Micro motor shaft

A micro-motor and rotating shaft technology, applied in shafts, couplings, shafts and bearings, etc., can solve problems such as inability to continue working, and achieve the effects of increasing life, improving safety, and avoiding breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

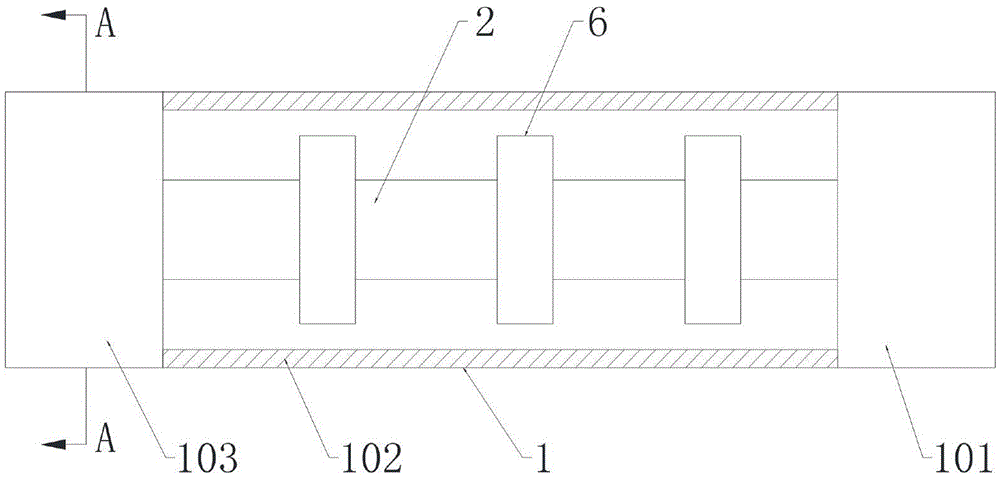

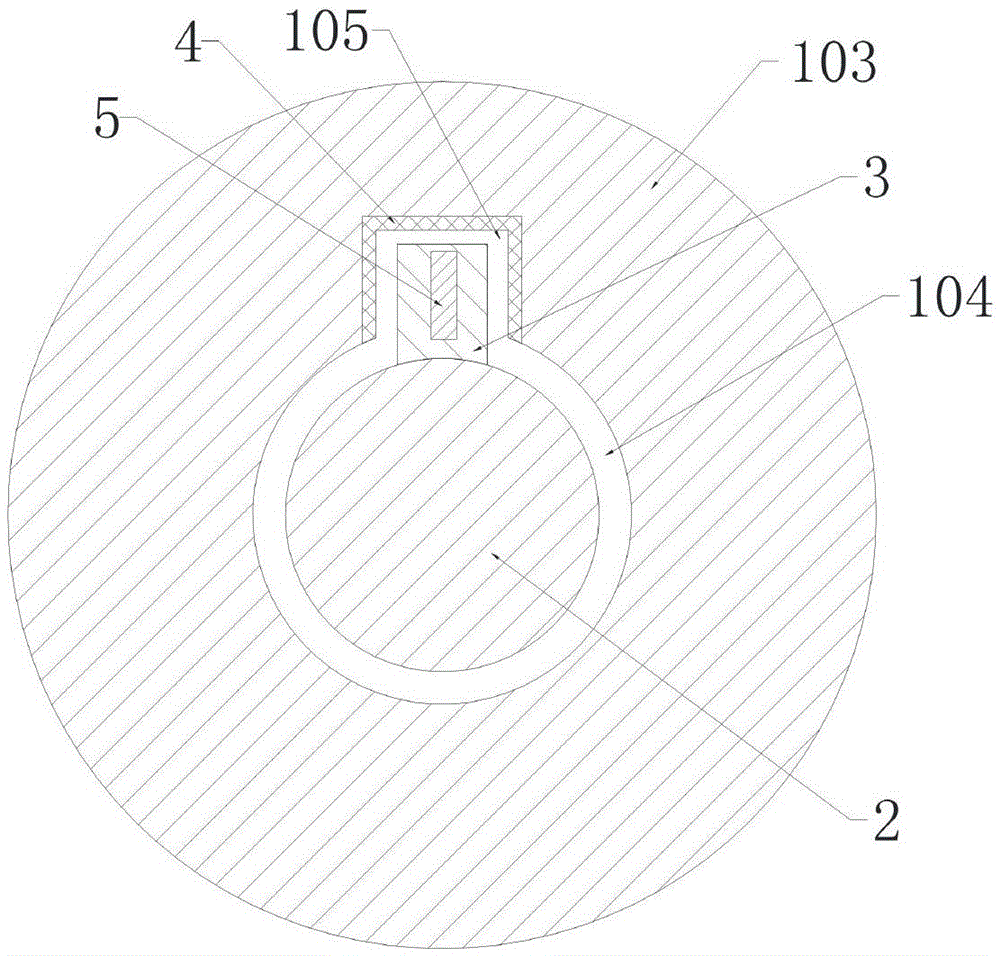

[0021] like figure 1 and figure 2 As shown, the rotating shaft of the micro-motor includes a rotating shaft 1 and an inner shaft 2; the rotating shaft body 1 includes an input section 101, a connecting cylinder 102 and a transmission section 103, and the two ends of the connecting cylinder 102 are respectively connected with the input section 101 and the transmission section 103, and the transmission section 103 is provided with a circular accommodation hole 104 and a square transmission hole 105 at one end close to the connecting cylinder 102, the square transmission hole 105 communicates with the circular accommodation hole 104; the inner shaft 2 is located in the connecting cylinder 102, and the inner shaft 2 includes a first end and the second end, the first end of the inner shaft 2 is connected with the input section 101, the second end of the inner shaft 2 is located in the circular accommodation hole 104, and the outer surface of the second end of the inner shaft 2 is ...

Embodiment 2

[0024] like figure 1 and figure 2 As shown, on the basis of Embodiment 1, this embodiment further includes a rubber layer 4 disposed on the inner wall of the square transmission hole 105 .

[0025] The rubber layer 4 is provided to act as a buffer when the transmission block 3 collides with the inner wall of the square transmission hole 105, so as to prevent the transmission block 3 from breaking and improve the reliability of the rotating shaft.

Embodiment 3

[0027] like figure 1 and figure 2 As shown, on the basis of Embodiment 1, this embodiment further includes a magnet block 5 arranged in the transmission block 3 .

[0028] The magnet block 5 is set so that the transmission block 3 and the inner wall of the square transmission hole 105 are bonded together after the connecting cylinder 103 is broken, so that the transmission block 3 and the inner wall of the square transmission hole 105 are prevented from colliding again when the rotating speed is changed, and the life of the rotating shaft is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com