Super compliable recyclable film-covered subsection support and manufacturing method thereof

A compliance and coating technology, applied in the direction of stents, human tubular structure devices, blood vessels, etc., can solve the problems of not being able to fit the human body well, strong foreign body sensation, and lack of compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention also discloses a preparation method of the bracket, which comprises the following steps:

[0028] First insert the cup openings at both ends of the stent body into the corresponding positions of the mantle;

[0029] Apply glue to the cup openings at both ends of the mantle and the bracket body, and fix them by high-temperature vulcanization;

[0030] Insert the segmented parts of more than two connected segments into the mantle;

[0031] Silk threads are used to connect more than two segmental parts to the cup openings at both ends of the bracket body.

[0032] Putting the inner mantle into the stent body, coating the points on the outer wall of the inner mantle with glue, and fixing the stent body and the inner mantle.

[0033] More than two segments of the stent body are impregnated with a liquid polymer material to form a covering film, and then placed in the mantle.

Embodiment 1

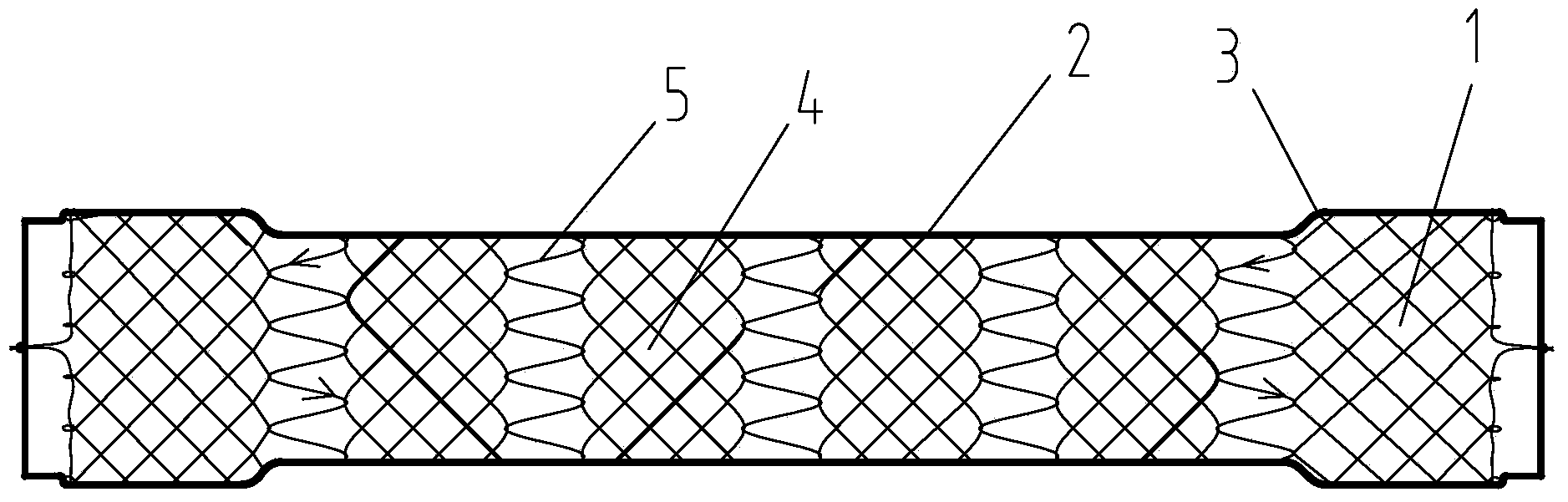

[0035] This embodiment discloses a super-compliant recyclable film-coated segmented stent, which includes the stent cups 1 at both ends and the stent body 2 composed of two or more segmented parts 4 connecting the stent cups 1 at both ends, The inner diameter of the cup mouth part 1 is larger than the inner diameter of the segmented part 4, and the outer part of the stent body 2 is nested with a layer of independent mantle 3 with a mutual movable gap with the segmented part 4; between the segmented parts 4 Connected by wire 5. The inner diameter of the mantle 3 located at the cup mouth portion 1 of both ends of the stent is greater than the inner diameter located at the subsection 4 . Both sides of the mantle 3 exceed the cup opening 1 of the stent, and the diameter of the protruding part is smaller than the diameter of the cup opening 1 of the stent. The thread 5 is a surgical suture.

[0036] The preparation method of the stent of this embodiment comprises the following st...

Embodiment 2

[0042] This embodiment discloses a super-compliant recyclable film-coated segmented stent, which includes the stent cups at both ends and the stent body composed of more than two sections connecting the stent cups at both ends. The inner diameter of the part is larger than the inner diameter of the segmented parts, and an independent outer mantle is nested outside the stent body and has a mutual movable gap with the segmented parts; the segmented parts are connected by silk threads. The inner diameter of the mantle located at the cup openings of the stents at both ends is greater than the inner diameter located at the subsections. The stent body is provided with a layer of independent inner mantle which has a mutual movable gap with the segmented part. Both sides of the mantle exceed the cup mouth of the stent, and the diameter of the excess part is smaller than the diameter of the cup mouth of the stent. More than two segments of the stent body are impregnated with liquid po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com