Four-hole drilling fixture for end-face gear of transmission shaft

A technology of drive shaft and end face teeth, which is applied in the field of four-hole tooling for end face teeth of drive shafts, can solve problems such as poor positioning accuracy, and achieve the effects of solving safety problems, improving position accuracy, and speeding up progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

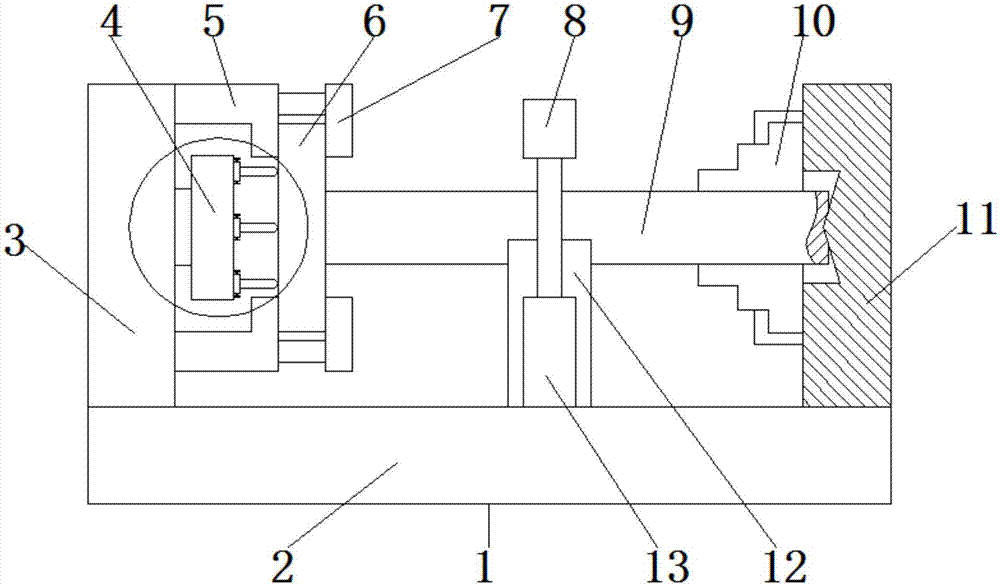

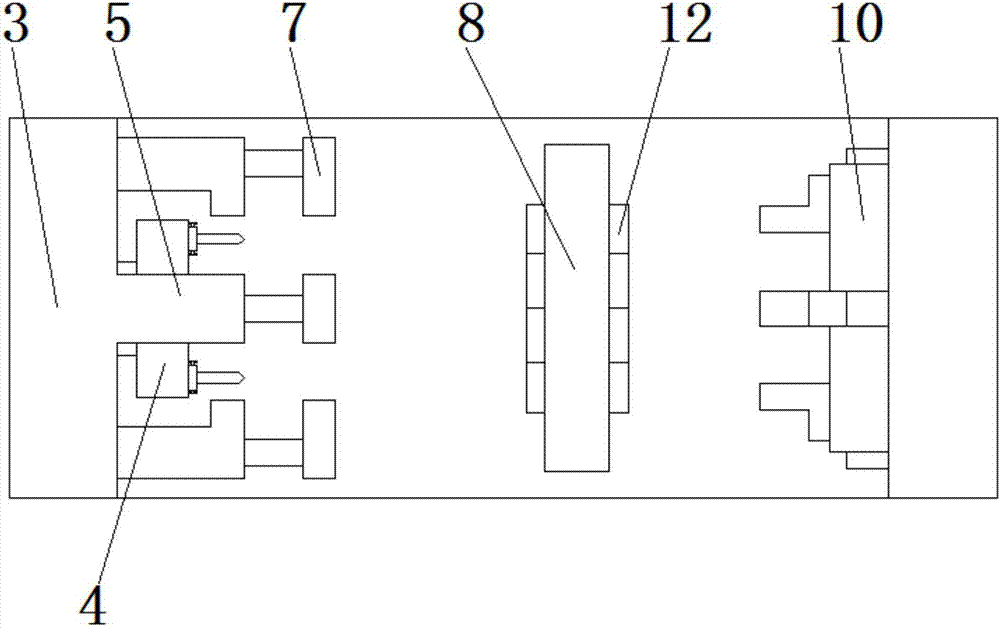

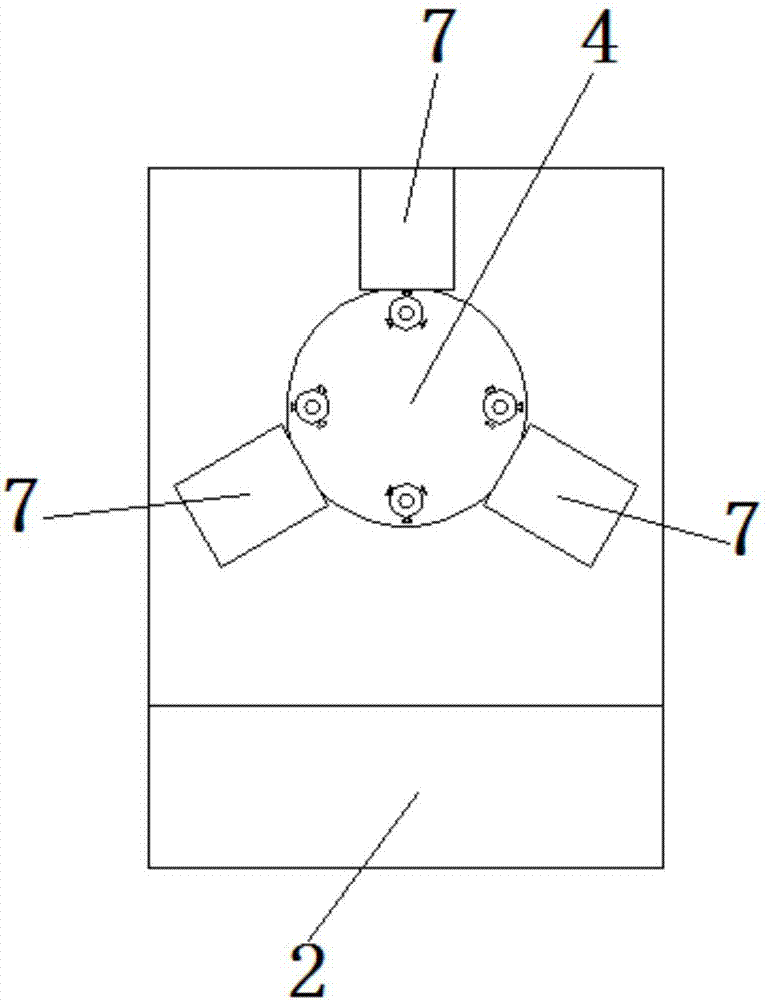

[0021] as attached figure 1 To attach Figure 4 Shown:

[0022] The present invention provides a technical solution: a transmission shaft end face gear drill four-hole tooling, including a device body 1, a base 2, a hydraulic box 3, a motor box 4, a clamping seat 5, an end gear 6, and a clamping block 7 , locking plate 8, transmission shaft 9, chuck 10, support plate 11, fixed support block 12, hydraulic seat 13, dismounting knob 14, motor shaft 15 and drill bit 16, device body 1 bottom is provided with base 2, and base 2 The right side of the top is connected to the support plate 11 by welding; the chuck 10 is connected to the left side of the support plate 11 by welding, and the transmission shaft 9 is installed inside the chuck 10; the left side of the chuck 10 is provided with front and rear Two hydraulic seats 13, and the bottom of the hydraulic seat 13 is connected to the top of the base 2 by welding; the top of the hydraulic seat 13 is connected with a locking plate 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com