Water-cooled motor provided with cast copper rotor

An electric motor and rotor technology, applied in the field of electric motors, can solve the problems of copper bars moving in the slot and hidden dangers of long-term operation of the electric motor, and achieve the effects of improving the overall efficiency, improving the reliability and service life, and reducing the amount of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

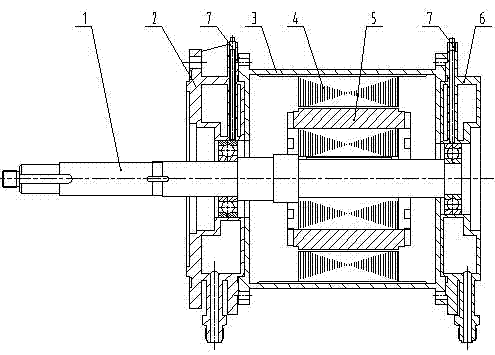

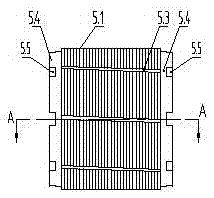

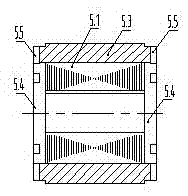

[0020] The water-cooled motor with cast copper rotor shown in the accompanying drawings includes a motor shaft 1, a front end cover 2, a housing 3, a stator 4, a rotor 5, and a rear end cover 6; the rotor 5 includes a rotor core 5.1; the rotor core 5.1 It is formed by stacking several rotor punches 5.2 of the same size and shape; the middle part of the rotor punch 5.2 is provided with a shaft hole, and a number of guide bar holes 5.2.1 are evenly distributed around it, and the guide bar holes 5.2 in each rotor punch 5.2. 1 are stacked and connected to form the guide bar groove in the rotor core 5.1, the guide bar groove is a spiral groove; the guide bar groove is die-cast with a spiral copper guide bar 5.3, and the two ends of the rotor iron core 5.1 are provided with copper end rings 5.4 , the copper end rings 5.4 at both ends of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com