Temperature sensing reversing valve

A reversing valve and inductive technology, applied in the field of temperature-sensing reversing valves, can solve the problems of weak adaptability to the use environment, high manufacturing cost, inconvenient installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

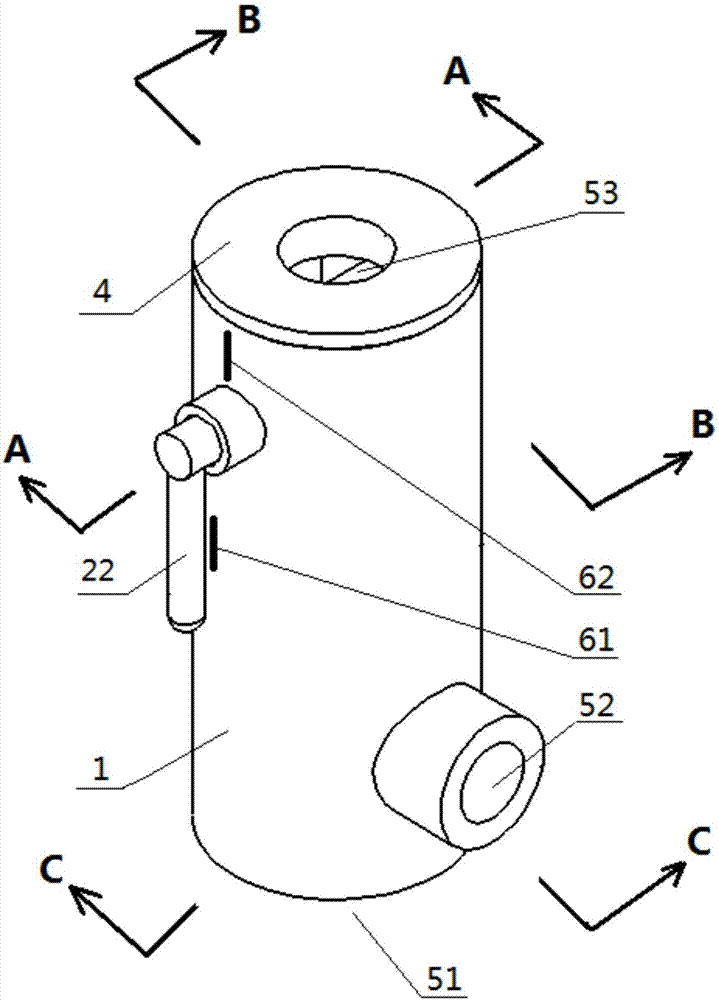

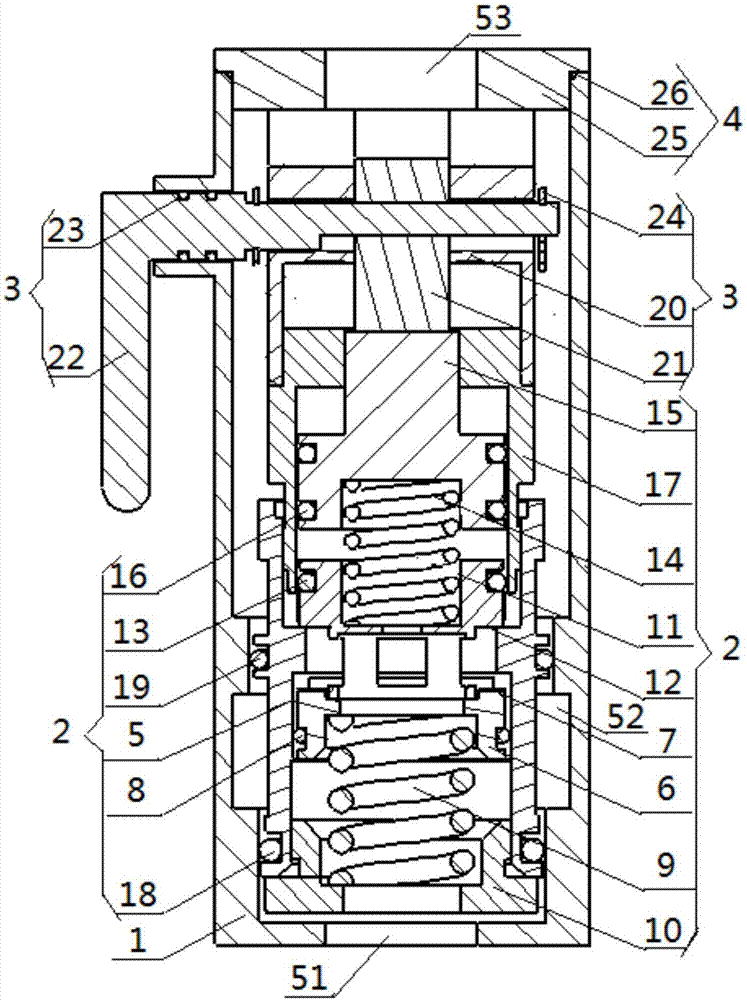

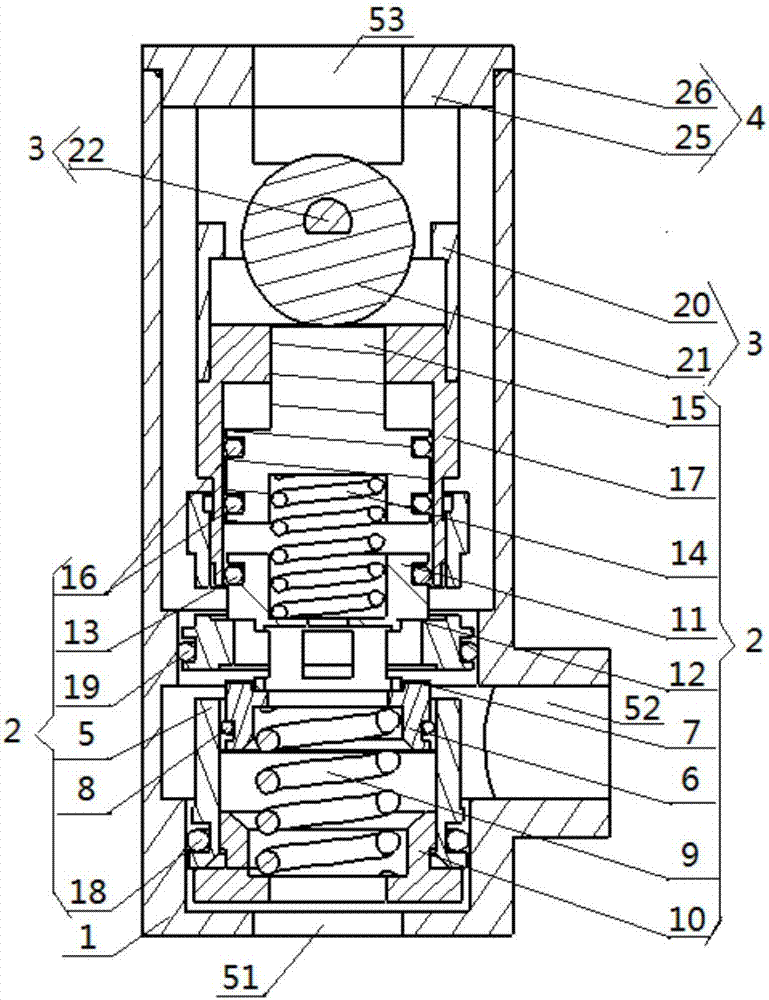

[0040] see Figure 1 to Figure 7 , this embodiment provides a temperature-sensing reversing valve, including a valve body 1 , a temperature-sensing reversing valve core 2 , a temperature-sensing switching assembly 3 and a valve body blocking assembly 4 . Among them, the valve body 1 is provided with a medium inlet channel 51, a low temperature medium outlet channel 52 and a high temperature medium outlet channel 53; one end of the medium inlet channel 51, the low temperature medium outlet channel 52 and the high temperature medium outlet channel 53 is inside the valve body Communication setting; the temperature-sensitive reversing spool 2 is set at the position where the three passages (medium inlet passage 51, low-temperature medium outlet passage 52 and high-temperature medium outlet passage 53) in the valve body 1 communicate with each other, and are used for the low-temperature medium outlet passage 52 switch between the medium flow channel and the high-temperature medium ...

Embodiment 2

[0048] The difference between the temperature-sensing reversing valve provided in this embodiment and the embodiment 1 lies in that the structure of the temperature-sensing reversing valve core is different. Other than that, other structures are the same as those in Embodiment 1, and will not be repeated in this embodiment.

[0049] see Figure 8 to Figure 10The temperature-sensitive reversing spool 2 of this embodiment includes a spool body 56, a spool c86, a sealing ring 8 for the spool a, a memory alloy spring 9, a blocking cover a10, a sealing ring 13 for the spool b, a spring b14, and a control cover 15. Control cover seal ring 16, plug cover b17, valve core body seal ring a18 and valve core body seal ring b19. Among them, the main body 56 of the spool is a tubular structure with a protruding step inside it, and the two sides of the step are respectively provided with a low-temperature medium outlet and a high-temperature medium outlet, and the inner cylindrical surface ...

Embodiment 3

[0054] The difference between the temperature-sensing reversing valve provided in this embodiment and the embodiment 1 is that it does not include a temperature-sensing switching component, the valve body is replaced by a small valve body, and the composition and structure of the temperature-sensing reversing valve core is different. Other than that, other structures are the same as those in Embodiment 1, and will not be repeated in this embodiment.

[0055] see Figure 11 and Figure 12 , the temperature-sensing reversing valve of this embodiment includes a small valve body 66 , a temperature-sensing reversing valve core 2 and a valve body plug assembly 4 . Among them, the small valve body 66 is provided with a medium inlet passage 51, a low temperature medium outlet passage 52 and a high temperature medium outlet passage 53; 66 internal communication setting; the temperature-sensitive reversing valve core 2 is set at the position where the three channels in the small valve...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap