Plastic packaging bag clean film processing device

A processing device and packaging bag technology, applied in water supply devices, transportation and packaging, thin material handling, etc., can solve the problems of film deformation, small thickness, poor thermal stability, etc., and achieve the effect of smooth unwinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

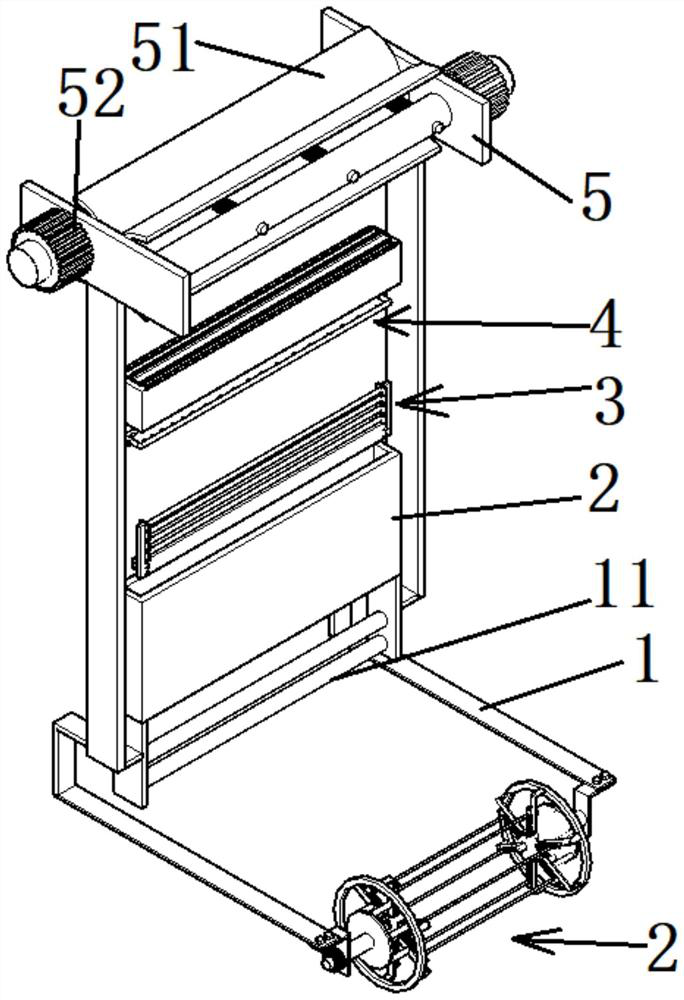

[0045] like Figure 1-8 As shown, a clean film processing device for plastic packaging bags includes bottom frame rods 1 arranged at intervals in the front and rear, and an elastic feeding mechanism 2 is assembled and connected between the outer ends of the bottom frame rods 1;

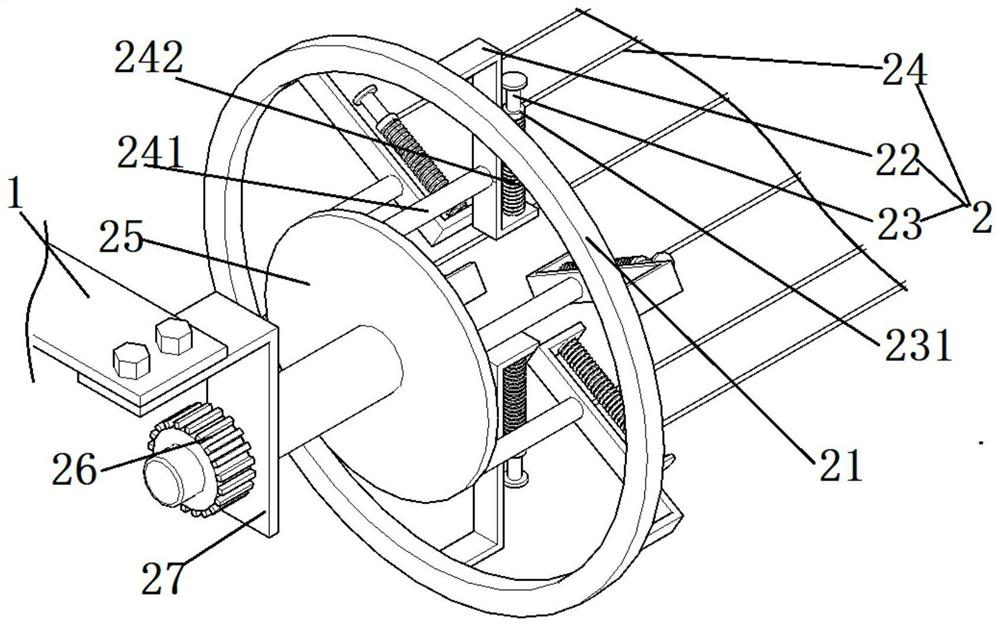

[0046] Specifically, the elastic feeding mechanism 2 realizes the winding of the film for winding. The specific structure of the elastic feeding mechanism 2 is as follows:

[0047]The elastic feeding mechanism 2 includes folded end frames 27 (L-shaped steel plates) arranged at intervals in the front and rear, and the folded end frames 27 are fixedly assembled on the bottom of the bottom frame rod 1 . Specifically, it is assembled by bolts. The folded end frame 27 is provided with end seat portions, and elastic feeding components are rotatably connected between the end seat portions.

[0048] The specific structure of the elastic feeding part is as follows:

[0049] The elastic feeding component in...

Embodiment 2

[0055] like Figure 1-8 As shown, in this embodiment, on the basis of the structure of Embodiment 1, the inner end of the bottom frame rod 1 is fixedly connected with the longitudinal frame 6 facing upward.

[0056] A clean film sterilization mechanism is assembled and connected between the lower ends of the longitudinal frame 6; specifically, the clean film sterilization mechanism includes a longitudinally arranged sterilization box 2, and the bottom and bottom of the sterilization box 2 are provided with material holes, and the longitudinal frame 6 A bottom vertical plate is fixedly connected with the bottom of the bottom vertical plate, and a limit material rod 11 arranged at an upper and lower interval is fixedly connected between the bottom vertical plates. After the unrolled film is staggered and interspersed between the limit material rods 11, it enters the sterilization box 2 for longitudinal transmission, and is sterilized during the longitudinal transmission.

[005...

Embodiment 3

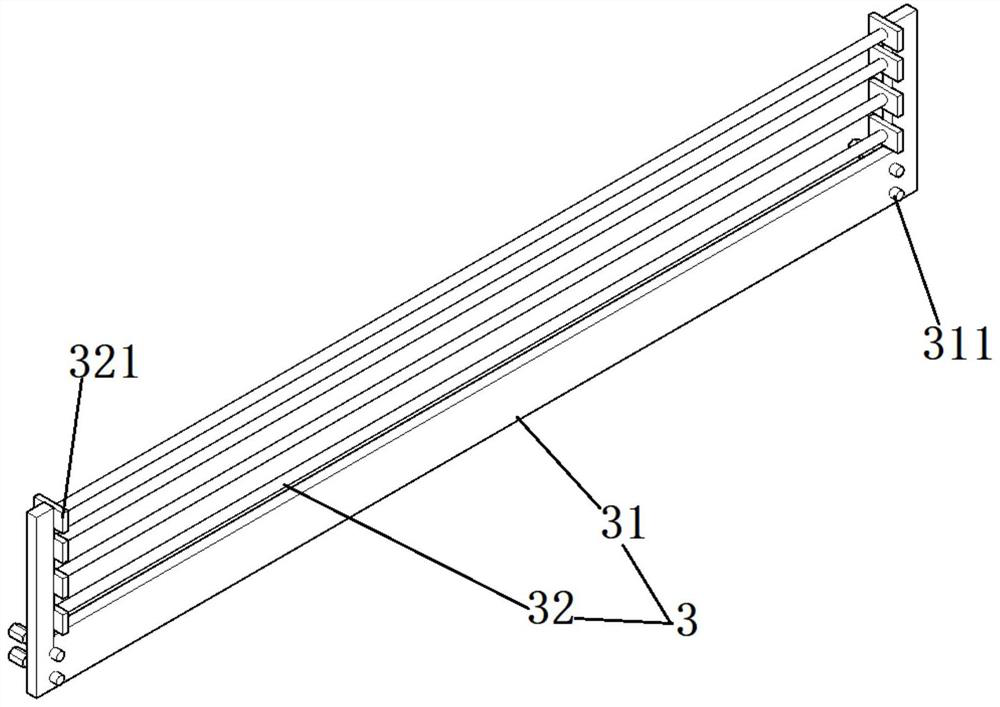

[0062] In this embodiment, on the basis of the structure of Embodiment 2, in order to realize the vertical pulling and conveying of the film, specifically, because the alcohol disinfectant is attached to the film, its lubricity is increased, and the transmission and conveying device cannot be smoothly conveyed. The conveying process Slip is prone to occur in the film, resulting in film breakage.

[0063] The specific structure of the arc plate pulling assembly is as follows:

[0064] The arc-shaped plate pulling assembly includes a horizontal base plate 5 that is fixedly connected to the top of the longitudinal frame 6, respectively, and two drive rollers 53 spaced left and right are rotatably connected to the horizontal base plate 5, and the drive rollers 53 are assembled and connected respectively. The cooperating bearing plate 51 (the heart-shaped angle of the bearing plate 51 is 180 degrees), the bearing plate 51 is assembled and connected to the driving roller 53 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com