Oven with high working efficiency

A work efficiency, drying oven technology, applied in drying, drying machine, drying machine for static materials, etc., can solve the problems of air tightness defect of the drying oven, increase production cost, poor drying effect, etc., and reduce drying Time, cost saving, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

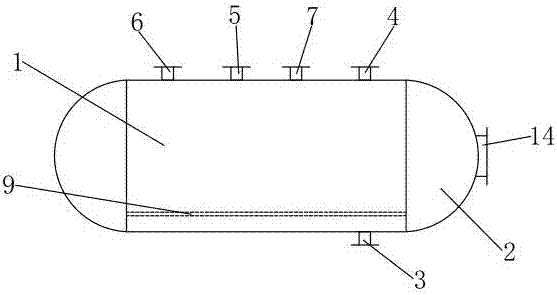

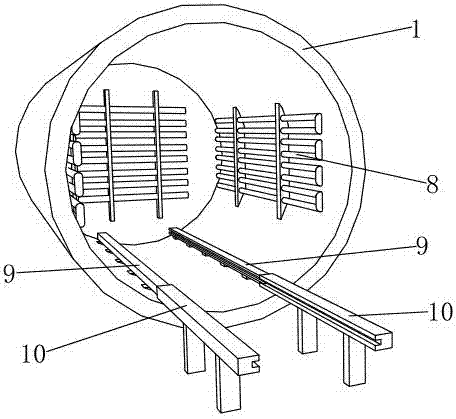

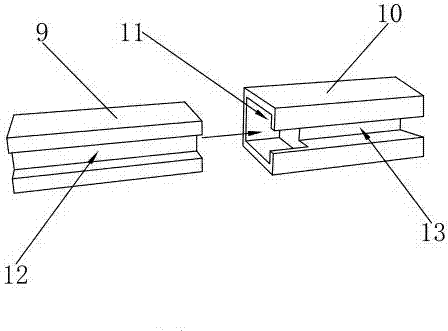

[0018] Such as Figure 1 to Figure 3 As shown, it is a high-efficiency oven of the present invention, including a box body 1, and one side of the box body 1 is rotatably connected with a box door 2, and the box door 2 is provided with a handle 14, which is convenient for opening and closing the box door 2. The other side of the body 1 is sealed and welded firmly, forming an elliptical double-head structure as a whole, which is closed in both directions and has good airtightness. The bottom of the box body 1 is provided with a sewage outlet 3, and the top of the box body 1 is respectively provided with a vent port 4, a vacuum port 5, a pressure measurement port 6 and a temperature measurement port 7. The sewage outlet 3 is used to discharge the waste generated during the drying process. For waste liquid, the vent port 4 is used to discharge gas to ensure a constant pressure in the box body 1 and avoid overpressure. The vacuum port 5 is used to evacuate the non-condensable gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com