Tile grout, and construction method thereof

A construction method and technology of caulking agent, applied in the field of caulking agent, can solve the problems of poor wear resistance, high cost performance, low cost, etc., and achieve the effect of solving water seepage, good wear resistance and adhesion, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

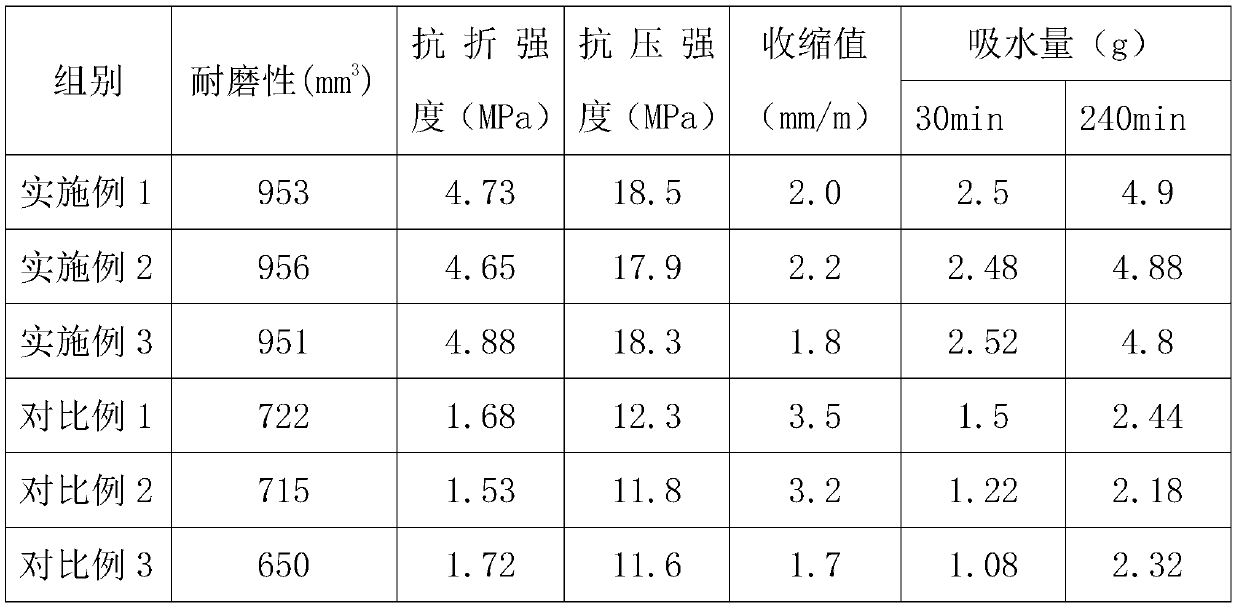

Examples

Embodiment 1

[0018] A tile grout, comprising the following raw materials by weight: including the following raw materials by weight: 350 parts of cement, 454.5 parts of quartz sand, 150 parts of heavy calcium, 25 parts of redispersible latex powder, 0.3 parts of methyl cellulose 10 parts of bentonite, 10 parts of slaked lime, and 0.3 parts of superplasticizer.

[0019] The water reducer is MF10 water reducer

[0020] In the present embodiment, the preparation method of the ceramic tile grout, the steps are as follows:

[0021] S1. Carry out 24 hours after the tile laying is completed, first clean the tile gap, remove the dust, tile adhesive and oil stains on the tile surface;

[0022] S2. Take the ceramic tile grout, put it into the mixer, then add water to the mixer and stir, the speed of the mixer is 1500r / min, stir until there is no blocky solid in the mixer, then turn off the mixer, let it stand for 5min, and set aside;

[0023] S3. Use a rubber caulking knife to fill the well-mixed ...

Embodiment 2

[0026] A tile grouting agent, comprising the following raw materials in parts by weight: 200 parts of cement, 400 parts of quartz sand, 100 parts of heavy calcium, 10 parts of redispersible latex powder, 0.1 part of methyl cellulose, 1 part of bentonite, 5 parts of slaked lime part, 0.1 part of superplasticizer.

[0027] The water reducer is MF10 water reducer

[0028] In the present embodiment, the preparation method of the ceramic tile grout, the steps are as follows:

[0029] S1. Carry out 24 hours after the tile laying is completed, first clean the tile gap, remove the dust, tile adhesive and oil stains on the tile surface;

[0030] S2. Take the ceramic tile grout, put it into the mixer, then add water to the mixer and stir, the speed of the mixer is 1500r / min, stir until there is no blocky solid in the mixer, then turn off the mixer, let it stand for 5min, and set aside;

[0031] S3. Use a rubber caulking knife to fill the well-mixed caulking agent into the gap between ...

Embodiment 3

[0034] A ceramic tile joint sealant, comprising the following raw materials in parts by weight: 400 parts of cement, 500 parts of quartz sand, 255 parts of heavy calcium, 50 parts of redispersible latex powder, 0.6 part of methyl cellulose, 15 parts of bentonite, and 15 parts of slaked lime 1 part, 1 part of water reducer.

[0035] The water reducer is MF10 water reducer

[0036] In the present embodiment, the preparation method of the ceramic tile grout, the steps are as follows:

[0037] S1. Carry out 24 hours after the tile laying is completed, first clean the tile gap, remove the dust, tile adhesive and oil stains on the tile surface;

[0038] S2. Take the ceramic tile grout, put it into the mixer, then add water to the mixer and stir, the speed of the mixer is 1000r / min, stir until there is no blocky solid in the mixer, then turn off the mixer, let it stand for 5min, and set aside;

[0039] S3. Use a rubber caulking knife to fill the well-mixed caulking agent into the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com