High temperature resistance annular encapsulation fiber bragg grating sensor applied to switchgear

A fiber grating, high temperature-resistant technology, applied in the field of smart grid online monitoring equipment, can solve the problems of creeping static electricity, inaccurate measurement results, and complicated installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

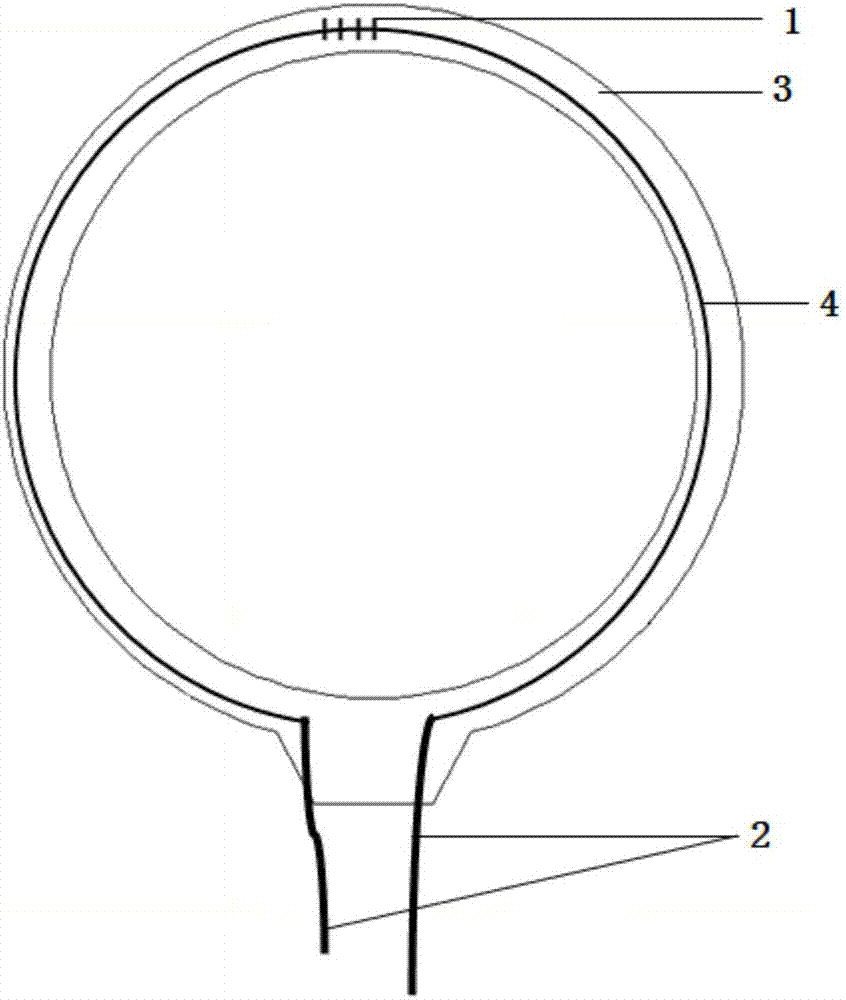

[0011] The present invention provides a kind of high temperature resistant annular package fiber grating sensor for switchgear, such as figure 1 As shown in the structure, the sensor is a new type of fiber grating sensor for switch cabinet temperature measurement with strong applicability.

[0012] Such as figure 1 The high-temperature-resistant ring-shaped fiber grating sensor for switch cabinets shown includes a grating temperature sensing area 1 and an optical fiber. The optical fiber includes a main optical fiber 4, a guide optical fiber and a pigtail 2 located at both ends of the main optical fiber 4, and the grating temperature sensor Zone 1 is encapsulated in Teflon high temperature resistant sleeve 3, the surface of the guide fiber and pigtail 2 is encapsulated with T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com