Steel shot rust removing device

A technology of steel shot and rust remover, which is applied to grinding machines, surface polishing machine tools, metal processing equipment, etc., can solve the problems of large mechanical wear, high use cost, affecting production efficiency, etc., so as to reduce damage and improve production efficiency. , The effect of low mechanical maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

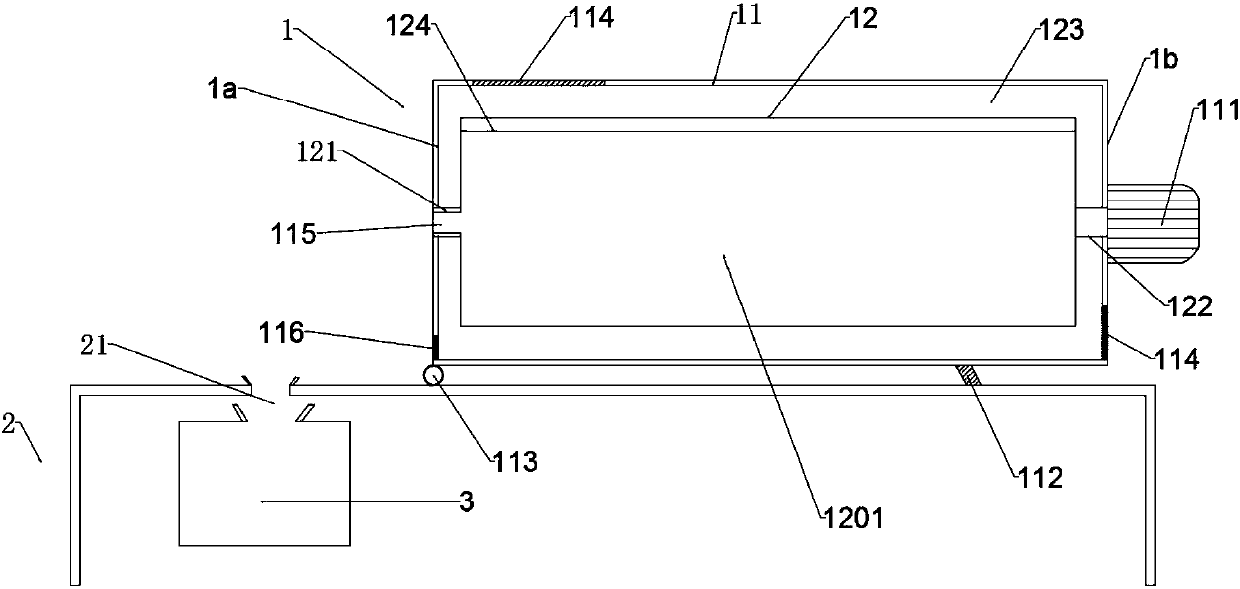

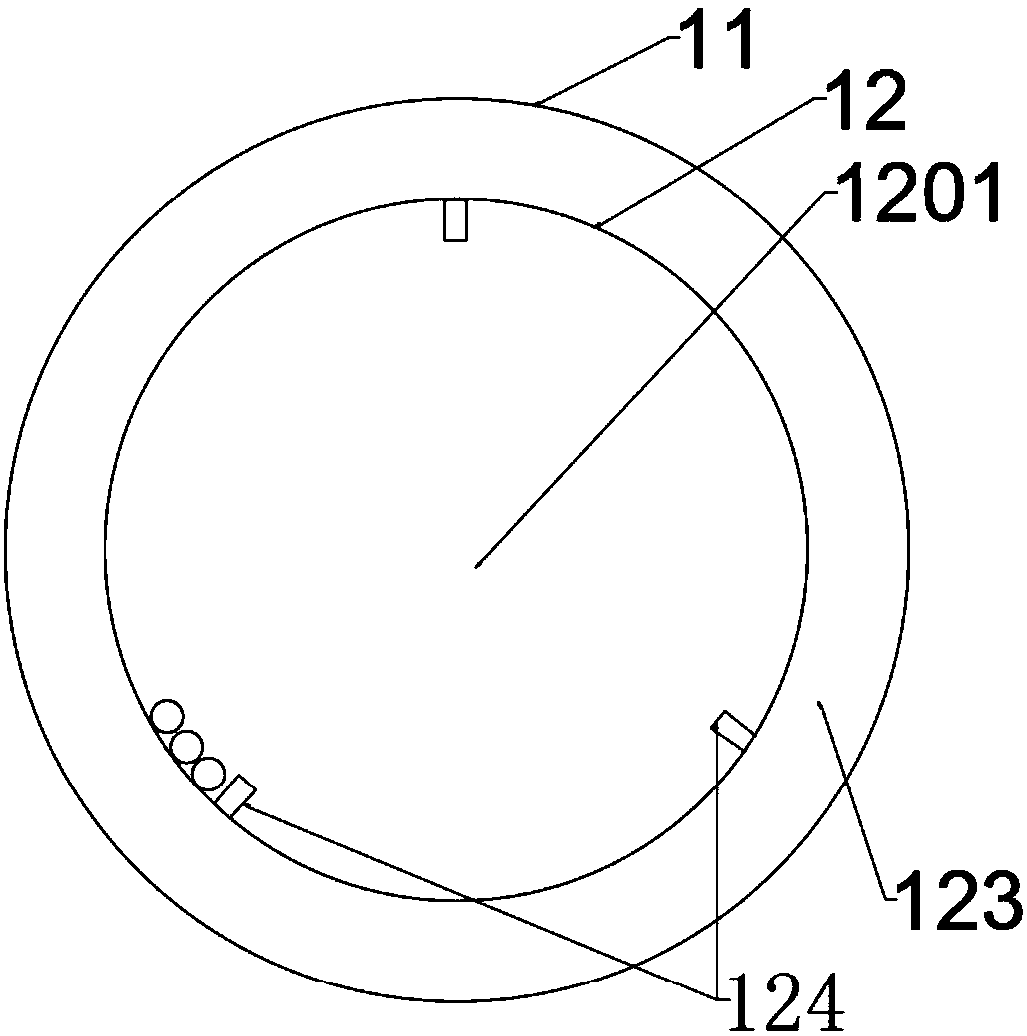

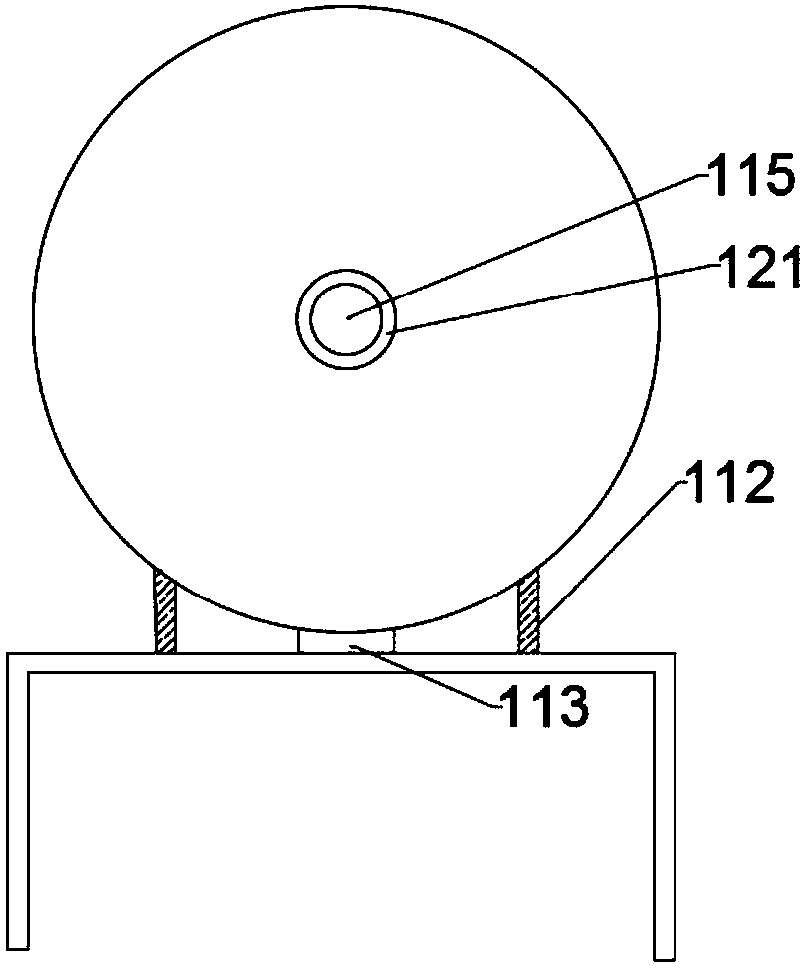

[0022] Such as Figure 1-4 As shown, the derusting machine 1 is composed of a cylindrical rolling outer shell 11 and a rolling inner shell 12, and the rolling inner shell 12 is arranged in the rolling outer shell 11. The two top surfaces of the rolling shell 11 are respectively the first side cover 1a and the second side cover 1b, the first side cover 1a is provided with a material opening 115 and a waste material opening 116, and the second side cover 1b is provided with a rotating motor 111 and an observation port 114 . The rolling inner shell 12 and the rolling outer shell 11 are connected through the first rotating shaft 121 and the second rotating shaft 122. Turn the motor 111.

[0023] The inside of the rolling inner shell 12 is a derusting bin 1201, and the first rotating shaft 121 is a central structure. The derusting bin 1201 communicates with the external space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com