Treble folded and mid-bass folded integrated diaphragm

A technology of bass diaphragm and treble, applied in the direction of speaker diaphragm shape, non-planar diaphragm/cone, diaphragm structure, etc., to achieve the effects of reducing distortion, reducing hysteresis distortion and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

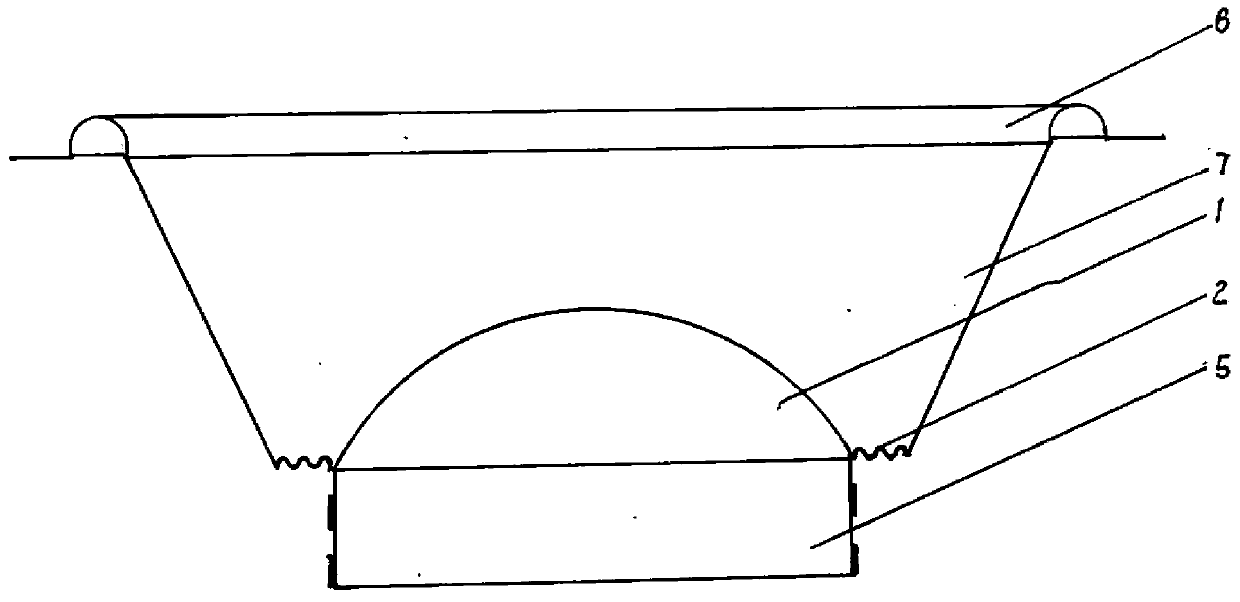

[0022] Conical integrated diaphragm once finalized: see illustration figure 1 . The integrated diaphragm is pressurized and molded with the same material as a whole. The main body of the treble diaphragm, the treble fold, the main body of the mid-bass diaphragm, and the fold of the mid-bass are integrated into one, naturally forming a whole diaphragm with the same structure and the same work. In such a diaphragm, the moving coil is located in the lower (bottom) part, and is directly bonded to the junction of the main body of the treble diaphragm and the treble fold, the main body of the treble diaphragm is in the middle, and the mid-bass diaphragm and the fold are in the upper part. While the vibration of the moving coil directly reaches the main body of the treble diaphragm, it is transmitted to the main body of the mid-bass diaphragm through the treble fold to realize simultaneous and synchronous vibration—synchronous facsimile. This example reduces the overall quality of ...

Embodiment 2

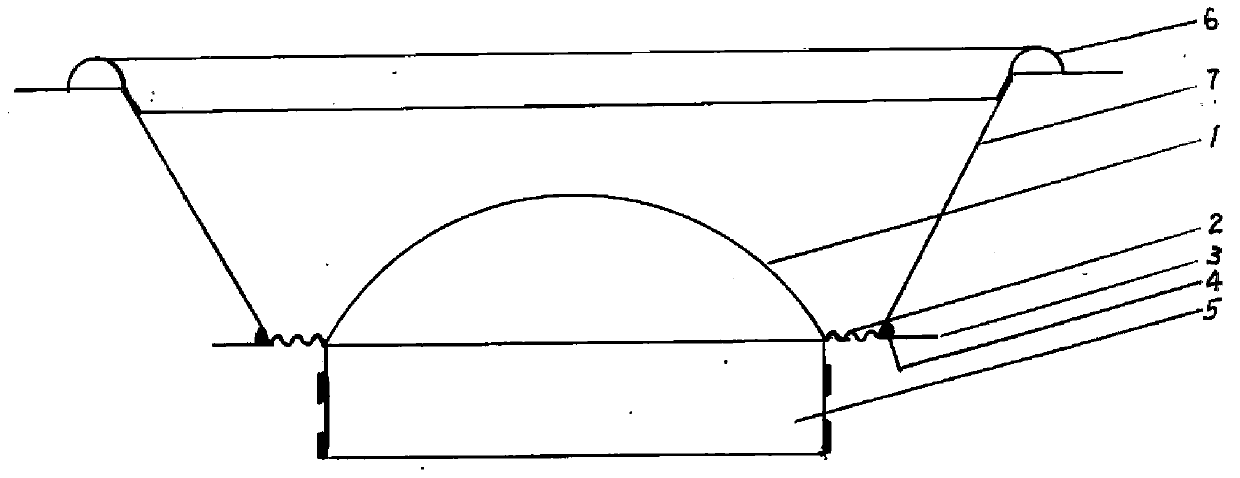

[0024] Two-in-one cone-shaped integrated diaphragm: see illustration figure 2 , On the road of scientific exploration, there will always be selection and utilization of existing conditions, especially ready-made items, and the premise that technical means can be realized is the process. In this example, the existing mid-bass diaphragm and treble diaphragm are selected, and they are combined into one, and a simple addition is made-connecting the two parts at the junction of the treble fixed ring and the main body of the mid-bass diaphragm. combined into a whole. The treble diaphragm is still the original treble diaphragm, and the mid-bass diaphragm is still the original mid-bass diaphragm. After being connected into one body, it becomes the integration of treble and mid-bass diaphragms with the same structure and the same work. The whole vibrating membrane——similar to Embodiment 1.

Embodiment 3

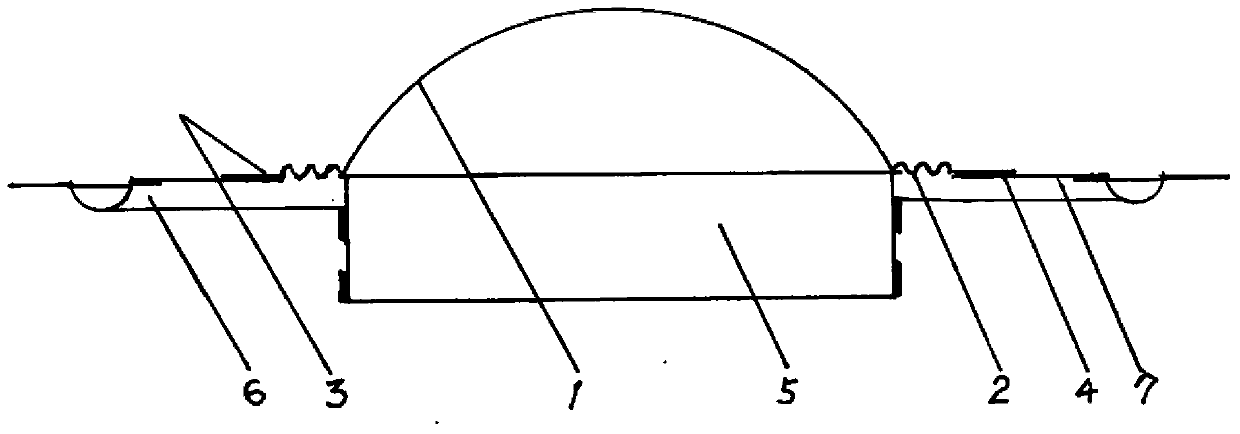

[0026] Two-in-one planar integrated diaphragm: see illustration image 3 , this embodiment is the same as the two-in-one conical integrated diaphragm, see schematic figure 2 , doing the same addition. The only difference is that the cone diaphragm is replaced by a flat diaphragm in the integrated monolithic diaphragm. The rest of the structure is the same. Compressed space for dynamic speakers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com