Printing method based on circular machine

A printing method and circular machine technology, applied in printing, dyeing, printing machines, etc., can solve the problems of high efficiency, low efficiency, high operating cost and energy consumption, and achieve the effect of low operating cost and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

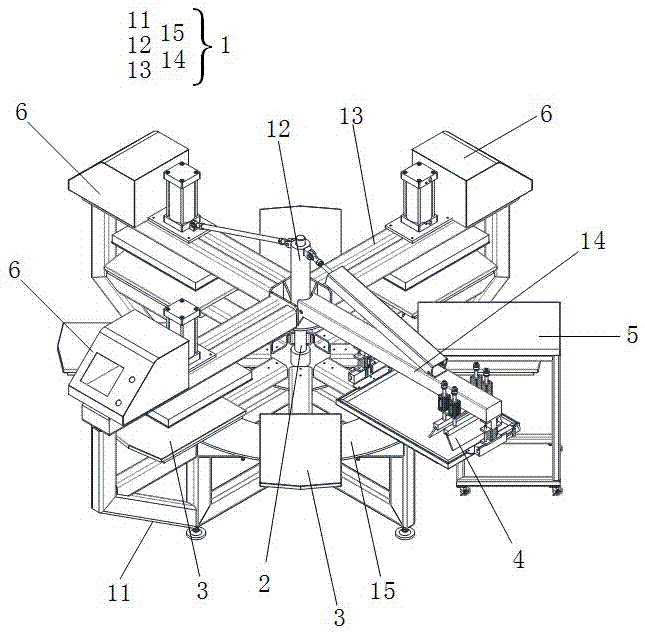

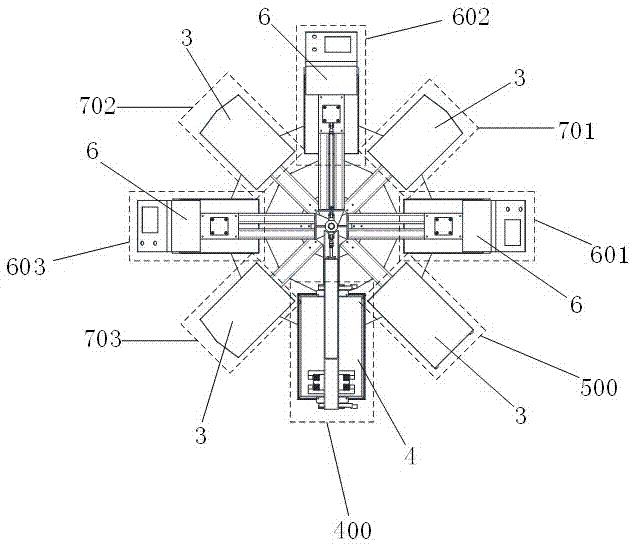

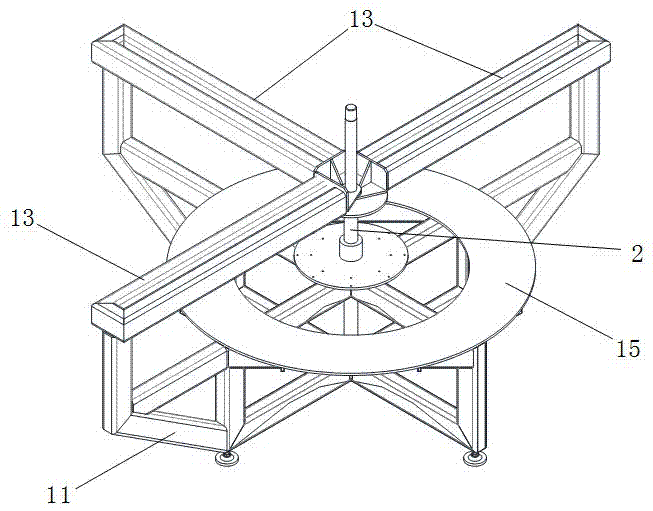

[0031] The following will combine Figure 1 to Figure 6 The printing method based on the circular machine and the circular machine provided by the present invention are described in detail, which is an optional embodiment of the present invention. It can be considered that those skilled in the art will not change the spirit and content of the present invention. Revise and polish it.

[0032] first, combine Figure 1 to Figure 5 The circular machine is described in detail. In an optional embodiment of the present invention, the circular machine includes a fixed frame 1 and a rotating frame 2. The rotating frame 2 includes a central rotating shaft surrounded by several printing tables 3 The central rotating shaft is arranged and rotates with the central rotating shaft, the fixed frame 1 includes a torus structure 15, and the printing table 3 rotates along the torus structure;

[0033] It also includes a squeegee mechanism 4, a flash drying mechanism 5 and a pressing mechanism ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap