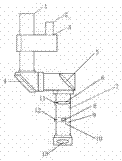

Spot-adjustable laser cladding head

A laser cladding and cladding head technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of changing the focus point of powder feeding and affecting the quality of cladding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: Circular spot cladding.

[0021] The steps are as follows:

[0022] (1) Rotate the rotating shaft 10 of the integrating mirror so that the integrating mirror 8 is at a side position where the beam does not pass through;

[0023] (2) According to actual cladding needs, turn on the focusing mirror lock switch 11, and adjust the position of the focusing mirror 6 in the main body 7 of the cladding head until the optimum spot diameter is obtained. If it is necessary to obtain a cladding spot with a smaller diameter, the focusing lens 6 is placed at the upper position of the cladding head body 7; lower position;

[0024] (3) Turn off the focusing mirror lock switch 11 so that the focusing mirror 6 is fixed at a certain position inside the main body 7 of the cladding head.

Embodiment 2

[0025] Embodiment 2: Rectangular spot cladding.

[0026] The steps are as follows:

[0027] (1) Rotate the rotating shaft 10 of the integrating mirror so that the integrating mirror 8 is in the central position where the beam passes;

[0028] (2) According to actual cladding needs, turn on the locking switch 11 of the focusing mirror, and adjust the position of the focusing mirror 6 in the main body 7 of the cladding head until the optimum spot diameter is obtained; you can also turn on the locking switch 12 of the integrating mirror , adjust the position of the integrating mirror 8 in the cladding head main body 7 until the optimum spot diameter is obtained;

[0029] (3) Turn off the focusing mirror locking switch 11 (or integrating mirror locking switch 12 ), so that the focusing mirror 6 (or integrating mirror 8 ) is fixed at a certain position in the main body 7 of the cladding head.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com