Clip body manufacturing method of hairpin, clip body and hairpin composed of two clip bodies

A manufacturing method and clip body technology, which can be applied to curling or perming devices, hairdressing equipment, applications, etc., and can solve the problems of injury risk, unsatisfactory clip stability, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

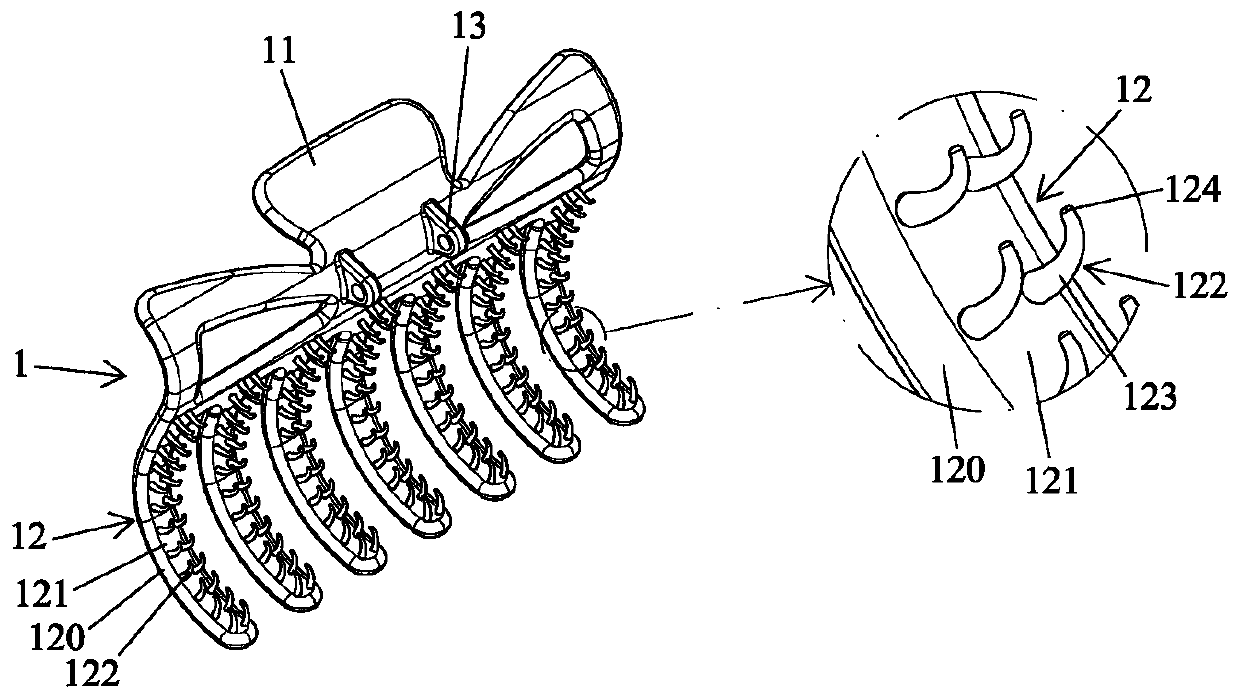

[0046] In the following embodiments, similar functional components of the present invention are represented by the same figure number, please refer to figure 1 In the first embodiment of the present invention, the clip body 1 of the hairpin is integrally molded from plastic, with a pressing portion 11 at one end and a clamping portion 12 at the other end, with jaws 120 arranged below the clamping portion 12, and the clip body 1 There is a pivot joint 13 on the inner side, and the clamping part 12 has an inner surface 121, and a plurality of tooth hooks 122 are arranged in a direction perpendicular to the corresponding inner surface 121. The connected straight part 123 is substantially straight, and the top end of the straight part 123 has a hook part 124 bent corresponding to the straight part 123 .

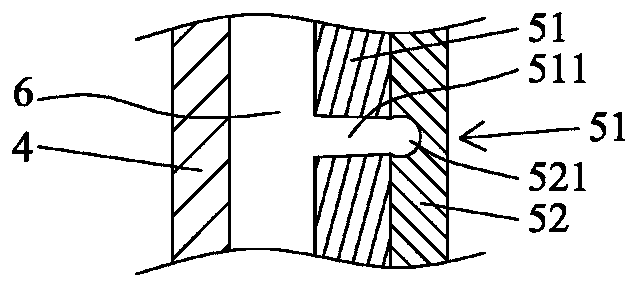

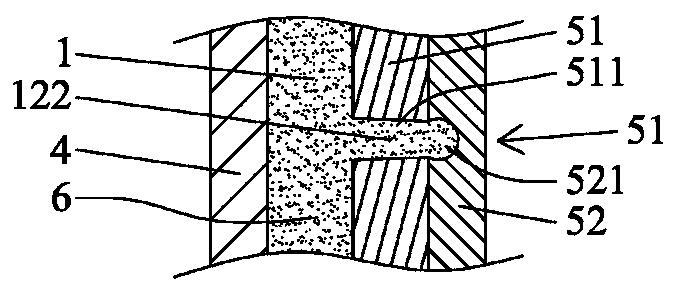

[0047] see figure 1 and Figure 2A to Figure 2E ,in Figure 2A to Figure 2E It mainly shows the position of the molded clip body 1 corresponding to the tooth hook 122. The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com