Coupling automatic pre-screwing machine

A pre-tightening and automatic technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve problems that affect the strength and sealing of threaded connections, squeeze out oil, and stick buttons, etc., to save labor costs and improve production The effect of work efficiency and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

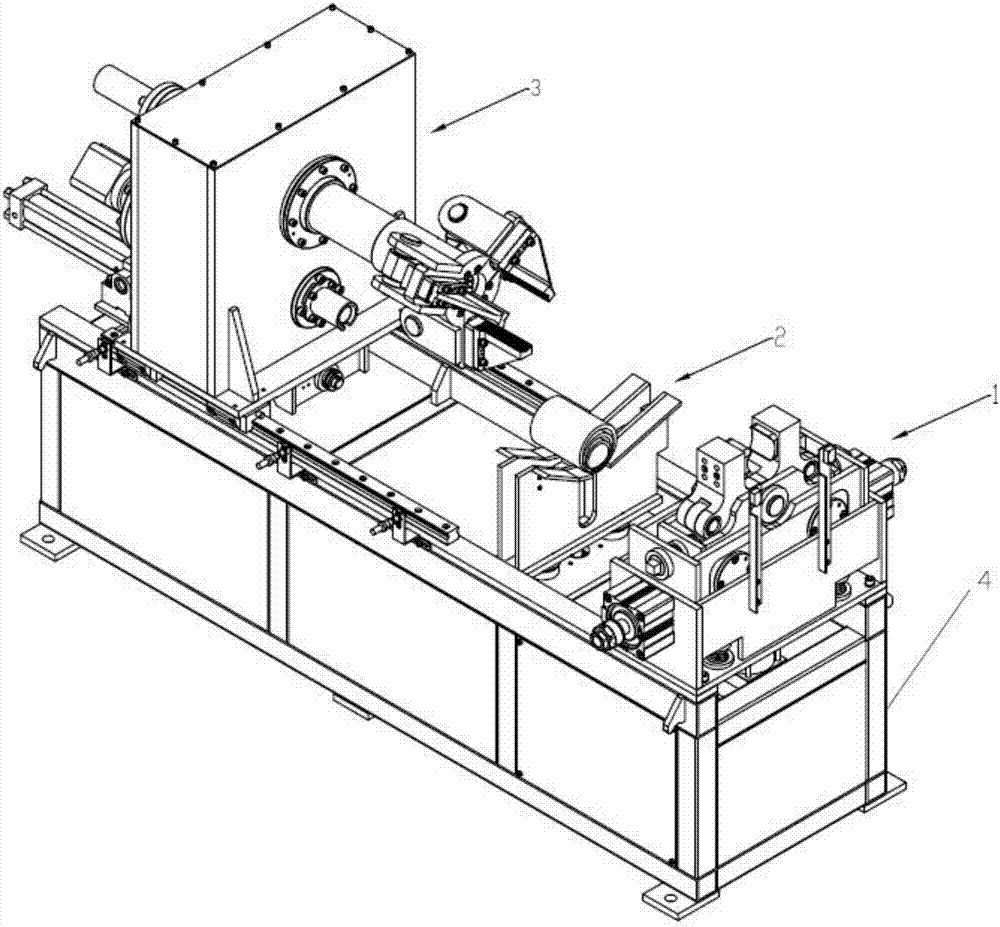

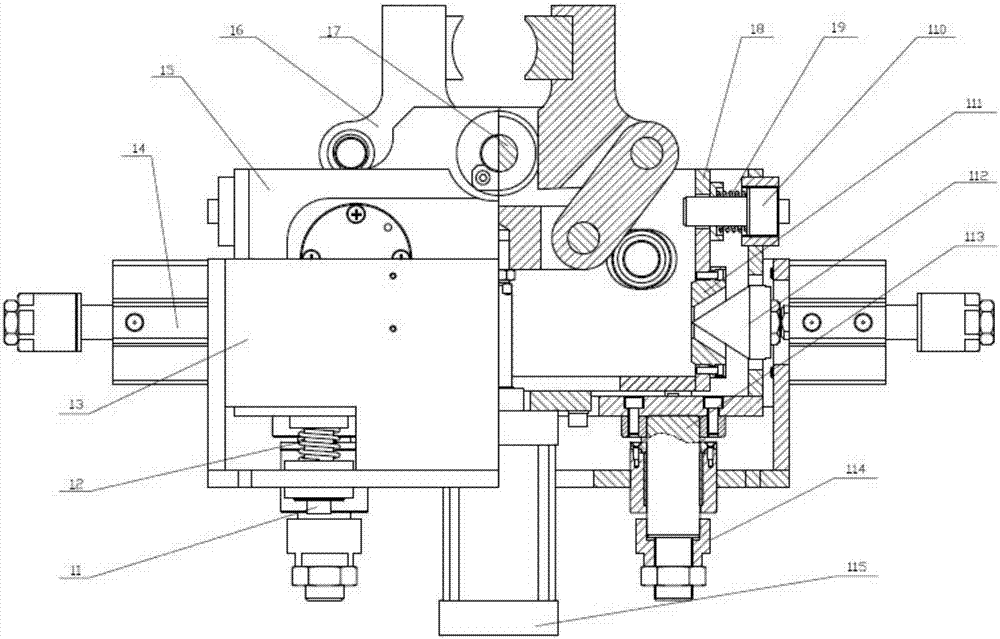

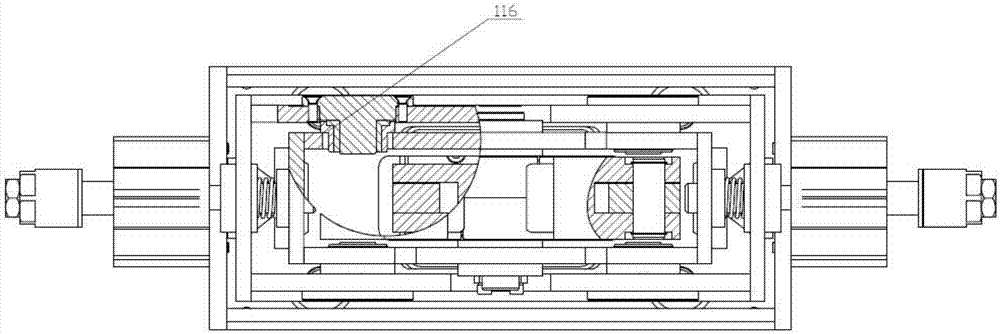

[0028] Examples, such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, and 9, a coupling automatic pre-twisting machine includes a frame body 4, and the top of the frame body 4 is sequentially provided with floating back clamps from one side to the other side 1. Coupling support frame 2, main tong 3; after the oil pipe to be screwed reaches the pre-tightening station, the floating back tong 1 clamps one end of the oil pipe, and the cylinder of the floating back tong centering mechanism moves to center the oil pipe at the predetermined position , the coupling to be twisted is lifted by the coupling support frame 2, concentric with the main tongs main shaft, the main tongs 3 quickly reach the coupling clamping position under the push of the oil cylinder 39, the clamping oil cylinder moves, the main tongs 3 clamp the coupling, and connect The hoop support frame 2 falls, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com