Strip-type steel rust removal device

A steel and bar-shaped technology, which is applied in the field of bar-shaped steel derusting devices, can solve problems such as potential safety hazards, rusting of steel, and economic losses, and achieve the effects of reducing work intensity, liberating manpower, and fast derusting speed

Active Publication Date: 2017-07-04

SHAN DONG JUXIN GRP STEEL STRUCTURE CO LTD

View PDF7 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Nowadays, with the continuous development of society, people's demand for steel products has also increased. When steel products are purchased, they will be stored and placed. However, some steel products will rust during the storage and placement process, causing economic losses. In order to avoid economic losses, rust removal will be carried out, but manual rust removal is time-consuming and labor-intensive, and long-term work will cause work fatigue, hidden safety hazards, and very troublesome. In view of this, the inventor of this case conducted in-depth research on the above problems, and then came to this case produce

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0022] Embodiment 2: The brush layer in the device can be replaced by a sponge layer, and the same effect can be achieved with the rest of the structure unchanged.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

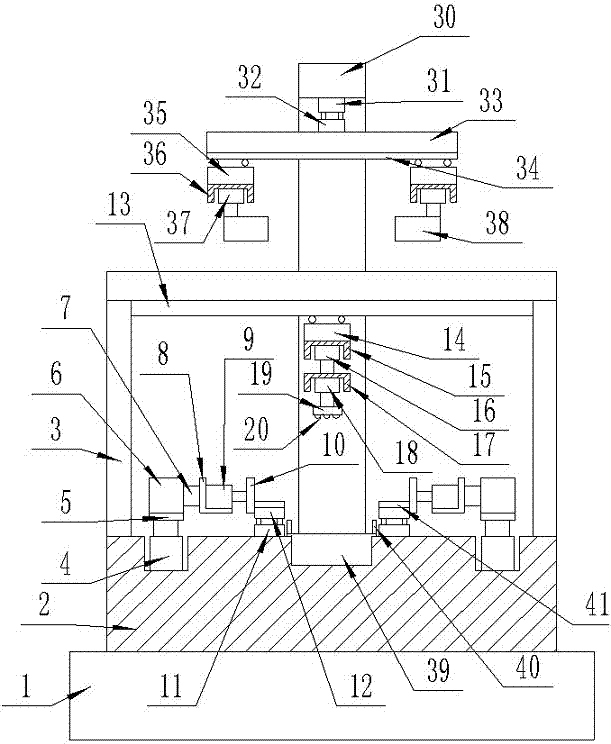

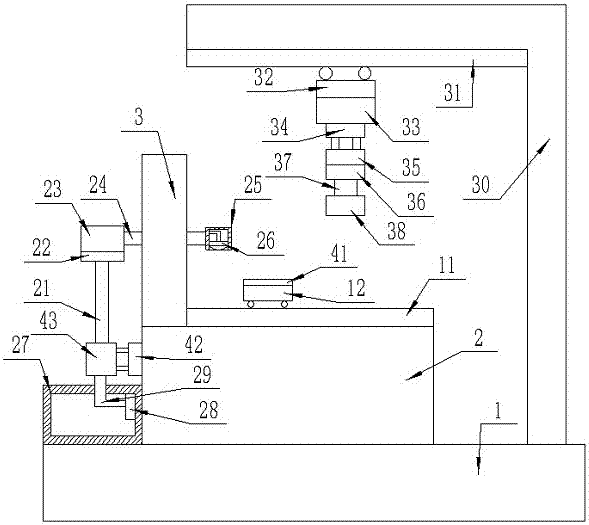

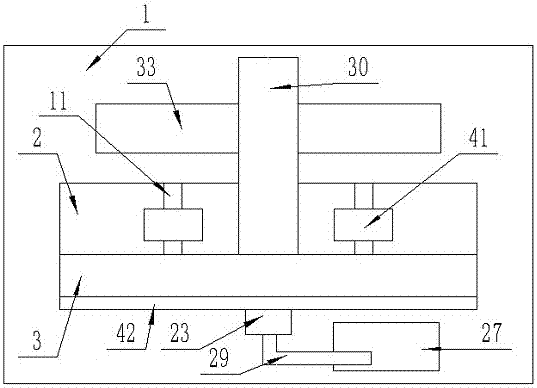

The invention discloses a strip-type steel rust removal device which comprises a working table. A carrying mechanism and a dust removal mechanism are arranged on the upper surface of the working table. The strip-type steel rust removal device has the beneficial effects that rust removal is automatically accelerated, rotation can be achieved while dust removal is carried out, dust removal is more comprehensive, the dust removal speed is high, the manpower is liberated, the working intensity is reduced, feeding and discharging are automatic, the working efficiency is improved, and use is convenient.

Description

technical field [0001] The invention relates to the field of derusting bar-shaped steel materials, in particular to a bar-shaped steel material derusting device. Background technique [0002] Nowadays, with the continuous development of society, people's demand for steel products has also increased. When steel products are purchased, they will be stored and placed. However, some steel products will rust during the storage and placement process, causing economic losses. In order to avoid economic losses, rust removal will be carried out, but manual rust removal is time-consuming and labor-intensive, and long-term work will cause work fatigue, hidden safety hazards, and very troublesome. In view of this, the inventor of this case conducted in-depth research on the above problems, and then came to this case produce. Contents of the invention [0003] The purpose of the present invention is in order to solve the above-mentioned problem, has designed a kind of strip steel deru...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23G3/00C23G5/00

CPCC23G3/00C23G5/00

Inventor 陈清尧

Owner SHAN DONG JUXIN GRP STEEL STRUCTURE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com