Pipeline internal field manufacturing and detection tool

A technology for testing tooling and pipelines, applied in transportation and packaging, ship components, ships, etc., can solve problems such as speeding up shipbuilding speed and cycle, difficult quality assurance, and large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

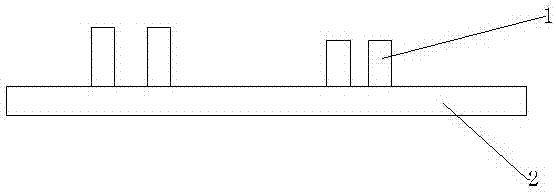

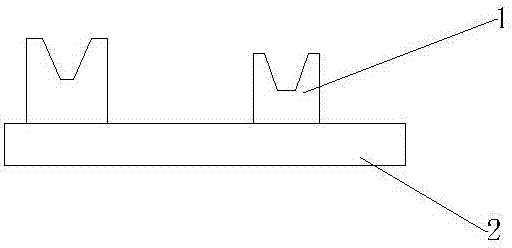

[0009] Such as figure 1 , figure 2 As shown, the pipeline infield production and testing tooling includes a production platform 2 and a plurality of V-shaped wedge blocks 1. The V-shaped wedge blocks 1 are arranged on the production platform 2. The V-shaped wedge blocks 1 are in groups of two. The shape and size of the V-shaped opening of the V-shaped wedge 1 can be different, but the shape and size of the V-shaped opening of the V-shaped wedge 1 in the same group should be consistent, and the axes of the V-shaped openings of the V-shaped wedge 1 in the same group should be consistent. , which is the same axis, when the pipeline is placed in the two V-shaped openings, the axis of the pipeline is horizontal, the production platform 2 is made of steel plate, and the production platform 2 is provided with horizontal and vertical scale lines, between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com