A kind of plant enteric-coated hollow capsule and its production method

A technology of hollow capsules and plant intestines, applied in capsule delivery, pharmaceutical formulations, inorganic non-active ingredients, etc., can solve the problems of lack of surface uniformity, coating peeling and peeling, loss of gelatin capsule shell, etc., and achieve a safe and economical production process , the formula is simple, save the effect of coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

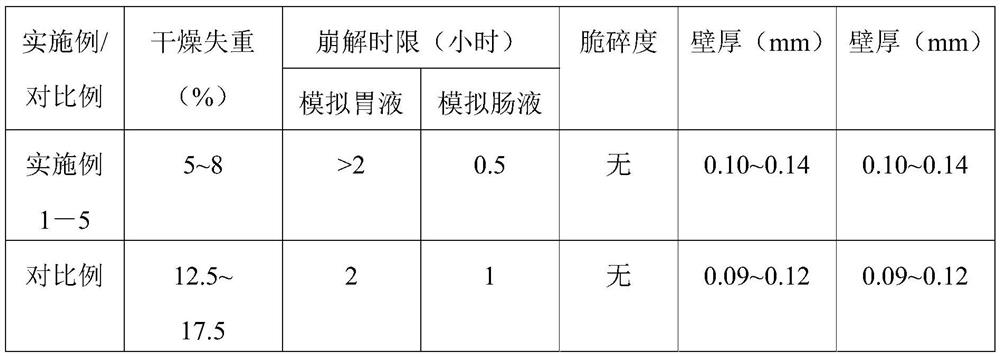

Examples

Embodiment 1

[0038] Add 0.2 parts of potassium citrate, 0.5 parts of alginate, 0.4 parts of carrageenan, 0.2 parts of xanthan gum and 10 parts of hydroxylamine with a dynamic viscosity of 3 to 30 cP in 100 parts of distilled water heated to 85 °C while stirring. Propyl methyl cellulose, the stirring time is 0.5h, add 4 parts of water, under the conditions of temperature 85°C and vacuum degree 0.02MPa, vacuumize and defoam for 2 hours, then cool down to 55°C naturally for 5 hours and then dip in Glue to form a film, cross-link in a calcium chloride solution with a concentration of 5.0wt% for 300s, wash twice, and dry for 2 hours at a relative humidity of 36% and a temperature of 40°C to obtain plant enteric-coated hollow capsules.

Embodiment 2

[0040]Add 4.0 parts of potassium chloride, 2.0 parts of algin, 0.3 parts of gellan gum, 0.3 parts of konjac gum and 20 parts of konjac gum with a dynamic viscosity of 3 to 30 cP in 100 parts of distilled water heated to 85 °C while stirring. Hydroxypropyl starch, the stirring time is 2 hours, 4 parts of water, under the conditions of temperature 85 ℃ and vacuum degree 0.04MPa, vacuumize and remove bubbles for 3 hours, then naturally cool down to 55 ℃ for 3 hours and then dip the glue to form The film was cross-linked in a calcium citrate solution with a concentration of 10.0wt% for 100s, washed 4 times, and dried for 2 hours at a relative humidity of 36% and a temperature of 45°C to obtain plant enteric-coated hollow capsules.

Embodiment 3

[0042] Add 0.5 parts of potassium citrate, 5.0 parts of alginate, 0.3 parts of gellan gum, 0.4 parts of locust bean gum and 10 parts of hydroxybenzene with a dynamic viscosity of 3 to 30 cP in 100 parts of distilled water heated to 90 °C while stirring. Propyl cellulose, the stirring time is 4 hours, 4 parts of water, under the condition of temperature of 85 ℃ and vacuum degree of 0.06MPa, vacuumize and defoam for 2 hours, then naturally cool down to 55 ℃ for 2 hours and dip in the glue to form The film was cross-linked in a calcium lactate solution with a concentration of 5.0wt% for 50s, washed three times, and dried for 4 hours at a relative humidity of 36% and a temperature of 35°C to obtain plant enteric-coated hollow capsules.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap