Electric control locking mechanism for tail door

A gate and electric cylinder technology, applied in the field of vehicles, can solve problems such as the inability to meet the requirements of full-automatic electronic control of the structure of the flip-down gate, achieve strong self-adjustment and self-adaptation capabilities, significantly improve locking performance, and facilitate maintenance. replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings, but not as a limitation of the present invention.

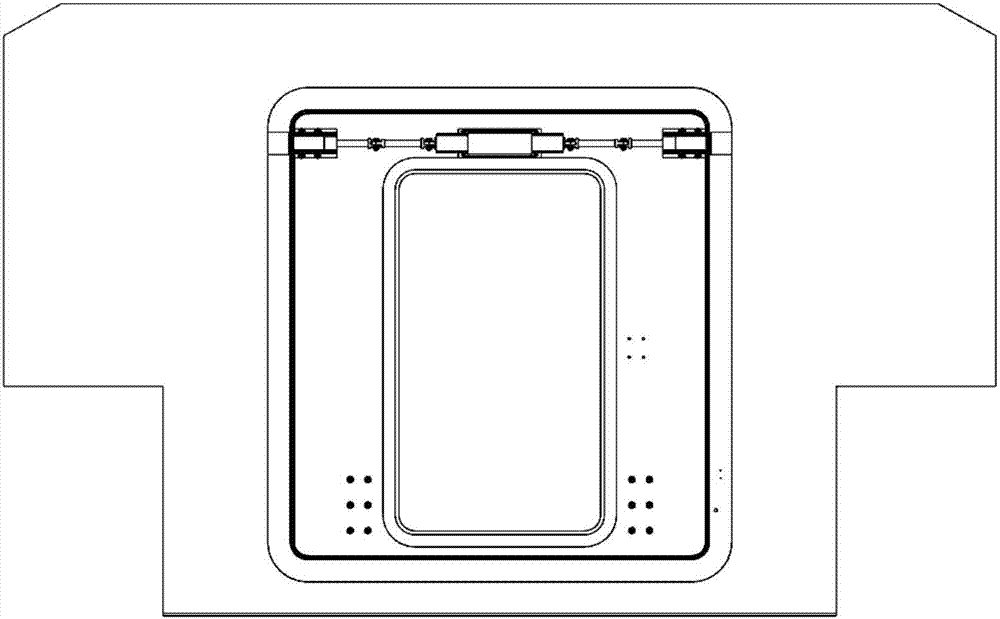

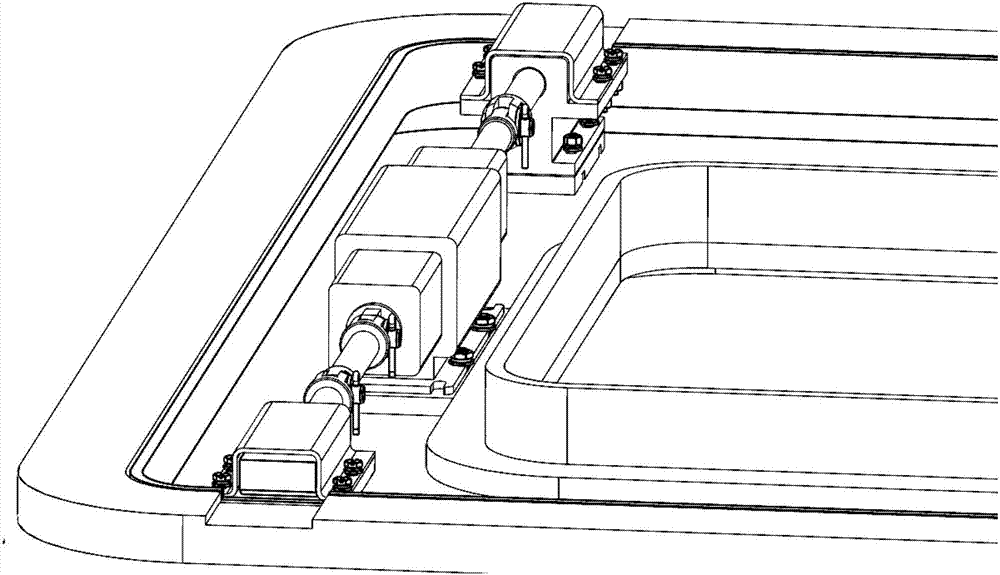

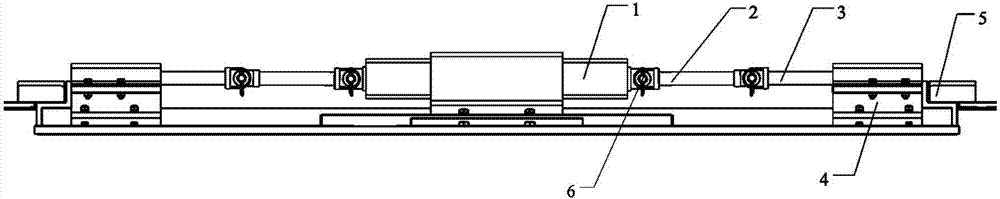

[0028] Such as diagram 2-1 , Figure 2-2 , Figure 3-1 , Figure 3-2 As shown, the locking mechanism of the present invention is installed on the door body, and the entire mechanism structure is divided into a front locking rod structure, a rear locking rod structure and a lock seat structure:

[0029] Front lock lever structure: the two-way electric cylinder 1 is reversely fixed on the door panel through the bolt 8, and the output end of one end of the two-way electric cylinder 1 is hinged to the front lock lever 2 through the first pin shaft.

[0030] Rear lock bar structure: the front lock bar 2 is hinged with the rear lock bar 3 through the second pin shaft, and the tail end of the rear lock bar 3 passes through the opening of the dead bolt bracket 4 and is threadedly connected with the dead bolt 9 to form a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com