Process of producing production line and system of assembling circuit board with components

A printed circuit board, production line technology, applied in electrical components, electrical components and other directions, can solve the problems of weakening placement efficiency, unsatisfactory printed circuit boards, impossible production line definition and optimization, etc., to achieve high utilization rate, flexible Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

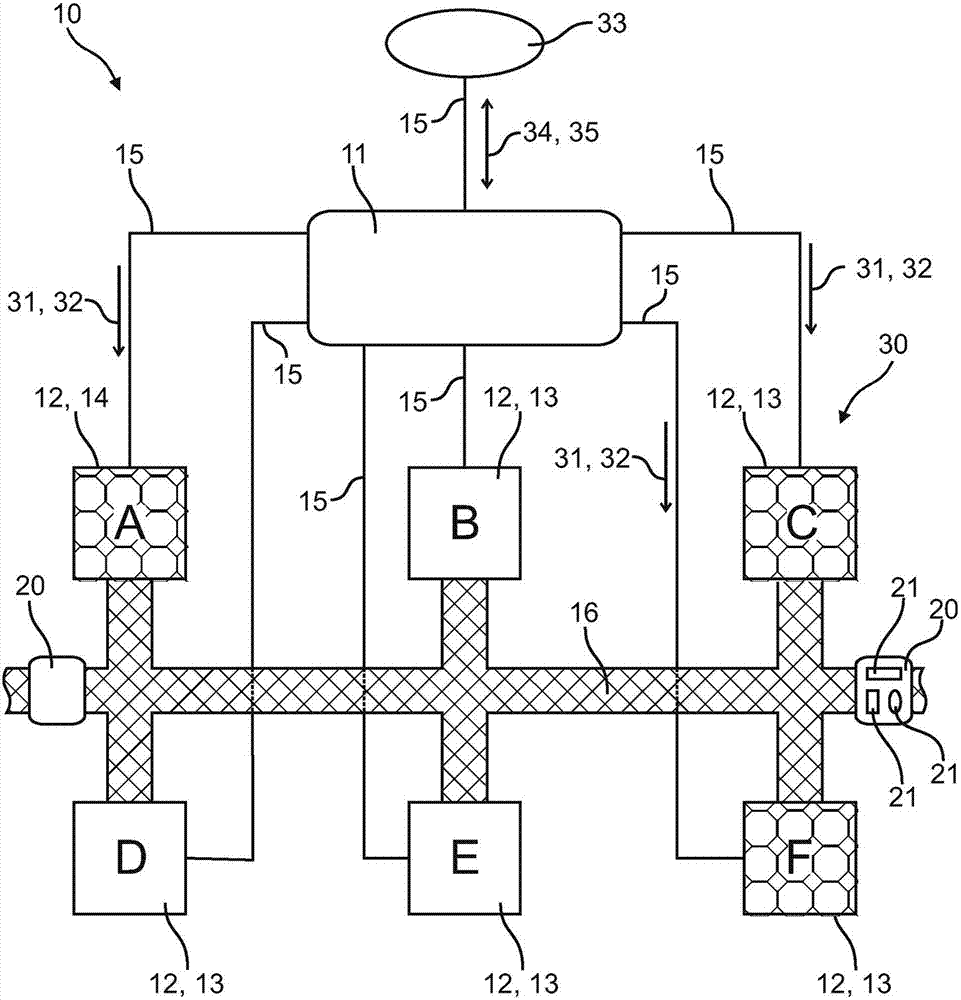

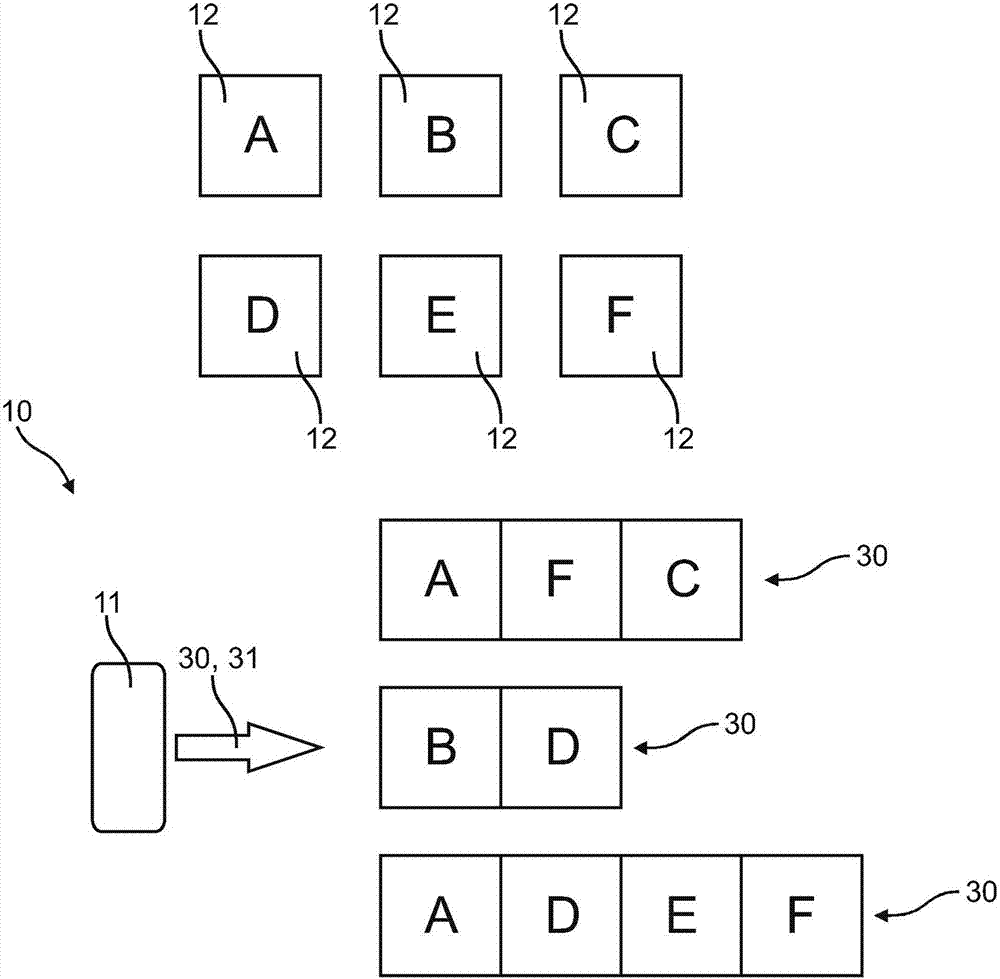

[0048] figure 1 The system 10 of the present invention is shown, and its structure can complete the process of the present invention. In particular, the system 10 according to the invention has a control unit 11. In addition, a number of production units 12 are also displayed, which are marked with capital letters A-F to distinguish them. One of the production units 12 is a printing device 14, and the remaining production units 12 are automatic placement machines 13. All production units 12 are connected to the control unit 11 through a data connection 15. In this way, for example, the recording of a single production unit 12 in the process step a of the present invention can be realized. At this time, the control unit 11 can obtain, for example, the type of the relevant production unit 12, and can also obtain the position information 34 of the relevant production unit 12, for example. In addition, the information 34 can also be stored in the database 33, and this storage ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com