Automatic container car loader

A container and loading machine technology, applied in the direction of transportation, packaging, loading/unloading, etc., can solve the problems that the containers cannot be fully stacked, the turning height is large, and the items in the box are damaged, so as to realize automatic loading and reduce the remaining space , The effect of improving loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

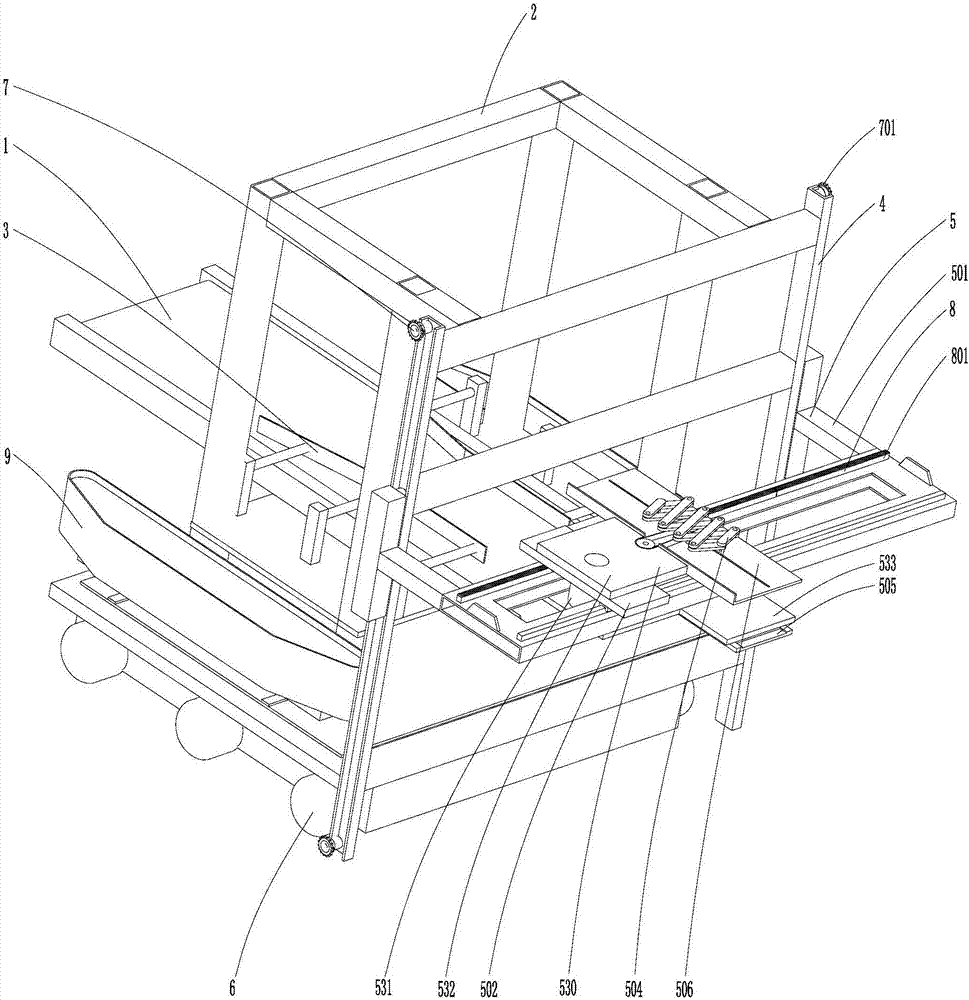

[0049] This embodiment provides a container automatic loading machine, such as figure 1 As shown, it includes a conveyor belt 1, a frame 2, a packing box guiding mechanism 3, a lifting guide rail 4, a loading mechanism 5, a wheel 6, a lifting driving mechanism 7, a translation driving mechanism 8, a rotating driving mechanism and a Guide track 9 for wall contact.

[0050] The frame 2 is provided with a packing box guide mechanism 3 and a lifting guide rail 4. The frame 2 is hinged with the end of the conveyor belt 1. The packing box guiding mechanism 3 is installed on the frame 2 and arranged on both sides of the conveyor belt 1. The lifting guide rail 4 is installed vertically on the rack 2.

[0051] The loading mechanism 5 includes a lifting platform 501, a horizontal base 502, a rotating base 530, a push-pull mechanism, a slide block 505 with a packing box suction cup and a pallet 506 with a packing box clamping device, the lifting platform 501 and the lifting guide rail 4...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap