The Construction Method of Leakage Prediction and Treatment of Underground Diaphragm Wall

A technology of underground diaphragm wall and construction method, applied in sheet pile wall, foundation structure engineering, by detecting the appearance of fluid at leakage point, etc., can solve problems such as the safety risk of water seepage, achieve advance treatment and reduce the probability of water seepage , Improve the effect of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

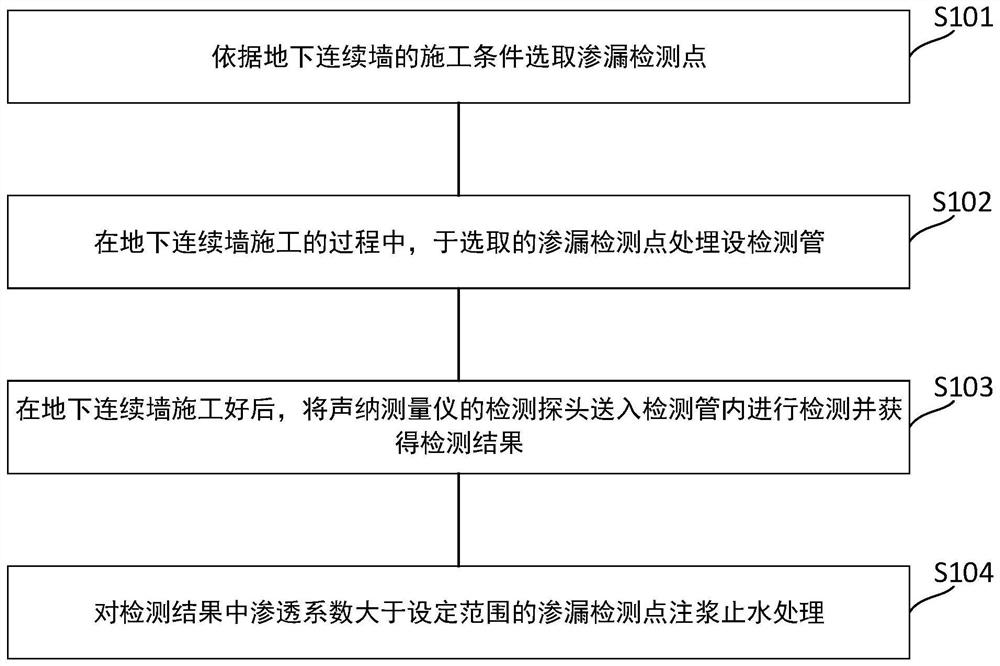

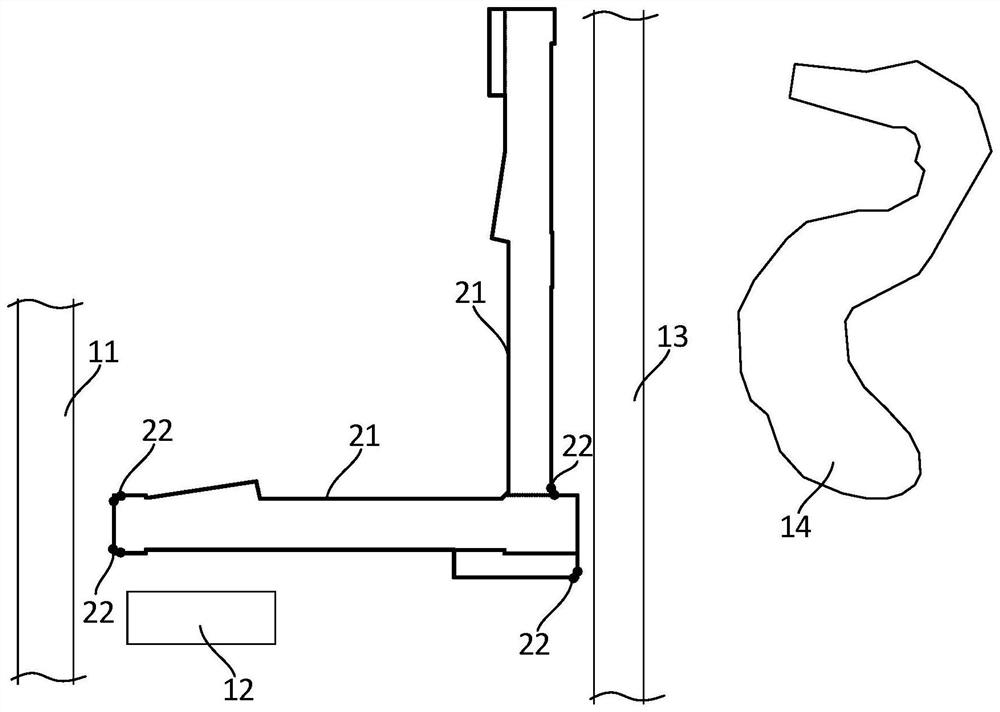

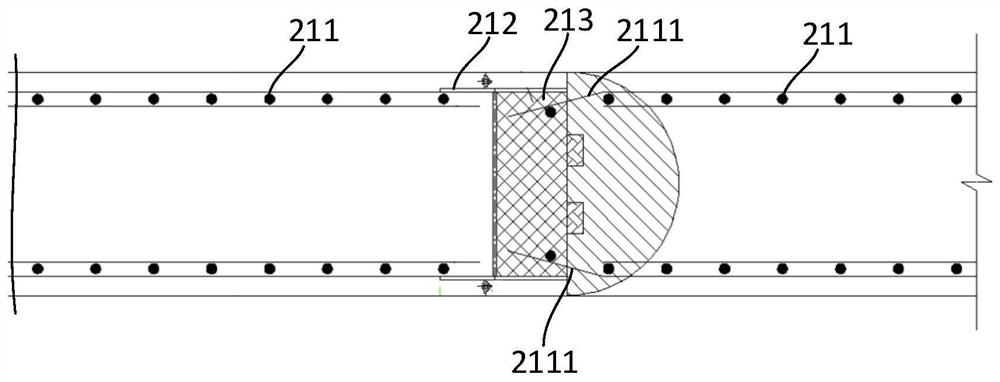

[0039] refer to figure 1 , the present invention provides a construction method for the prediction and treatment of underground diaphragm wall leakage, which is used to detect whether there is leakage in the underground diaphragm wall in advance, and take timely measures when there is water seepage, so as to avoid water gushing and sand gushing in foundation pit excavation risk. By analyzing the structural form of the underground diaphragm wall, the geological conditions and the influence of surrounding buildings, the present invention determines in advance the position where sonar detection is most needed, and reduces the detection cost; the pre-embedded detection tube is simple and convenient, and the quality is highly controllable; Detect groundwater flow conditions, and the test results are highly reliable; for locations where the seepage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com