Design method of single-cantilever beam frame having self-support structure

A technology of self-supporting structure and design method, which is applied in the field of additive manufacturing, can solve the problems of not easy to remove and reduce the surface quality of the prototype, and achieve the effect of reducing the printing process, excellent and reasonable mechanical structure, and short printing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

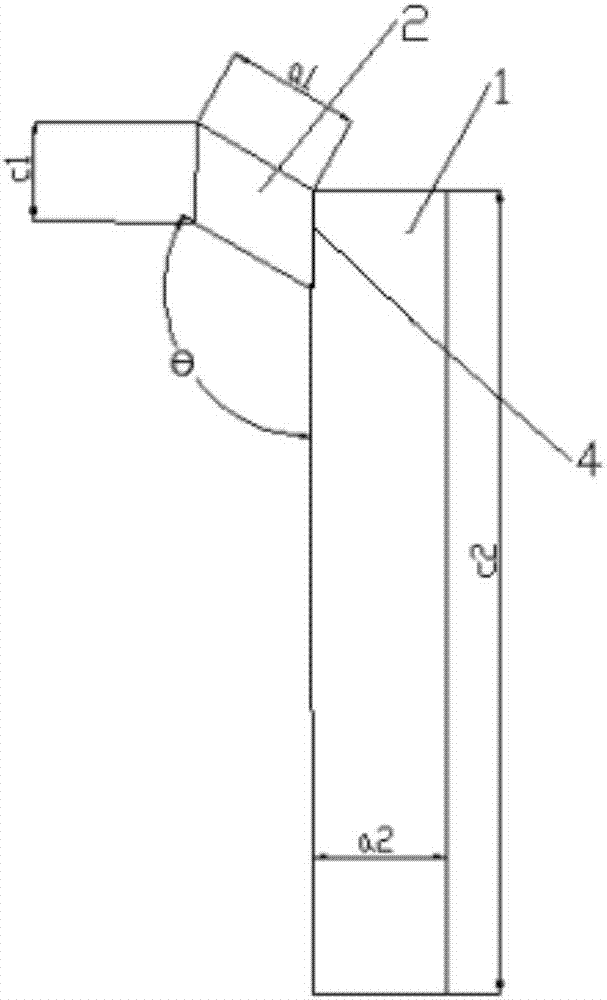

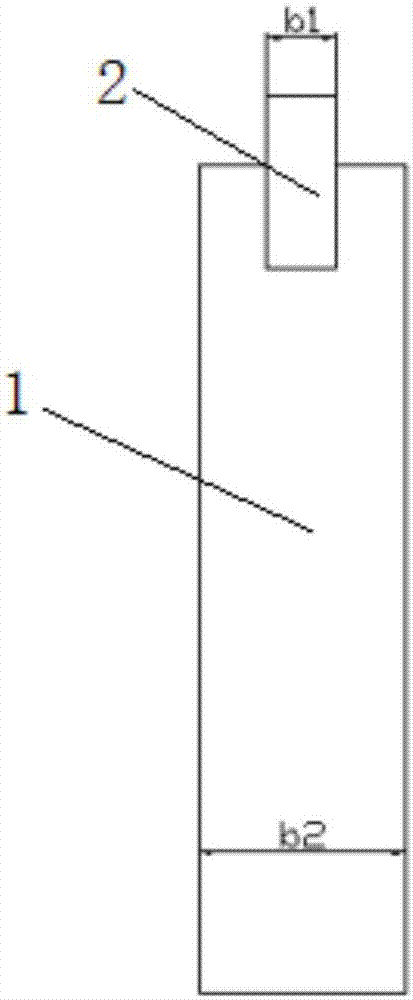

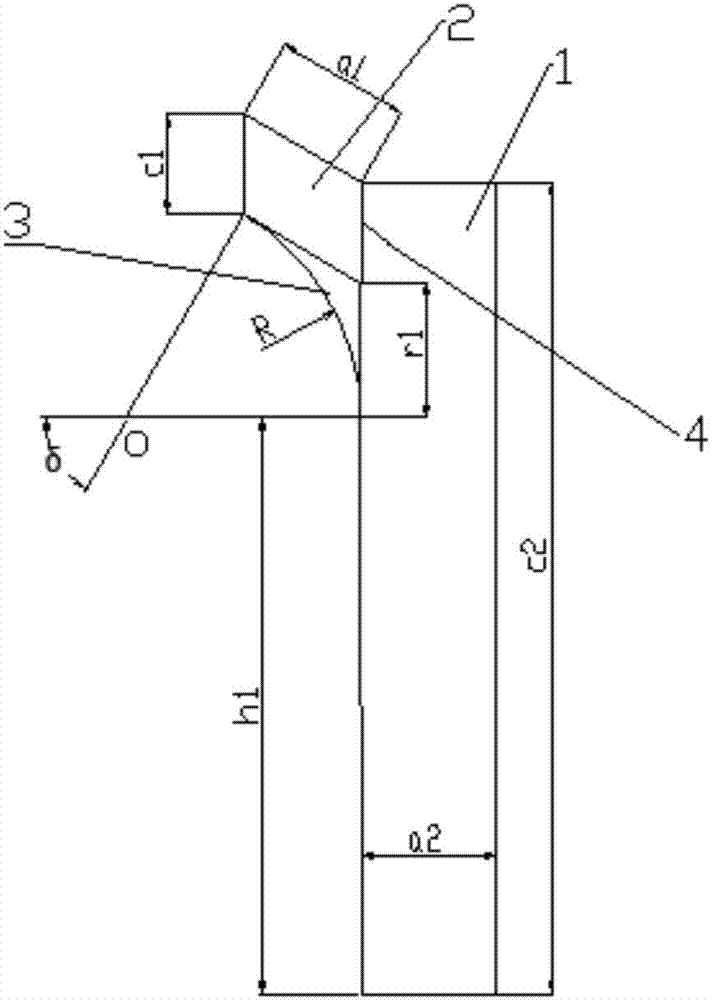

[0103] Set the design parameters of support 1, specifically including: length a 2 =20mm, width b 2 = 30mm and height c 2 = 120mm, design the structure of support 1 according to the above design parameters;

[0104] Set the parameters of the cantilever beam 2, specifically including: length a 1 =60mm, width b 1 =15mm, vertical section height difference c 1 =10mm and the included angle θ=90° between the cantilever beam and the support, design the cantilever beam structure on the top side of support 1 according to the set cantilever beam parameters

[0105] Select the weighting coefficient k of the angle θ between the cantilever beam 2 and the support 1 1 = 3; Calculate the length a of the cantilever beam 2 1 Height c from support 2 ratio of And determine the weighting coefficient k of the ratio s 2 =2; Calculate the weighting coefficient k=k of the self-supporting structure 3 1 k 2 = 4;

[0106] The selected self-supporting structure type is arc, and the single cantil...

Embodiment 2

[0113] Set the design parameters of support 1, specifically including: length a 2 =25mm, width b 2 = 30mm and height c 2 =100mm, design the structure of support 1 according to the above design parameters;

[0114] Set the parameters of the cantilever beam 2, specifically including: length a 1 =30mm, width b 1 =20mm, vertical section height difference c 1 =12mm and the included angle between the cantilever beam and the support θ=90°, design the cantilever beam structure on the top side of the support 1 according to the set cantilever beam parameters

[0115] Select the weighting coefficient k of the angle θ between the cantilever beam 2 and the support 1 1 = 3; Calculate the length a of the cantilever beam 2 1 Height c from support 2 ratio of And determine the weighting coefficient k of the ratio s 2 =2; Calculate the weighting coefficient k=k of the self-supporting structure 3 1 k 2 = 6;

[0116] The selected self-supporting structure type is an elliptical arc; a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com