A super-compliant segmented stent and its weaving method

A compliance and transition technology, applied in the field of medical equipment, can solve the problems of easy displacement, poor compliance, and poor stent compliance, and achieve the effect of fixing the stent and reducing the displacement of the stent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

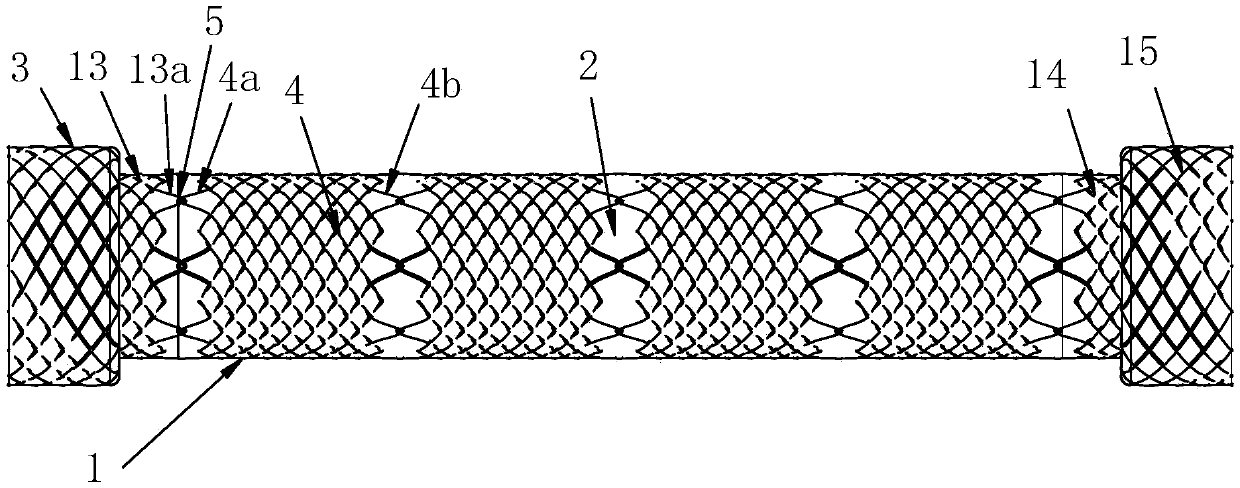

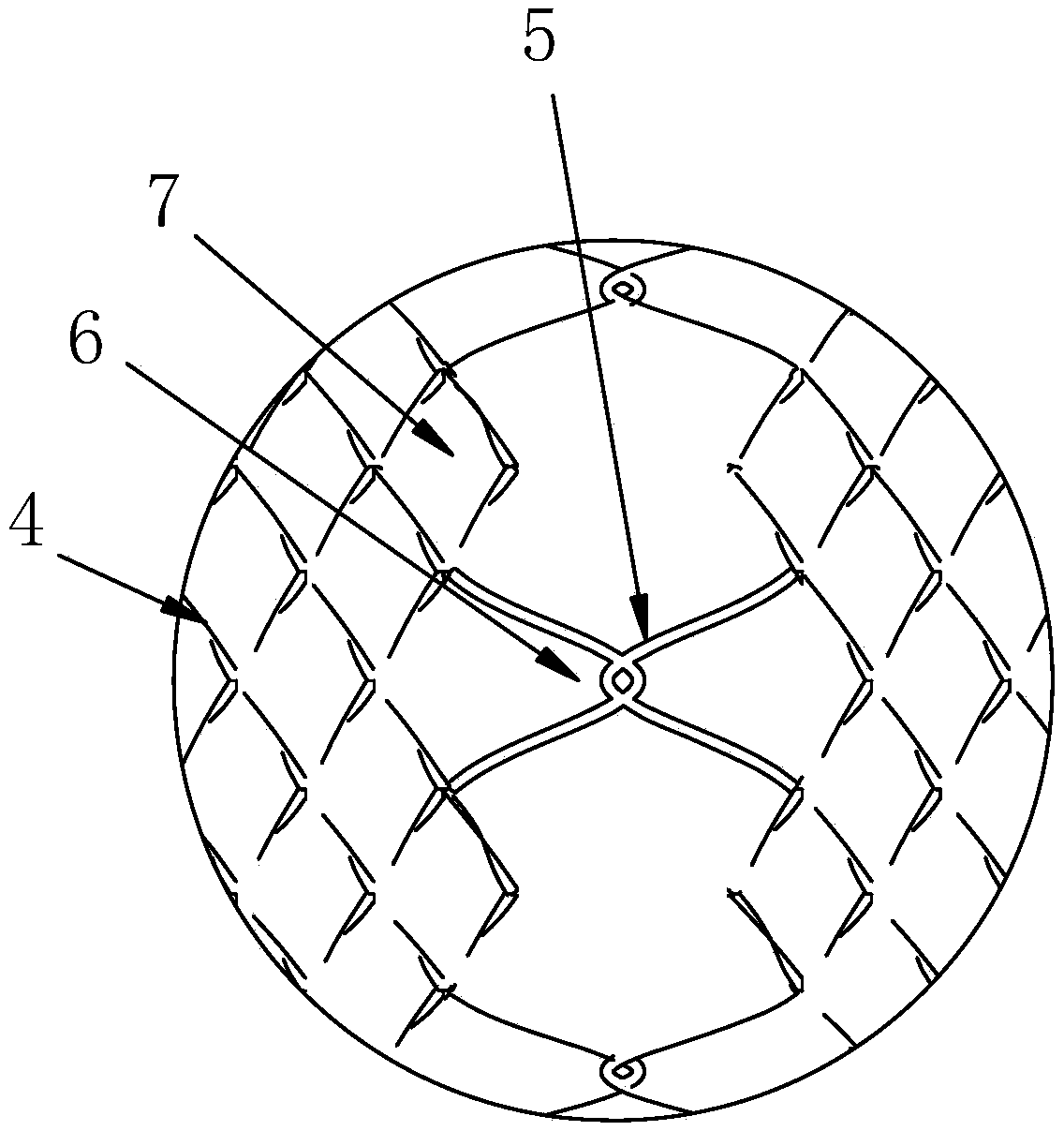

[0032] Such as figure 1 with figure 2 , The connecting structure 2 at one end of the segmented part 4 includes a high pointed head 6 and a low round head 7. The high pointed head and the low round head are alternately arranged at intervals, starting with a high pointed head, in a clockwise direction, and all odd-numbered ends are The high pointed head and the even-numbered head ends are all low round heads, and the high pointed heads are connected to the high pointed heads of the adjacent segments to form the lock structure 5. The single high point is the lock ring 6, and the lock ring and the lock ring are paired to form a lock structure.

[0033] This embodiment also includes a weaving method: including the following steps:

[0034] Step 1: Use wire to knit the cup structure 3 from either end of the bracket until the cup structure is knitted;

[0035] Step 2: Use wire to weave a cup transition section 13, and weave a set of lock rings 13a at the end of the cup transition section;...

Embodiment 2

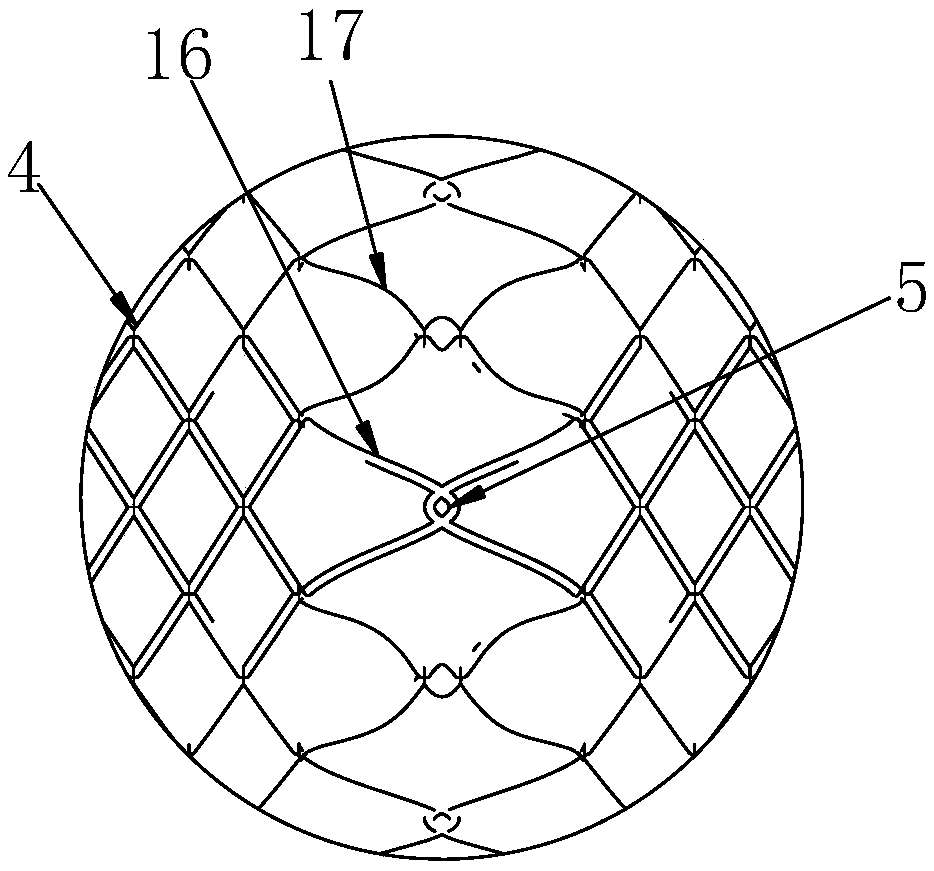

[0042] Such as image 3 , The connecting structure includes an axial high head 16 and a radial high head 17, the axial high head 16 and the radial high head 17 are alternately arranged at intervals, and the axial high heads of two adjacent sections are connected to the axial high head to form a lock Structure, the radial high head is connected to the radial high head to form a lock structure.

Embodiment 3

[0044] Such as Figure 4 , The odd-numbered heads of each segmented stent are woven into high-pointed head 8, and the even-numbered heads are woven into low-pointed head 9. The interconnection between the segmented stents is through the high-pointed head of one segment and the low The pointed ends are connected to each other to form a lock structure 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com