End cover set of brush direct current motor

A technology of end caps and brushes, applied in the direction of electric components, circuits, collectors, etc., to achieve the effects of easy installation, improved bending angle, and increased irregular deformation force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described in detail below with reference to the drawings.

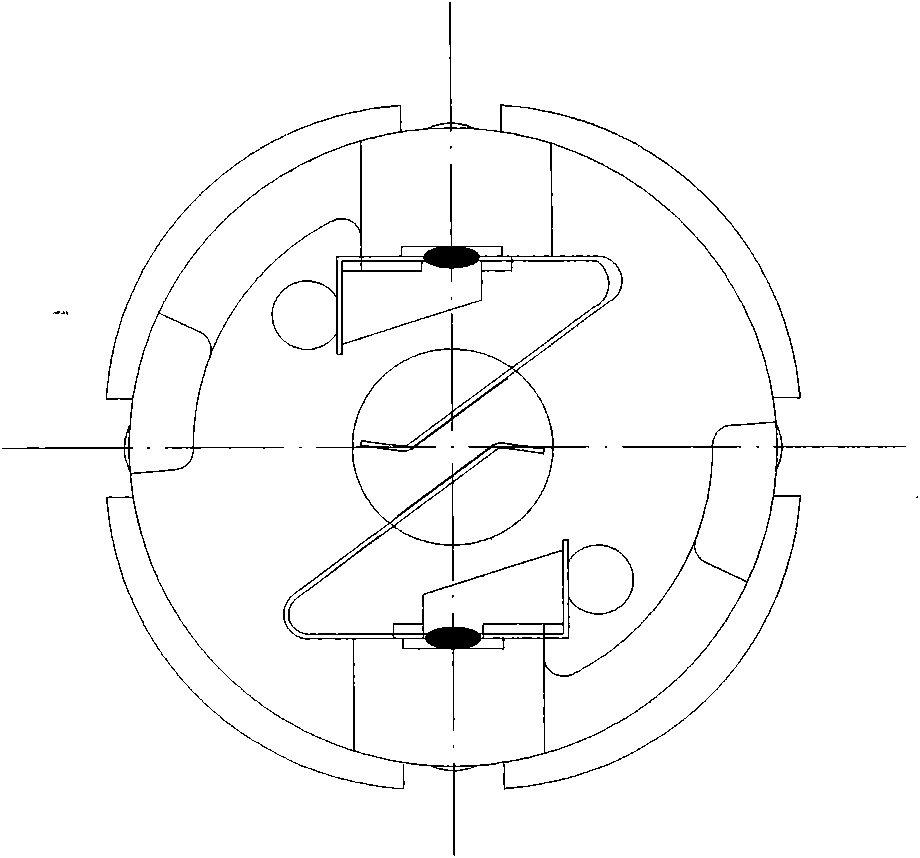

[0025] The overall structure of the brushed DC motor end cover group in the embodiment of the present invention is shown as follows Figure 4 As shown in , the rest of the structure of the motor is not shown in the figure. from Figure 4 It can be seen from the figure that the end cover group of the brushed DC motor is mainly composed of brushes 200 and a plastic cover 300 . The plastic cover is provided with a fixing position 301 and a wire end 302 . The fixing position 301 is used to fix the brush 200 . The wire end 301 is fixed with a wire, which is used to energize the brushes fixed on the plastic cover.

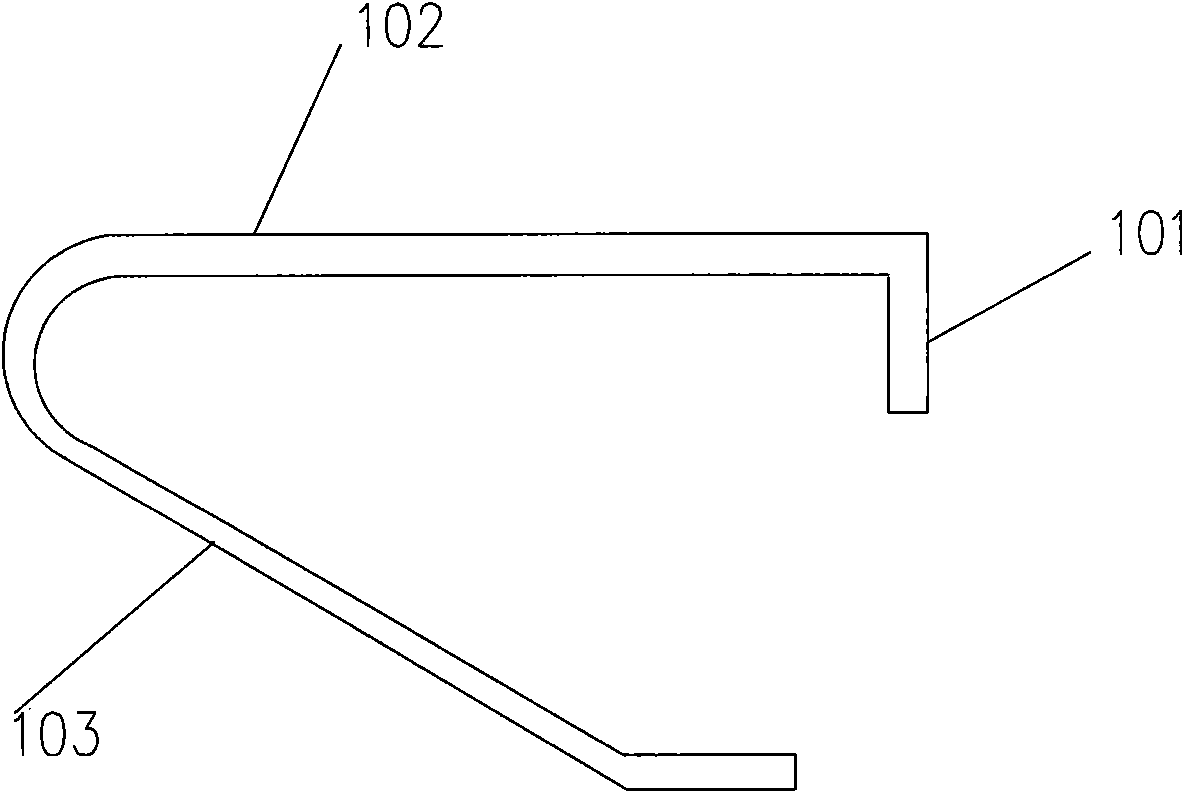

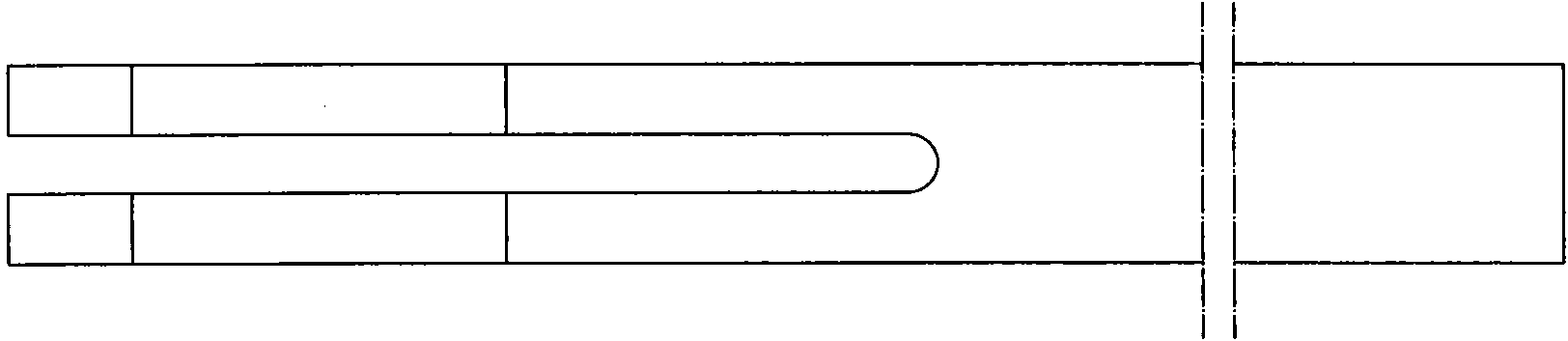

[0026] Figure 5 show Figure 4 The schematic diagram of the structure of the brush 200 in , which is formed by bending a strip of metal, includes a conductive part 201 , a force arm 202 and a brush part 203 . The conductive part 201 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com