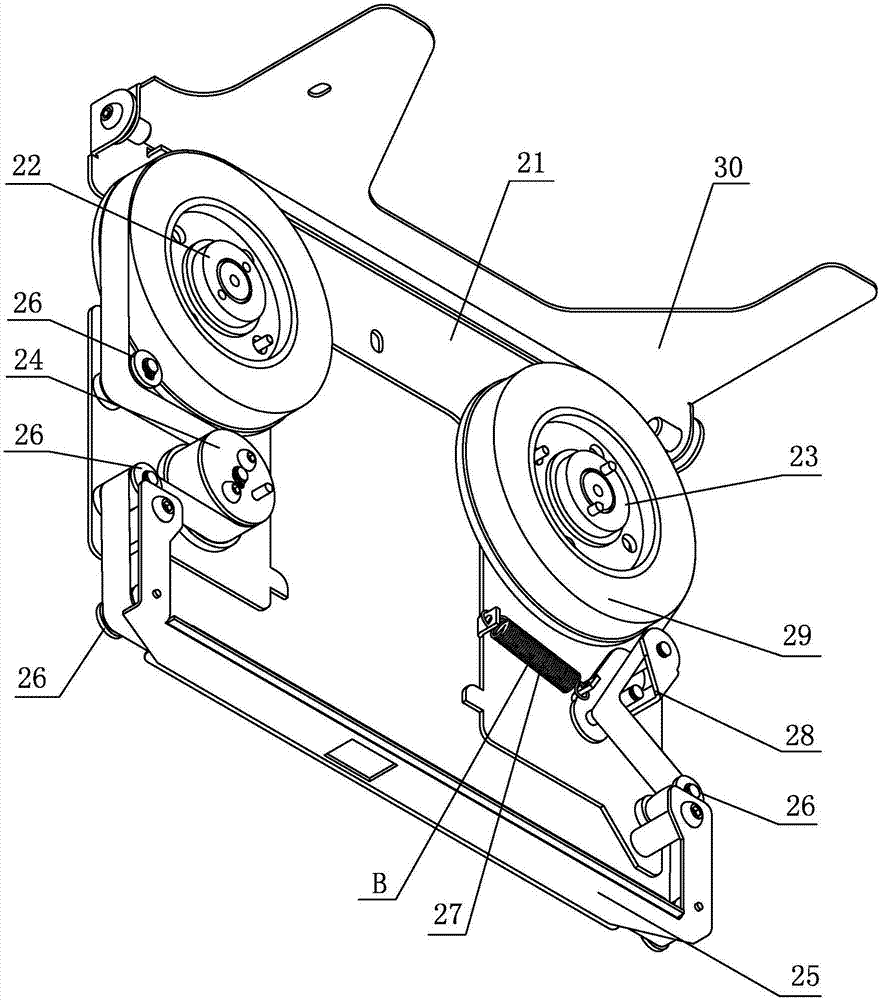

[0027] Such as Figure 1-Figure 3 As shown, a ribbon mechanism for concave code printing includes a ribbon 29, the ribbon 29 is a concave code printing ribbon with a transparent section at the end, it also includes a base part 1 and a ribbon box part 2;

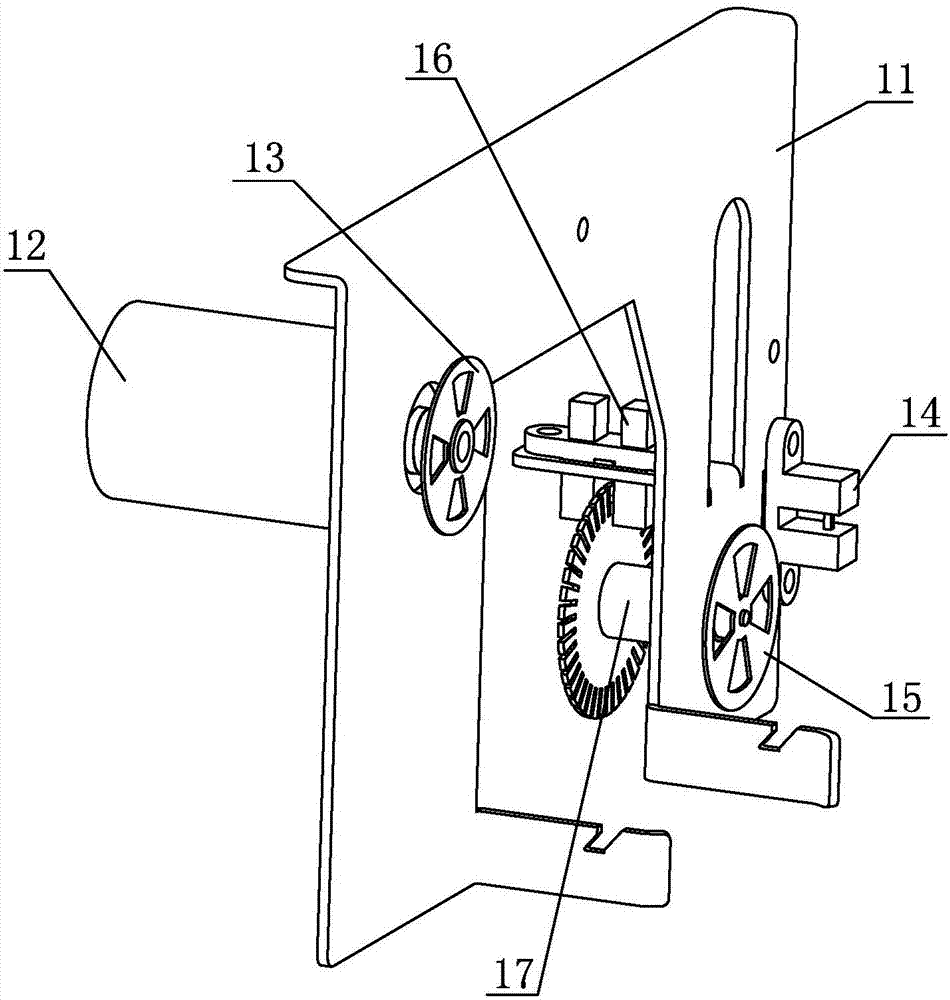

[0028] The base part 1 includes a mounting plate 11, a ribbon rolling motor 12, an exhaustion sensor 14, a feed sensor 16, and a feed detection connecting shaft 17; the ribbon cassette part 2 includes a bottom plate 21 and a ribbon supply seat 22 , Ribbon recovery seat 23, feed detection driven wheel 24, ribbon guard 25 and ribbon tightness adjuster B;

[0029] The ribbon rolling motor 12 is mounted on the mounting plate 11, the feed detection connecting shaft 17 is rotatably mounted on the mounting plate 11, and one end of the feed detection conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com