Restroom water-seepage-preventing construction structure and construction method thereof

A construction method and anti-seepage technology, applied to building components, building structures, building insulation materials, etc., to achieve the effect of solving the hidden danger of water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

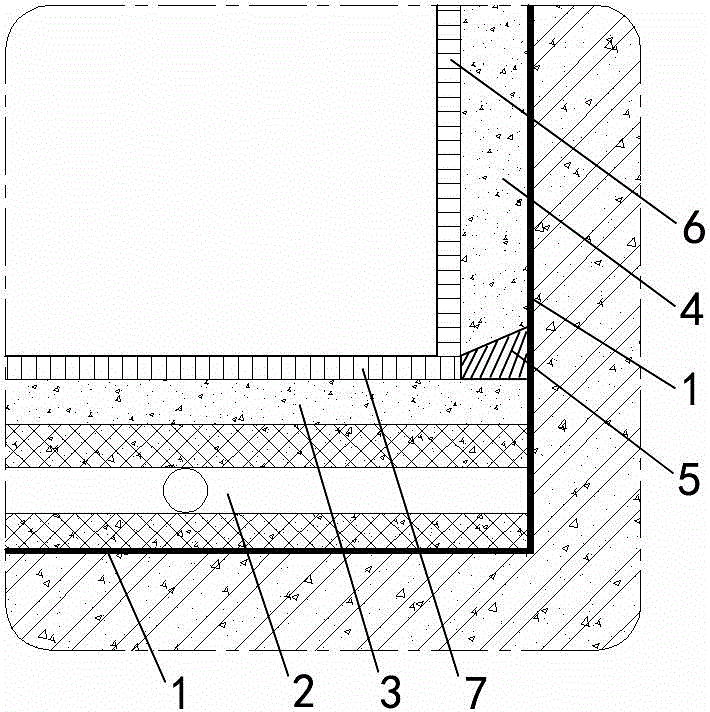

[0021] like figure 1 Shown, a toilet anti-seepage construction structure, it includes waterproof layer 1, geothermal structure layer 2, ground cement mortar leveling layer 3, floor tile 7, wall cement layer 4, anti-seepage strip 5, wall tile 6.

[0022] A waterproof layer 1 is arranged on the building structure, and the waterproof layer 1 includes a ground waterproof layer part and a wall waterproof layer part, and the ground waterproof layer part and the wall waterproof layer part are a complete waterproof layer as a whole. A geothermal structure layer 2 , a ground cement mortar leveling layer 3 , and floor tiles 7 are sequentially arranged above the ground waterproof layer. A wall cement layer 4 and wall bricks 6 are sequentially arranged on the outside of the wall waterproof layer. An anti-seepage water strip 5 extending along the extension direction of the wall corner is arranged between the floor tile 7 and the waterproof layer of the wall. , the position where the slop...

Embodiment 2

[0025] A construction method for anti-seepage water in toilets. When the construction of the floor tiles is completed, plain cement paste is used to plaster the slope surface between the floor tiles 7 and the original wall surface to manufacture an anti-seepage water strip 5 extending along the extension direction of the wall corner; and then Carry out the laying of wall tiles 6.

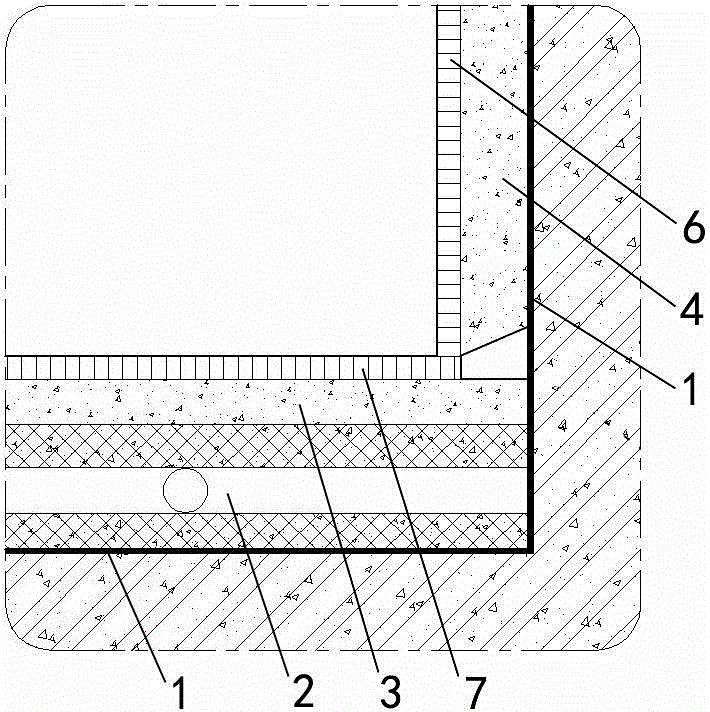

[0026] The anti-seepage strip 5 is a plain cement paste structural strip. The slope angle of the upper end surface of the anti-seepage water strip 5 is 30 degrees. The section of the anti-seepage strip 5 is a right-angled trapezoid.

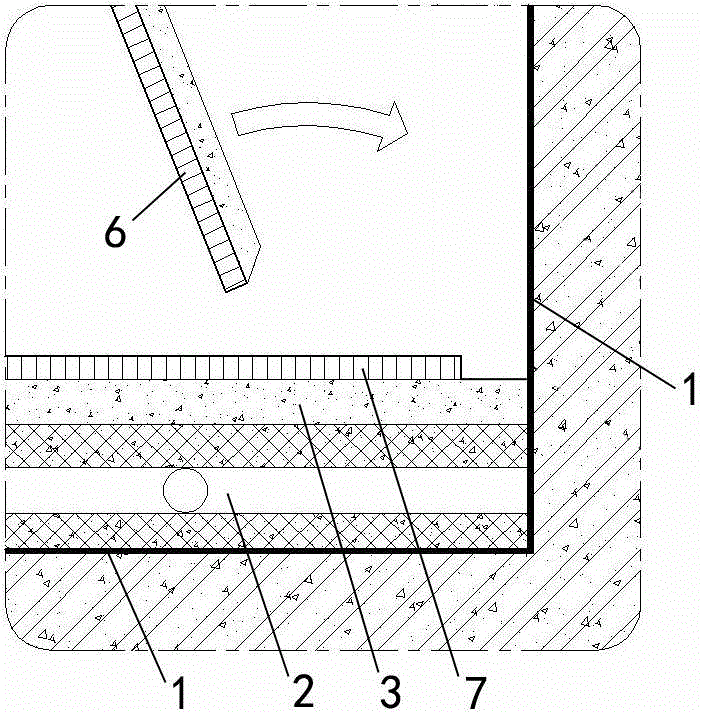

[0027] like figure 2 , image 3 As shown, in the traditional construction process, an invisible water channel will be formed between the wall tile 6 and the floor tile 7 (refer to image 3 The corner of the wall), this embodiment increases the 30-degree slope treatment of the wall corner plastering after floor tile construction, which effectively prevents the form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com