Grass surface adaptive laminated weeding machine for municipal landscape engineering

A self-adaptive, laminated technology, applied in the field of weeding, which can solve problems such as inability to trim up and down slopes, motor failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

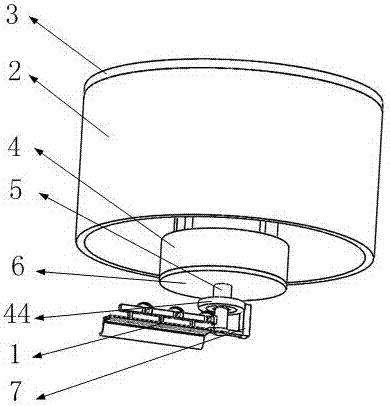

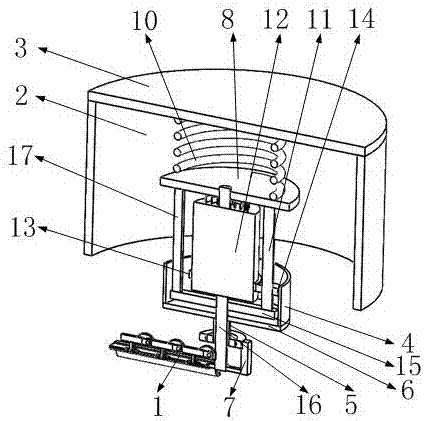

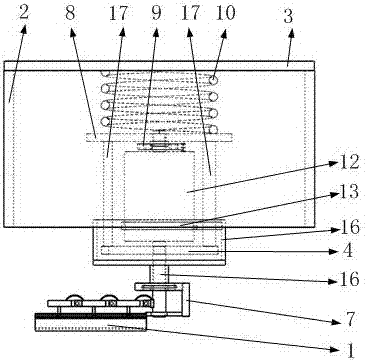

[0026] Such as figure 1 , 2 , 3, it includes the first cutting mechanism 1, the protective cover wall 2, the protective top cover 3, the ring gear 4, the ring shaft 5, the ring gear side wall 6, the second cutting mechanism 7, the support top cover 8, the scroll Spring 9, protection spring 10, second pole 11, motor 12, ring gear 13, first gear 14, chassis plate 15, motor shaft 16, first pole 17, fixed structure 20, bushing 22, shaft hole 23. Inner ring 26, collar 36, outer ring 44, among which figure 1 , 6 As shown, the protective cover wall 2 is installed at the lower end of the protective top cover 3, and the protective cover wall 2 and the protective cover 3 have the same diameter, as figure 2 As shown, one end of the protective spring 10 is installed on the lower side of the protective top cover 3, and the other end is installed on the upper side of the supporting top cover 8. A hole is arranged in the center of the supporting top cover 8, and a shaft sleeve 22 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com