Cyclone separator with material scraping device and conveying device

A technology of cyclone separator and conveying device, which is applied in the direction of swirl device, device whose axial direction can be reversed, engine sealing, etc., and can solve problems such as high moisture content, poor feeding, and material blocking , to achieve the effect of stable conveying capacity, preventing material blocking and unsmooth feeding, and high conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

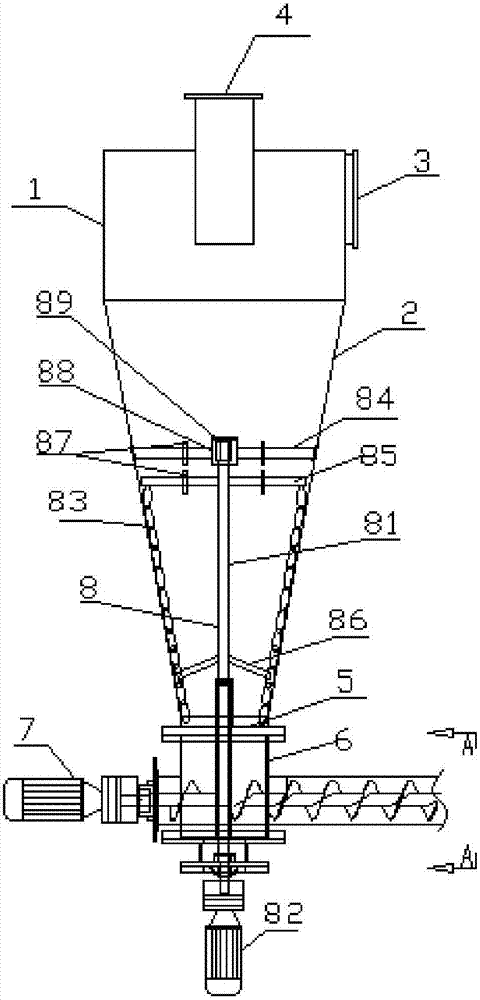

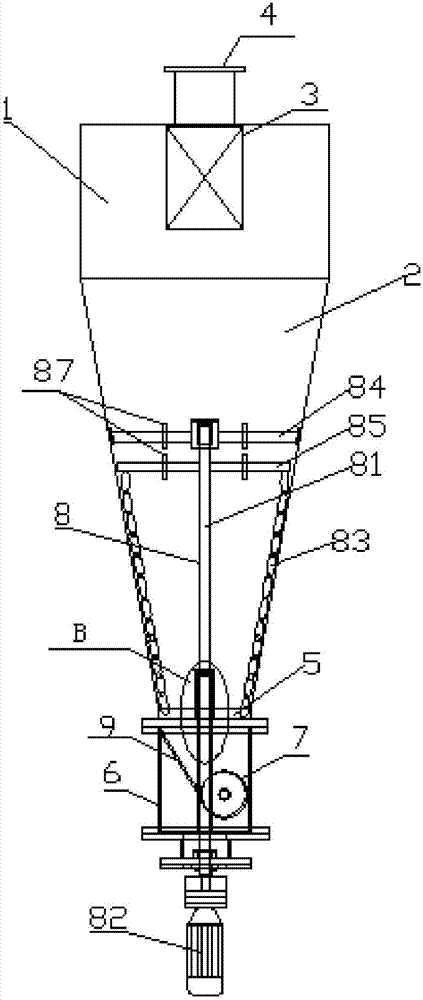

[0035] Such as figure 1 , Figure 3-Figure 5 As shown, a cyclone separator with a scraping and conveying device includes an integrally formed upper cylinder 1 and a lower cylinder 2;

[0036] The upper cylinder 1 is located above the lower cylinder 2, and the upper cylinder 1 is provided with an air inlet 3 and an air outlet 4;

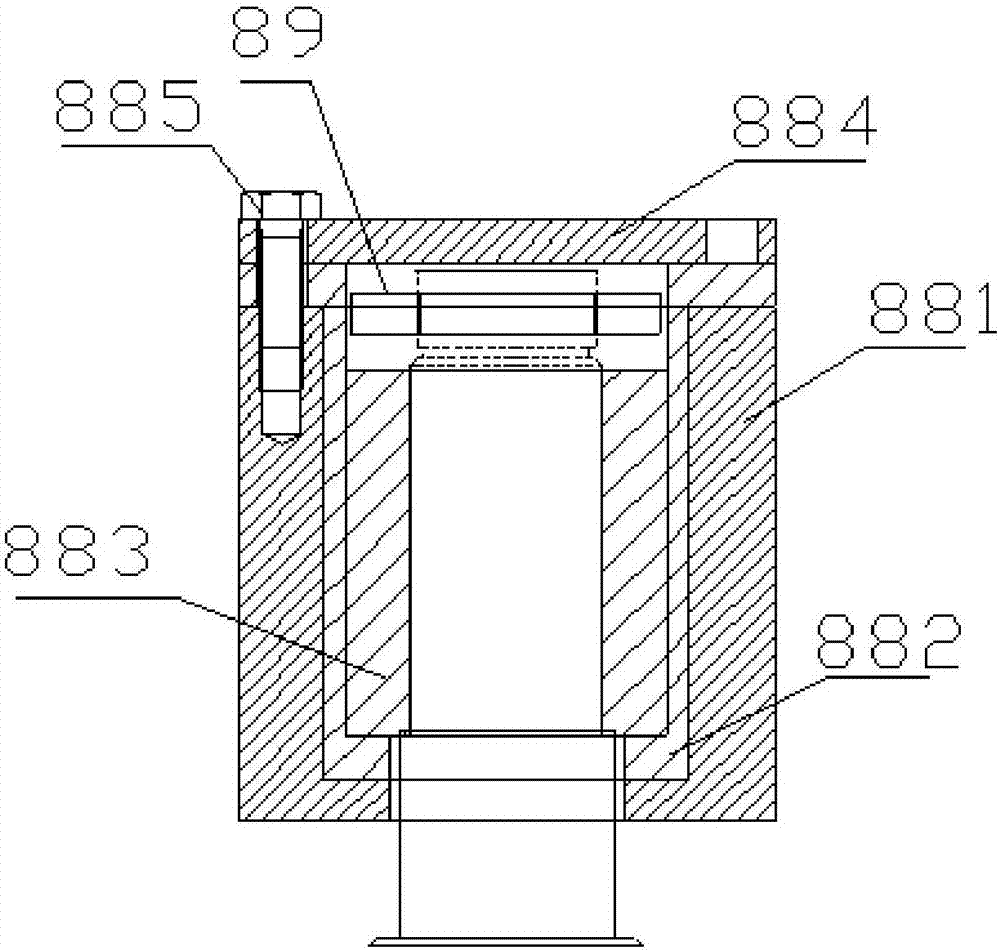

[0037] The bottom of the lower cylinder 2 is provided with a discharge port 5; the bottom of the lower cylinder 2 is provided with a coupling nipple 6 and a material conveying device 7; the upper end of the coupling nipple 6 is connected to the lower cylinder 2; the material The conveying device 7 is perpendicular to the connecting sub-joint 6, and one end thereof passes through the connecting sub-joint 6 horizontally; a scraping device 8 is provided inside the lower cylinder body 2, and the lower end of the scraping device 8 protrudes from the discharge port 5 and the The connecting sub-joint 6, the scraping device 8 and the material conveying devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com