Heat exchange device and heat exchanger

A technology of heat exchange device and heat exchanger, which is applied in the field of heat exchange, and can solve the problems of large installation space and troublesome installation of heat exchangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

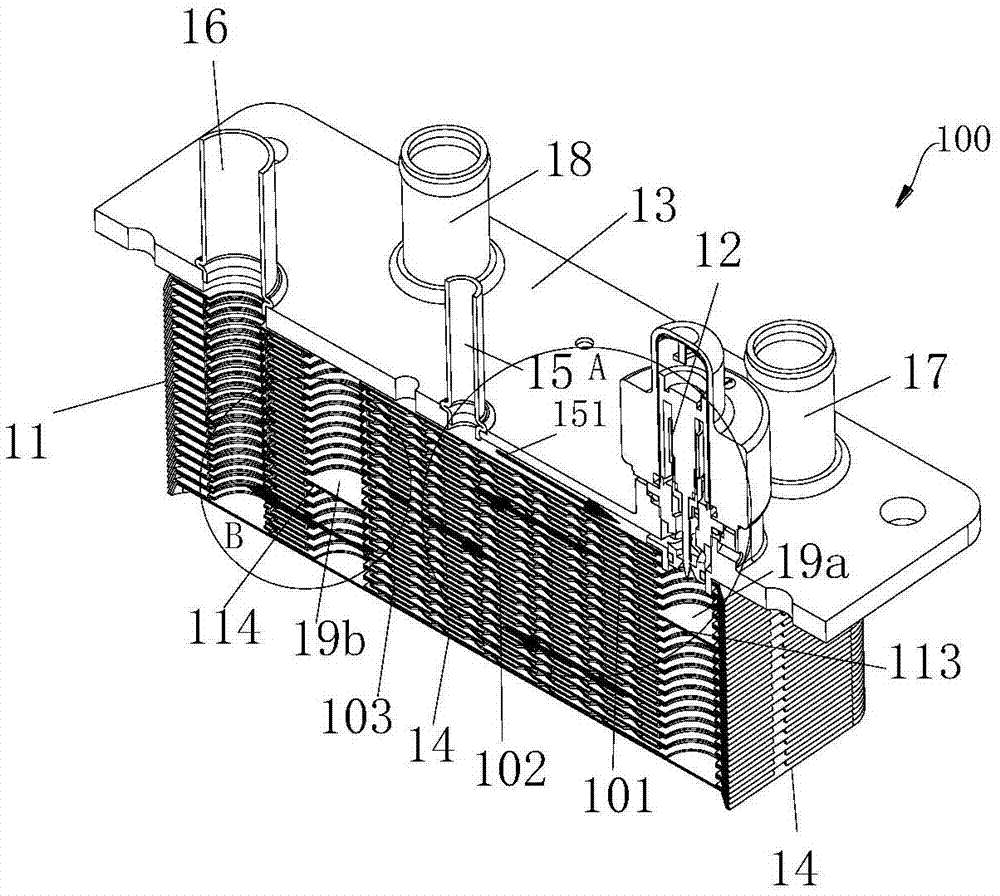

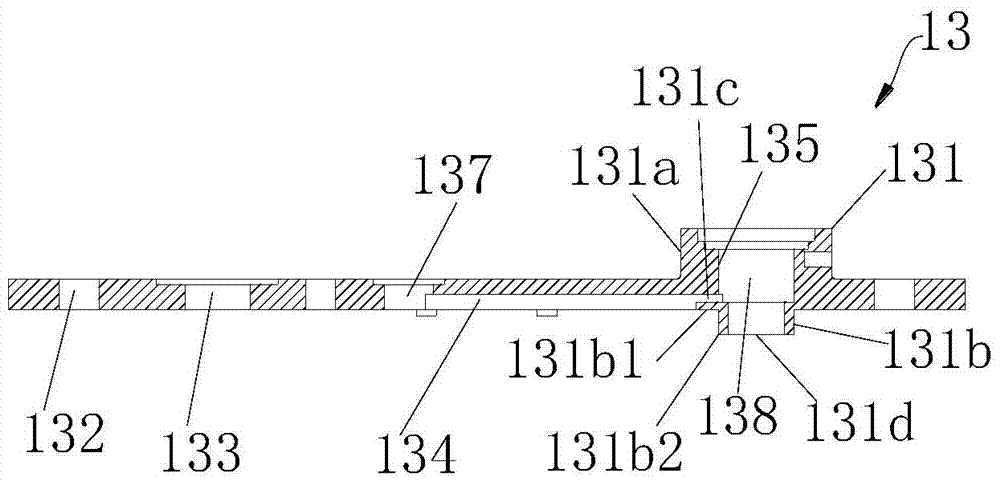

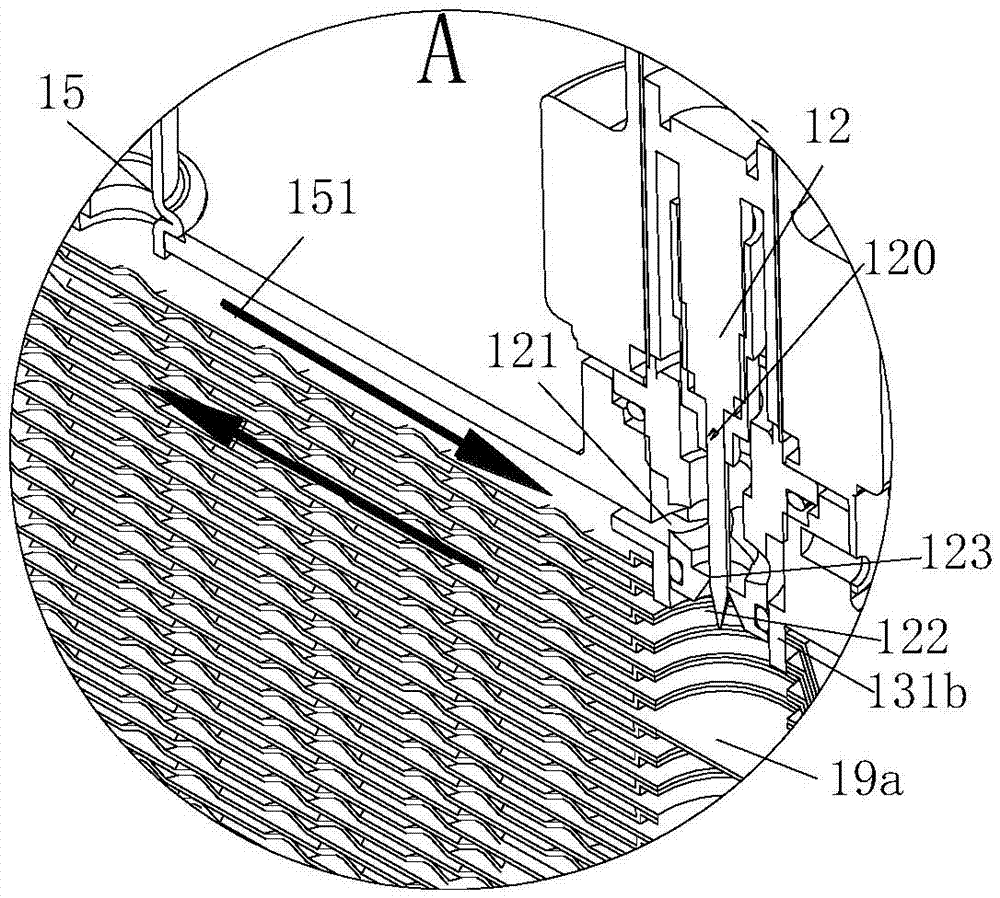

[0046] Reference figure 1 , figure 1 It is a schematic diagram of the three-dimensional structure of an embodiment of the heat exchange device. The heat exchange device 100 includes a heat exchanger core 11, a valve assembly 12, a mounting plate 13, a top plate (not shown), a bottom plate 14, a first outer pipe 15, a second outer pipe 16, a third outer pipe 17, and a fourth outer pipe. Take over 18. The two sides of the heat exchanger core 11 are respectively abutted by the top plate and the bottom plate 14, and the mounting plate 13 abuts against the top plate. Reference figure 2 , The mounting plate 13 includes a plurality of mounting holes 132, a first through hole 137 for fixedly installing the first outer tube 15, a second through hole 133 for fixedly installing the second outer tube 16, and a third outer tube for fixed installation. The third through hole (not shown) of the connecting pipe 17 and the fourth through hole (not shown) for fixing the fourth external pipe 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com