Pipeline connector device

A technology for connecting heads and pipelines, which is applied in the field of pipeline connecting devices, and can solve problems such as large safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

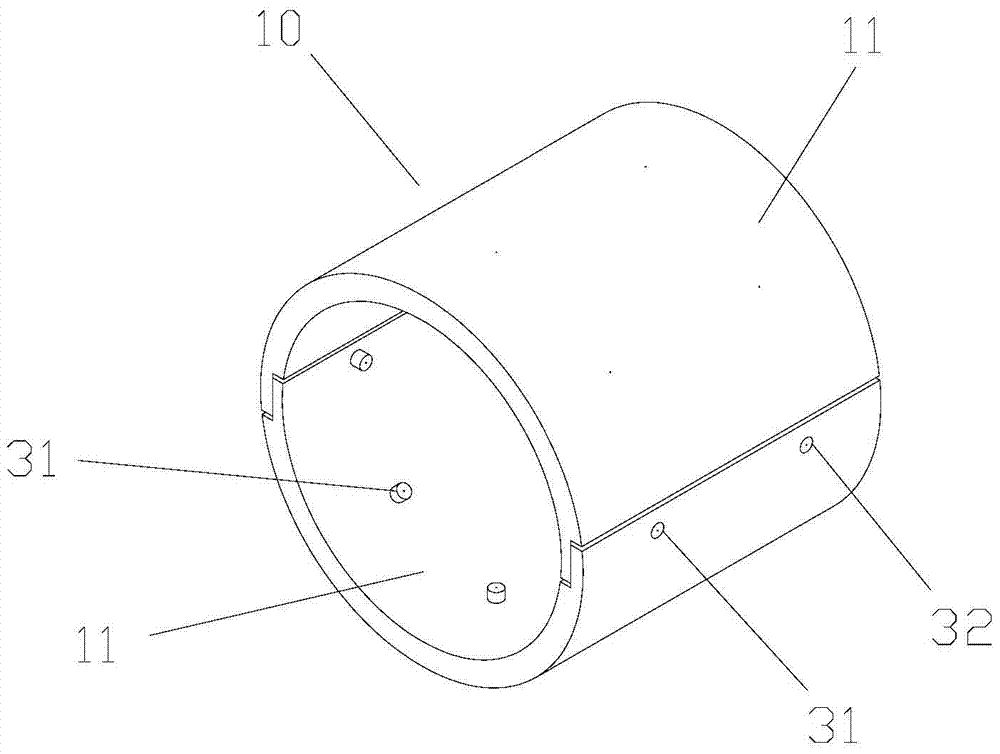

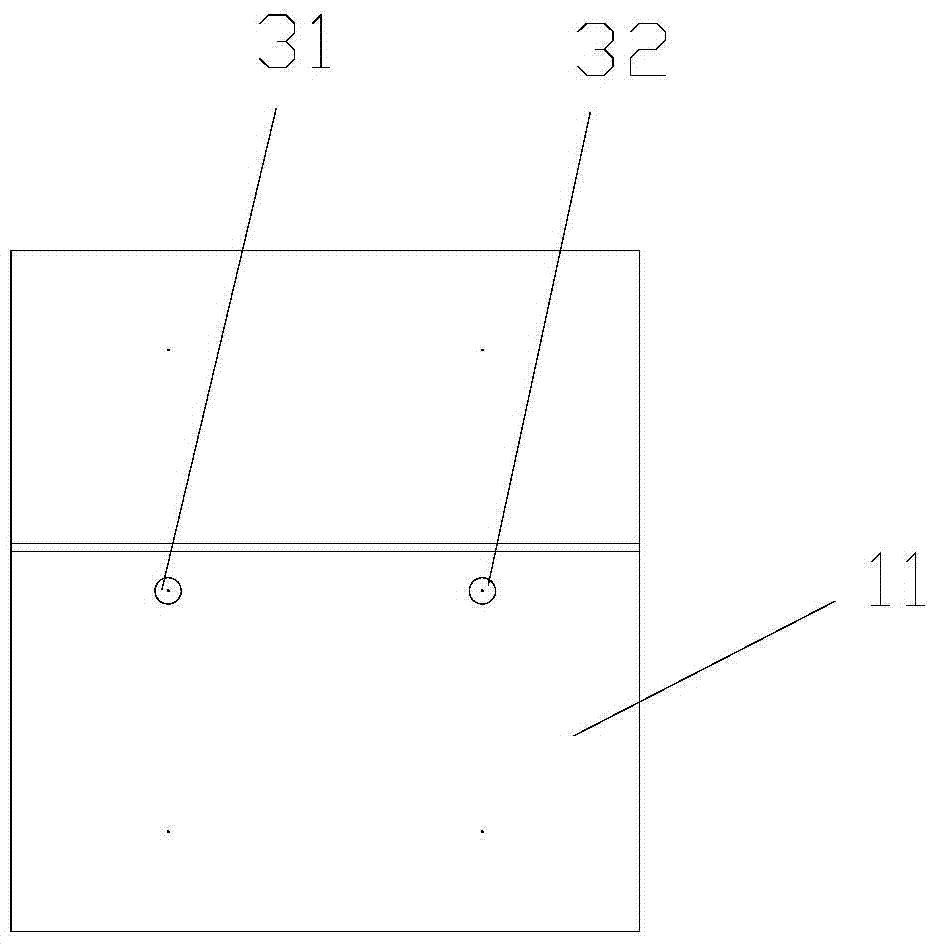

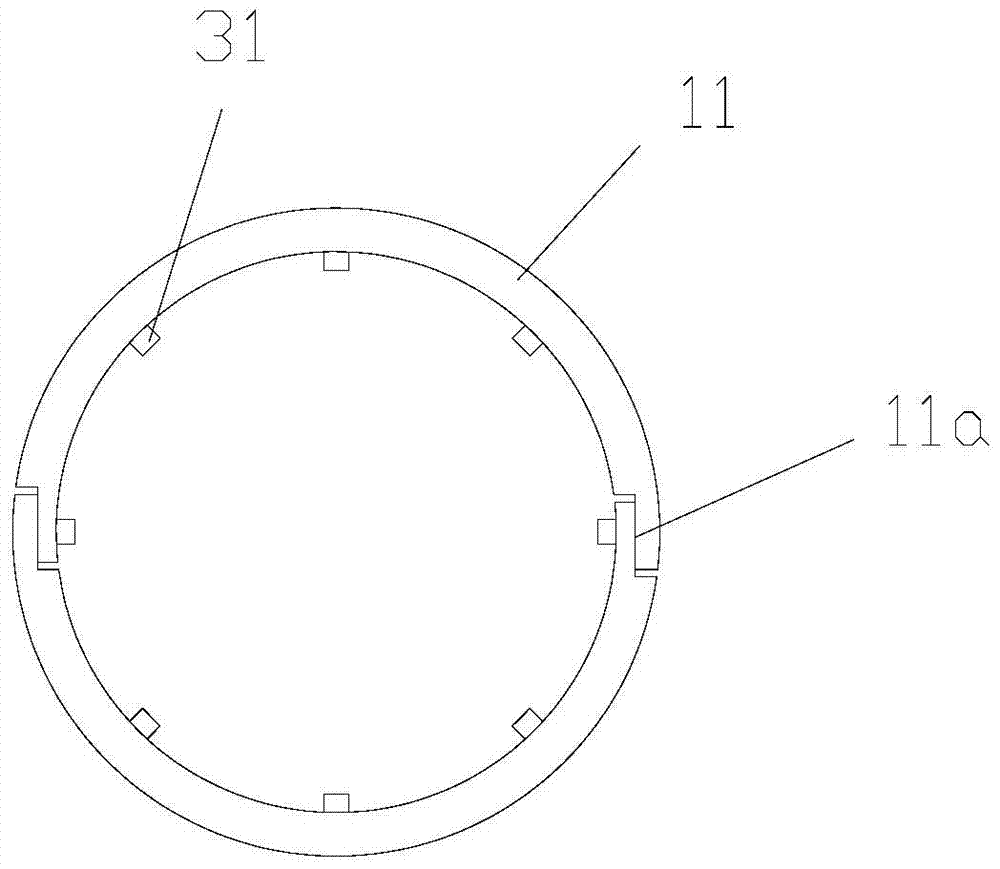

[0034] This embodiment provides a pipeline connector device, please refer to Figure 1 to Figure 9 , the pipeline joint device includes: a fixed slip 10, the fixed slip 10 is composed of a plurality of tiles 11 spliced sequentially along its circumference, and each tile 11 is wrapped in the first pipe body 21 and the second pipe to be connected. On the pipe body 22; wherein, at least one tile plate 11 is provided with a first positioning member 31 for being inserted into the first positioning hole 211 of the first pipe body 21 for positioning, and at least one tile plate 11 is provided with a first positioning member 31 for inserting The second positioning member 32 is disposed in the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com