Preheating system of engine, control method thereof and vehicle

A control method and engine technology, which are applied in the directions of engine starting, engine cooling, engine components, etc., can solve the problems of high application cost, complex preheating system structure, slow response speed, etc., and achieve low production cost, clear layout, Responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0030] First, the present invention will be described in detail with reference to the drawings and examples.

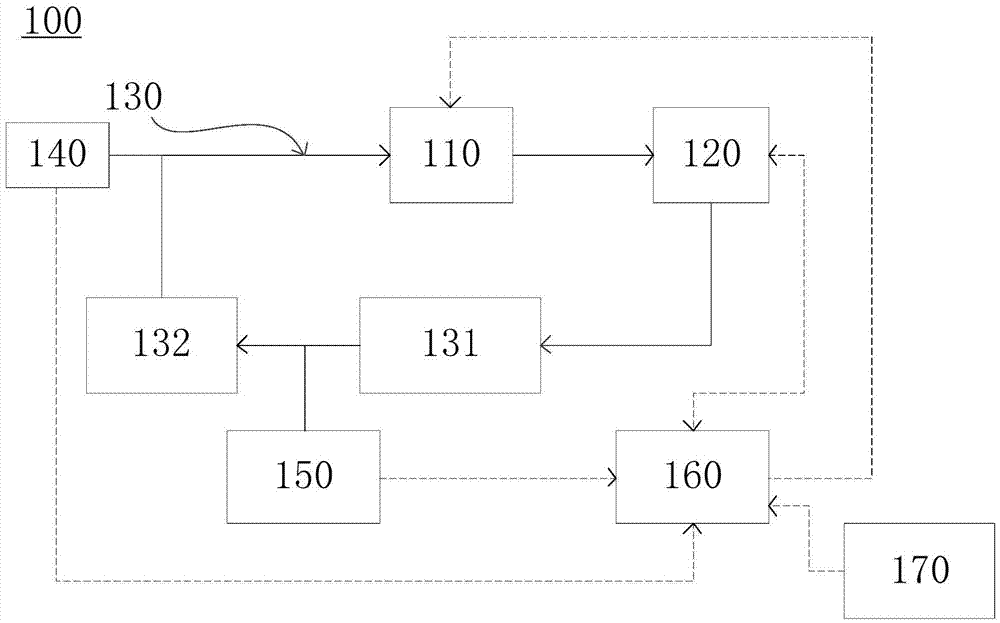

[0031] When the main valve of the thermostat is opened, the coolant flows in the large circulation loop to quickly reduce the temperature of the engine; when the main valve of the thermostat is closed, the coolant flows in the small circulation loop 130, at this time the coolant Does not flow into the tank.

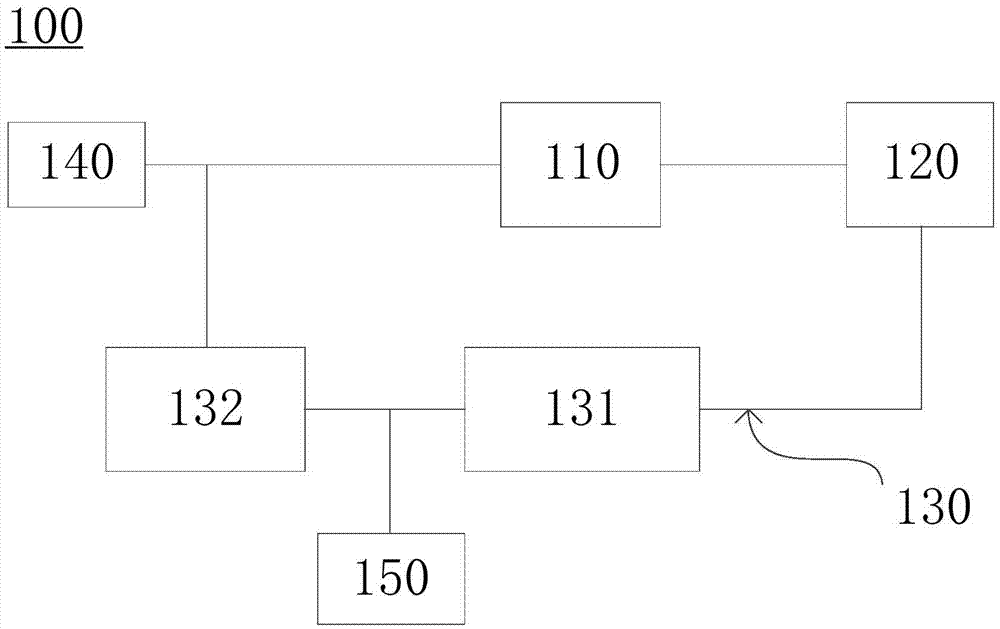

[0032] Such as Figure 1-Figure 2 As shown, the engine preheating system 100 includes a small circulation loop 130 , a heating unit 110 , a water pump 120 and a flow detection unit 140 .

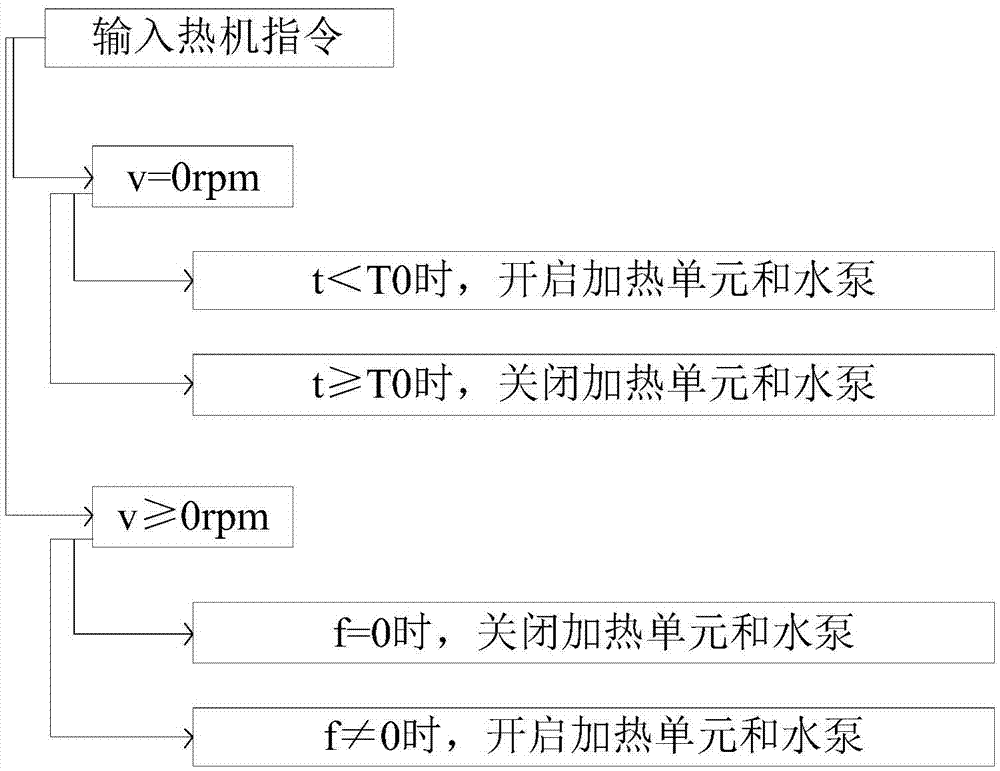

[0033] Wherein, the heating unit 110 is connected in series in the small circulation loop 130, the heating unit 110 is used to heat the coolant in the small circulation loop 130, the water pump 120 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com