Sleeve for flue installation and manufacturing method thereof

A flue and bushing technology, which is applied in the field preparation of building components, vertical pipes, building structures, etc., can solve problems such as difficulty in guaranteeing construction quality, neglect of flue ducts, and cumbersome hanging process, etc. Achieve the effect of firm and reliable fixing effect, simple structure, and easy manufacture and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

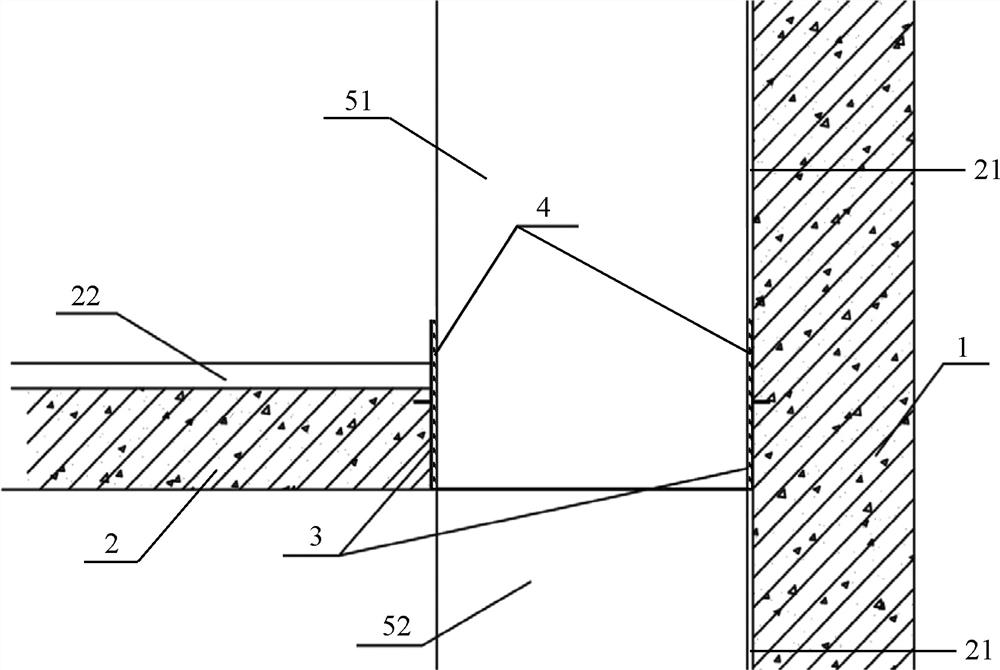

[0027] A sleeve for flue installation, including shear wall 1, floor panel 2, sleeve 3, foam 4, upper flue 51 and smoking 52, such as Figure 1 ~ 5 As shown, the specific structure is:

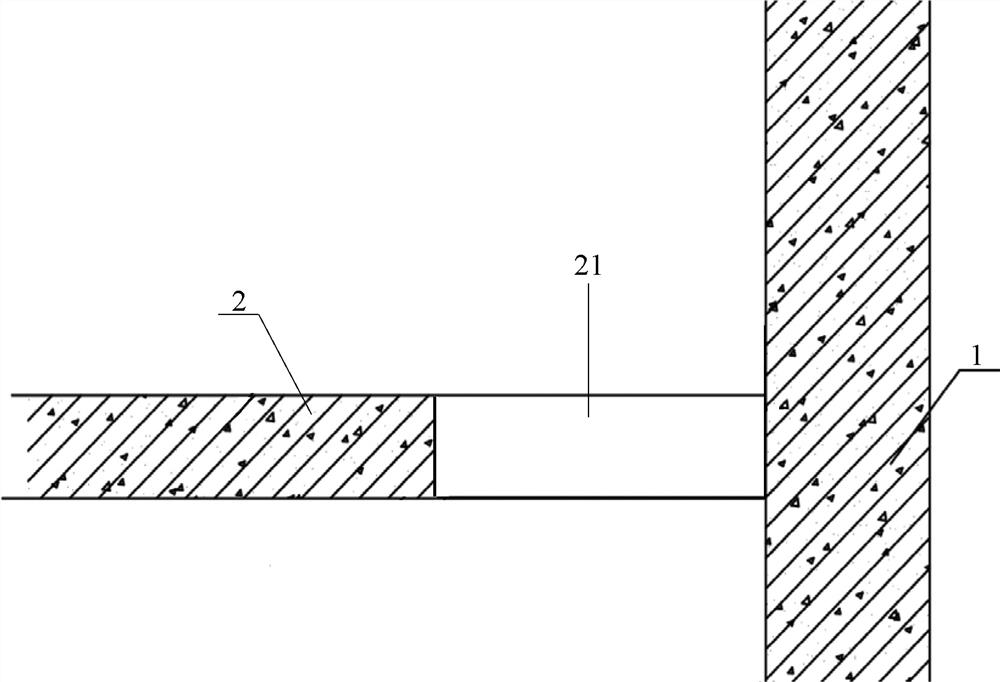

[0028] The shear wall is provided vertically, the floor 2 level is arranged, and the two ends of the floor 2 are arranged on a shear wall 1, and one end of the floor 2 is provided with a flue hole 21;

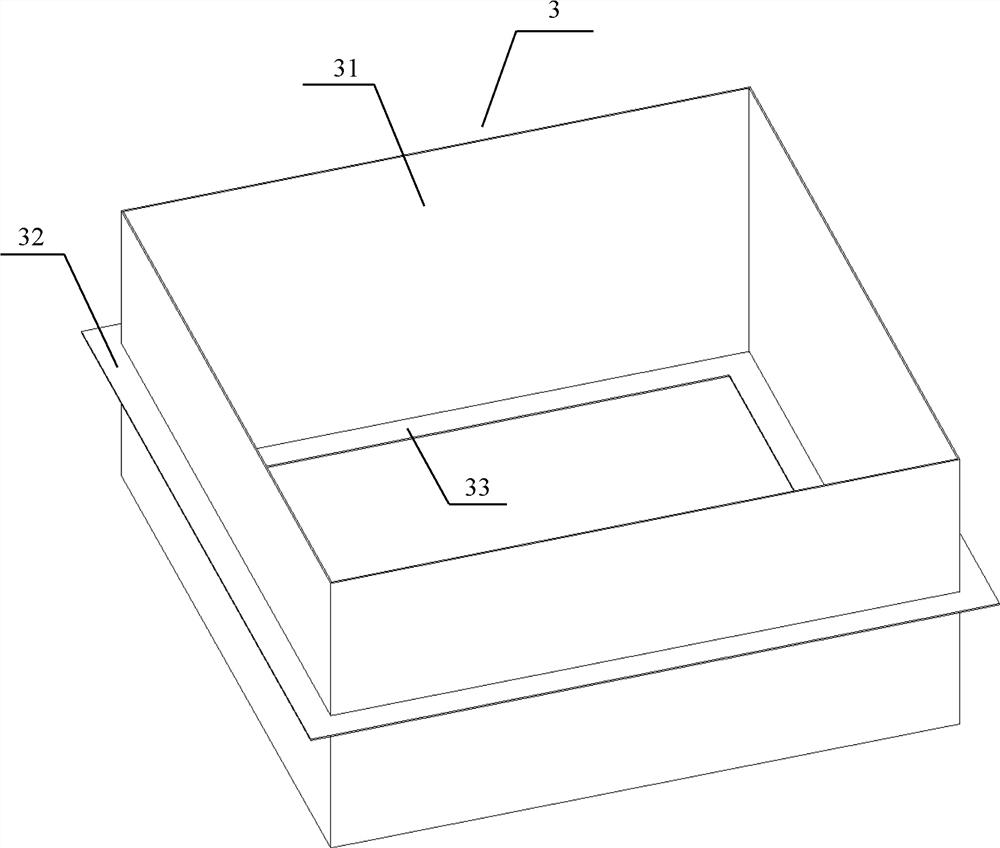

[0029] Coil 3 Figure 3 ~ 5 As shown: The sleeve 3 includes a tube wall 31, an outer ring baffle 32, and a bottom ring baffle 33, and the tube wall 31 is a central tubular shape, and the outer ring baffle 32 is closed, and the outer surface of the tube wall 31 The middle, the bottom ring barrier 33 is an annular, and the outer edge of the bottom ring block 33 is fixed to the edge of the bottom end ring 33 on the edge of the tube wall 31 on the edge of the bottom end surface of the tube wall 31;

[0030] The sleeve 3 is set outside the flue hole 21, and the partial tube wall 31 and the portion of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com