Design method for statically indeterminate fixed beam frame with self-supporting structure

A self-supporting structure and design method technology, applied in the field of additive manufacturing, can solve the problems of reducing the surface quality of the prototype, increasing the printing time, and not easy to remove, achieving the effect of excellent and reasonable mechanical structure, reducing printing process, and short printing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

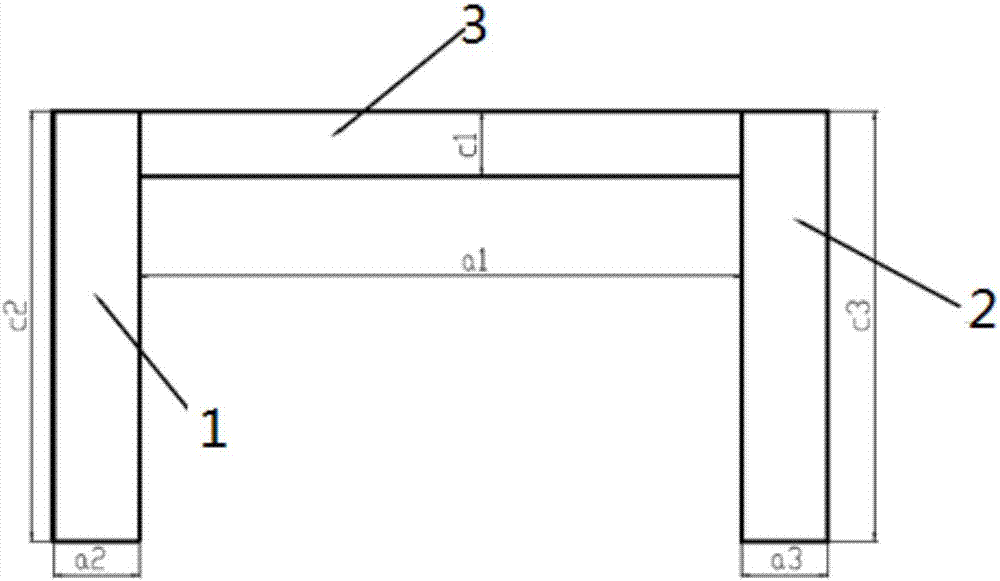

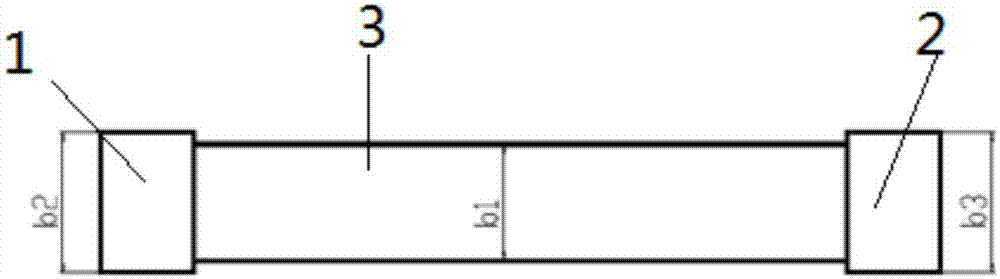

[0067] Set the same design parameters of support a1 and support b2: the length a of support a1 2 equal to the length a of the support b2 3 =20mm, width b of support a1 2 equal to the width b of the support b2 3 = 30mm, the height c of the support a1 2 equal to the height c of the support b2 3 = 100mm; According to the parameters of support a1 and support b2, the structure of support a1 and support b2 can be designed;

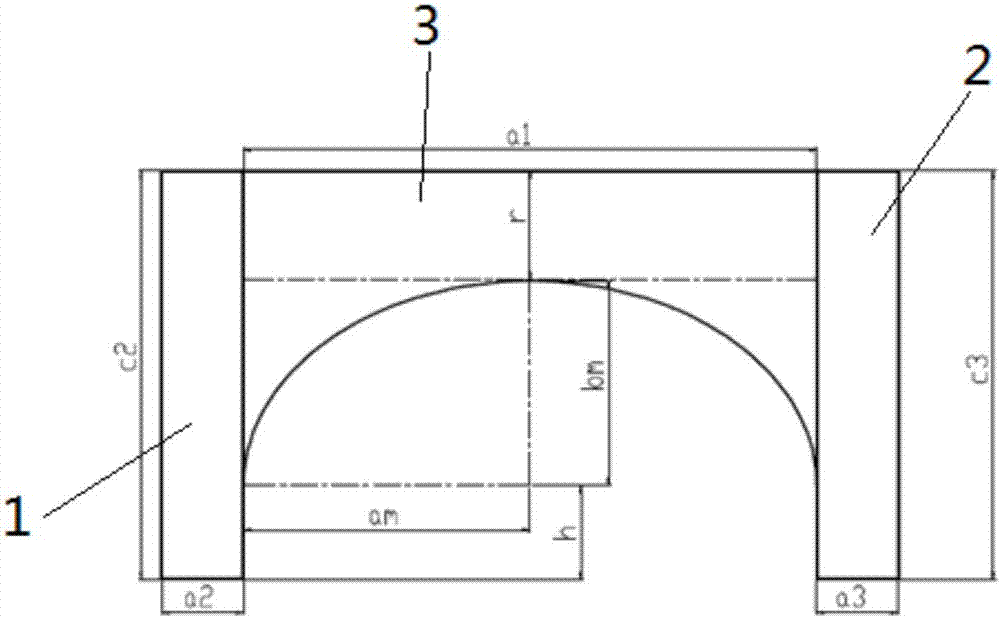

[0068] Set the parameters of fixed-end beam 3 as: a 1 =140mm,b 1 = 25mm, c 1 = 15mm, the external equivalent load f of the fixed end beam 3 = 300N, the fixed end beam 3 is designed between the support a1 and the support b2 according to the design parameters of the fixed end beam 3, since the material of the fixed end beam is polylactic acid material, The flexural modulus E of the polylactic acid material is 100MPa~150MPa, take the flexural modulus E=100MPA, and use the following formula to calculate the allowable thickness [r] from the top of the ellipse ...

Embodiment 2

[0075] Set the same design parameters of support a1 and support b2: the length a of support a1 2 equal to the length a of the support b2 3 =20mm, width b of support a1 2 equal to the width b of the support b2 3 = 30mm, the height c of the support a1 2 equal to the height c of the support b2 3 =80mm; According to the parameters of support a1 and support b2, the structure of support a1 and support b2 can be designed;

[0076] Set the parameters of fixed-end beam 3 as: a 1 =80mm,b 1 = 15mm, c 1 = 10mm, the external equivalent load f of the fixed end beam 3 = 120N, the fixed end beam 3 is designed between the support a1 and the support b2 according to the design parameters of the fixed end beam 3, since the material of the fixed end beam is polylactic acid material, The flexural modulus E of the polylactic acid material is 100MPa~150MPa, take the flexural modulus E=100MPA, and use the following formula to calculate the allowable thickness [r] from the top of the ellipse arc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com