Basement waterproof foundation pit structure and construction method thereof

A construction method and technology for basements, which are applied in infrastructure engineering, protection devices, buildings, etc., can solve the problems of easy formation of weak parts in diaphragm wall joints, difficult to guarantee the pouring quality, and large depth of diaphragm walls, etc., to achieve easy quality control and construction. The effect of easy quality and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

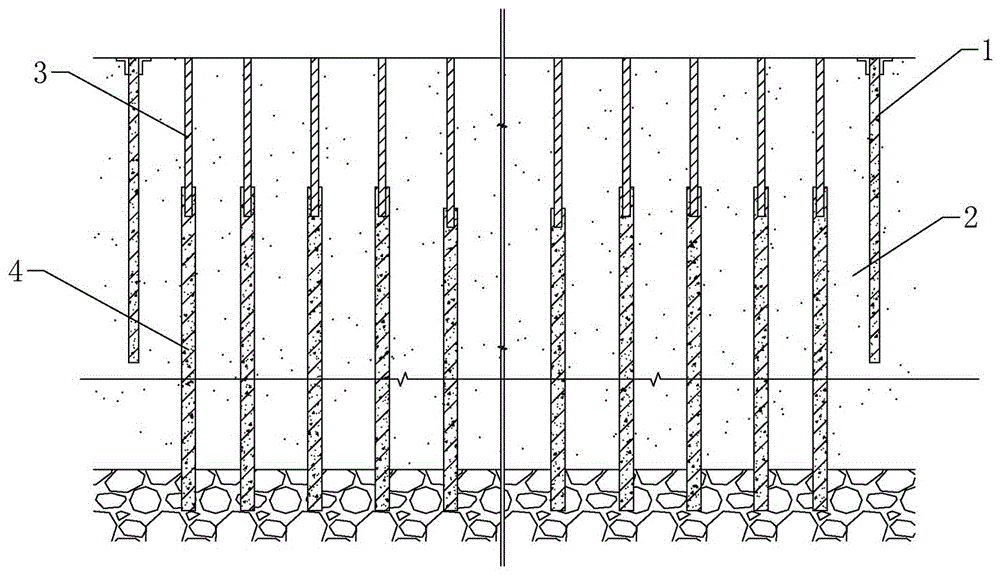

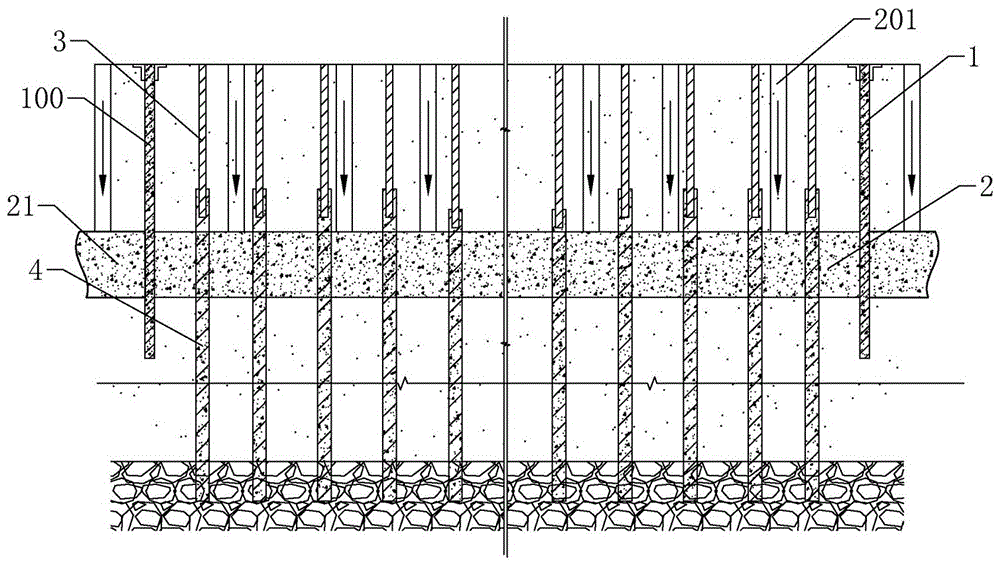

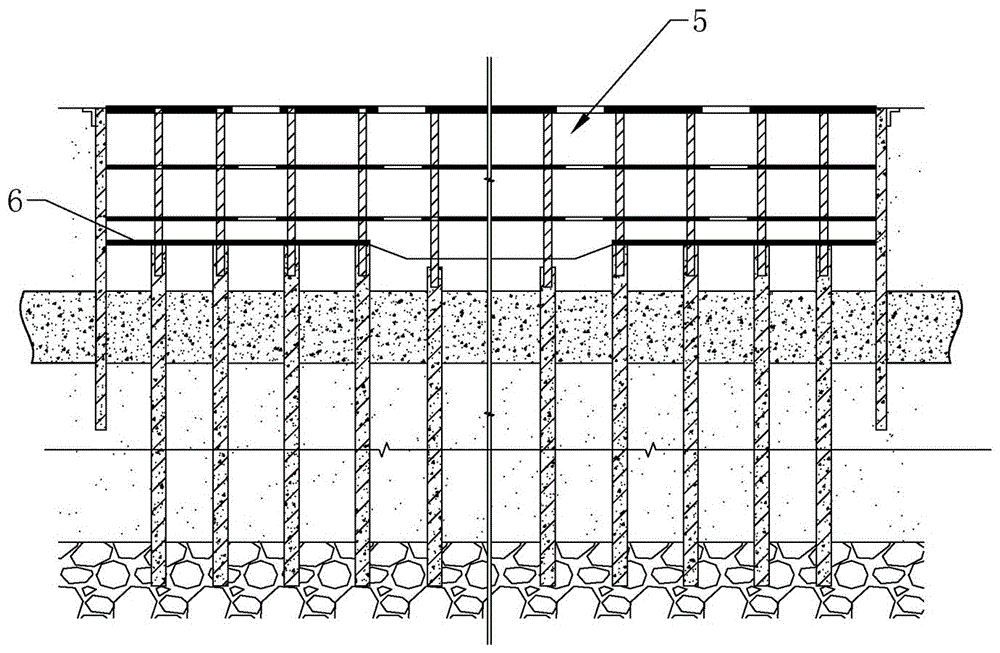

[0037] according to Figure 1 to Figure 5 As shown, a basement waterproof foundation pit structure, comprising: a basement main body 5, a foundation pit enclosure wall 1, a basement reinforcement anti-seepage layer 2 and a plurality of upright piles 3 and engineering piles 4 in the foundation pit, one upright pile 3 and An engineering pile 4 is connected into a column pile, and the engineering pile 4 is arranged under the column pile 3 in the column pile, and the bottom of the engineering pile 4 is embedded in a water-resisting layer or a rock formation, and the top of the column pile 3 is at the same level as the top of the foundation pit. Figure 5 As shown, a grouting layer is arranged between the pile bottom of the column pile 3 and the pile top of the engineering pile 4; The wall 1 is an underground continuous wall formed by splicing a plurality of spliced prefabricated wall panels 100 with each other. A closed reinforced concrete crown beam is arranged on the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com