An on-line temperature probe for motor rotor

A technology of temperature measuring probe and motor rotor, which is applied in the direction of temperature measurement of moving solids, etc. It can solve the problems that the temperature test paper cannot obtain the rotor temperature in real time, the error cannot be eliminated, and the personal safety risk of the measuring personnel is solved, so as to solve the problem of heat loss and safety. Risk, convenient and quick installation, accurate measurement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

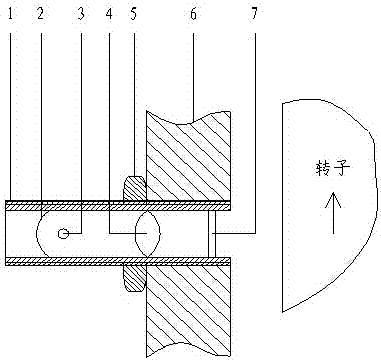

[0014] An online motor rotor temperature measuring probe, characterized in that: the temperature measuring probe is composed of reflector 2, infrared light source 3, focusing mirror 4, optical filter 7, heat insulation cover 1, fixed back cap 5, reflector, infrared light source , focusing mirror and optical filter are integrally installed in the heat insulation sleeve 1 through the fixed back cap 5 in sequence, and are installed on the motor end cover 6 through threads. When the motor is energized and the rotor rotates, the temperature measuring probe can continuously obtain the temperature signal of the rotor end surface. The heat insulating sleeve 1 is made of ABS plastic, the outer diameter is M16 thread, the inner diameter is 8.3 mm, the length is 60 mm, the inner cavity is vacuum-plated with aluminum, and the film thickness is 40 μm. The front end of the inner cavity of the heat insulation sleeve is set with M9 thread, and the aluminum plug is installed, and the thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com