Gas-liquid double flow type variable transmission system

A transmission system, dual-flow technology, applied in the device, application, animal husbandry and other directions of catching or killing insects, can solve the problems of waste of liquid medicine, pollution of the environment, lack of target detection objects, etc., to reduce environmental pollution and improve spraying. Efficient and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

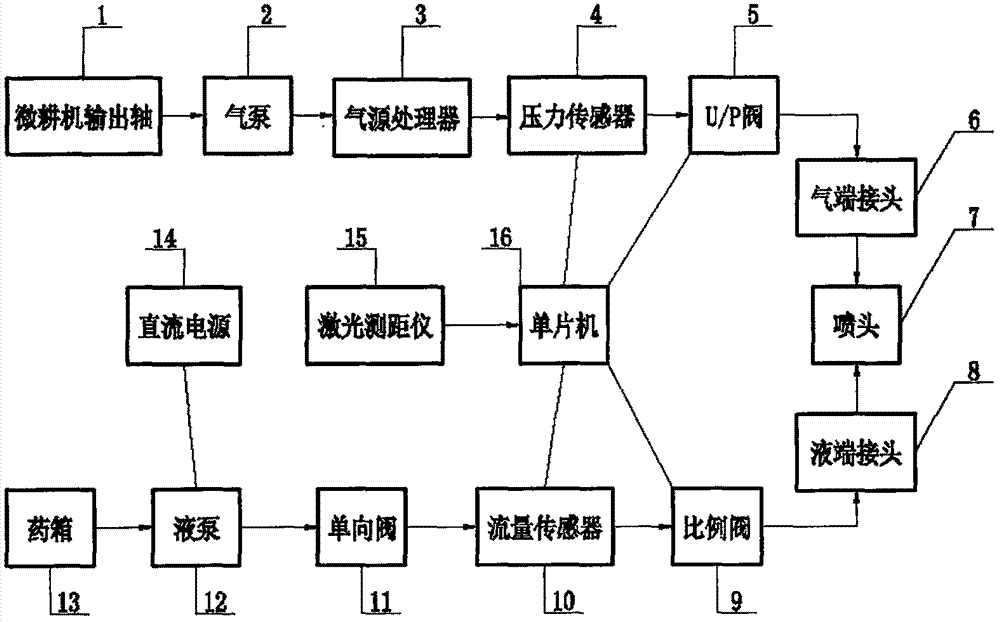

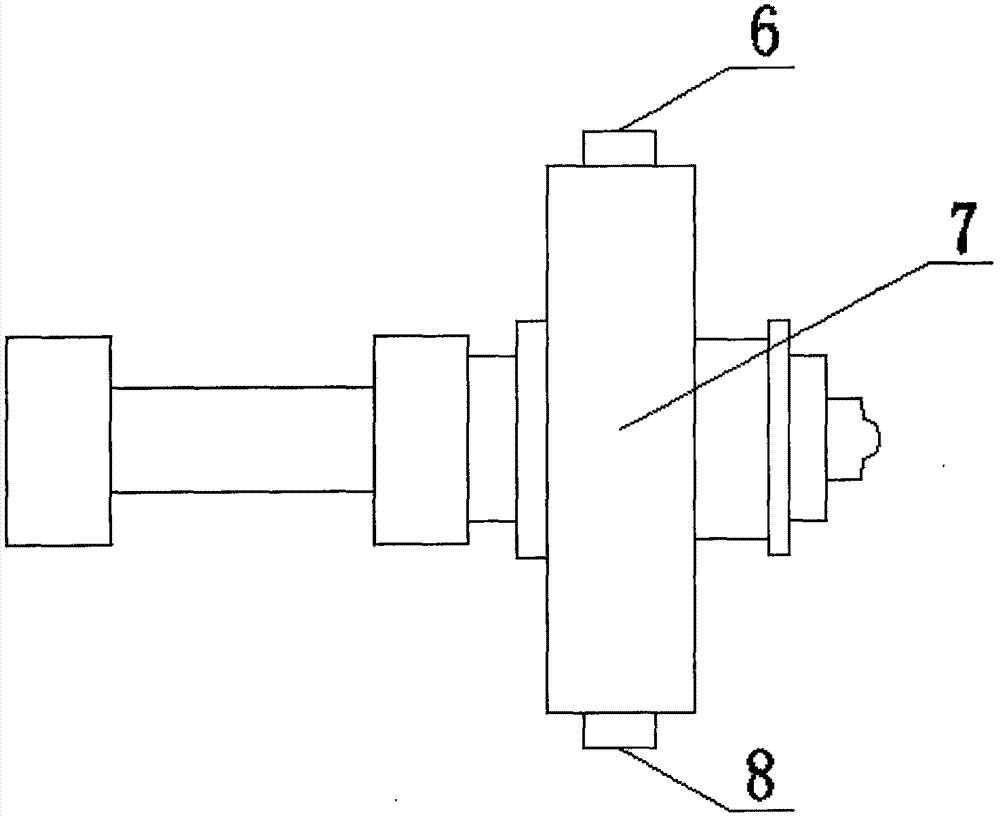

[0013] Attached below figure 1 and figure 2 The present invention is described further:

[0014] A gas-liquid double-flow variable transmission system, including a tiller output shaft 1, an air pump 2, an air source processor 3, a pressure sensor 4, a U / P valve 5, a gas end connector 6, a nozzle 7, a liquid end connector 8, Proportional valve 9, flow sensor 10, one-way valve 11, liquid pump 12, medicine box 13, DC power supply 14, laser rangefinder 15, single-chip microcomputer 16, it is characterized in that: the air pump 2 is connected to the output shaft 1 of the tiller Above, the gas source processor 3 is connected to the gas pump 2. After the gas is output from the gas source processor 3, it passes through the pressure sensor 4, the U / P valve 5 and the gas end connector 6 to the nozzle 7 in turn. The pressure Sensor 4 is connected on the single-chip microcomputer 16, and described U / P valve 5 is connected on the single-chip microcomputer 16, and described liquid pump 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com