Drawing production method for aluminum cladding optical unit and tool device corresponding to same

A production method and optical unit technology, applied in wire drawing dies and other directions, can solve problems such as unfavorable health of employees, consumption of large n-bromopropane, and on-site environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

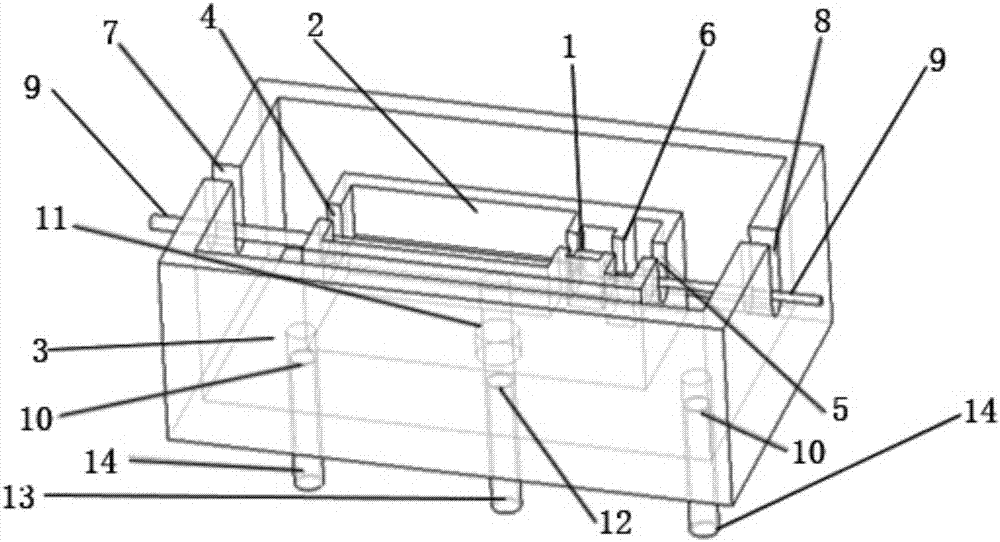

Image

Examples

Embodiment Construction

[0017] The drawing production method of the aluminum-clad light unit: the drawing position of the drawing die is placed in an environment full of water, and the aluminum tube to be drawn is formed once through the drawing position of the drawing die in an environment surrounded by water. The aluminum-clad light unit of the corresponding diameter after drawing is required to complete the drawing and direct take-up under the action of the rear take-up traction.

[0018] The mold core at the drawing position of the drawing die is a nano-diamond composite coating mold. After the surface of the nano-diamond composite coating of the mold core is polished, the surface roughness reaches Ra≤0.1μm, which has self-lubricating properties and is close to the wetting angle of water. 0°, which makes the material very hydrophilic. The hydrophilic property of the working surface makes the water form a continuous lubricating film, and the self-lubricating graphite structure is evenly distributed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface finish | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com