Anti-cavitation high-lift centrifugal pump impeller

A centrifugal pump impeller and high-lift technology, which is applied in the direction of pumps, pump components, non-variable pumps, etc., can solve the problems of centrifugal pump head reduction, etc., and achieve the improvement of output head, the reduction of cavitation volume, and the expansion of high-efficiency operating areas Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

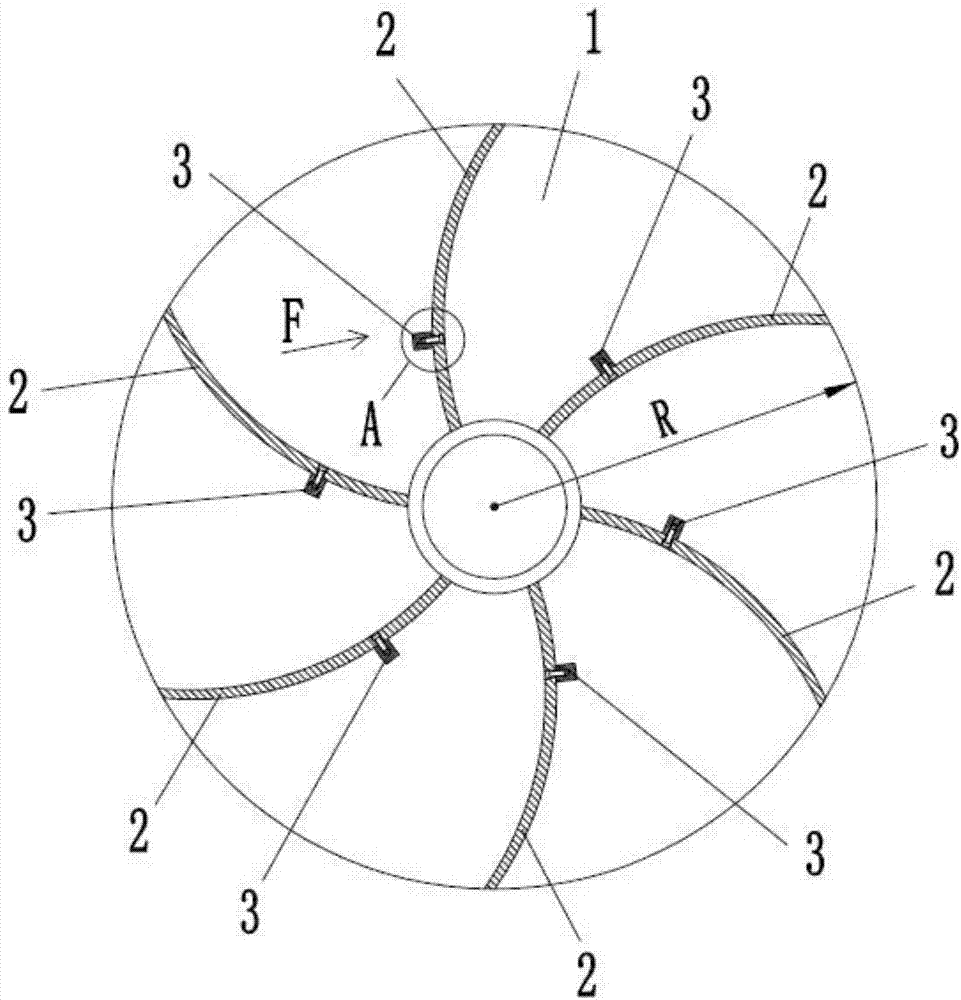

[0019] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

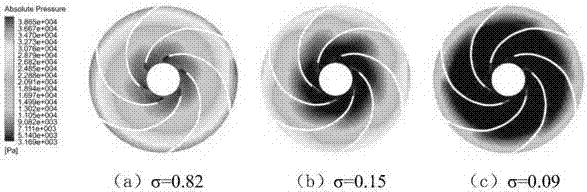

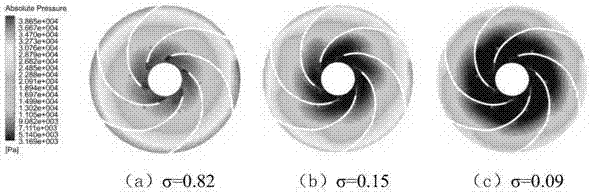

[0020] combine figure 1 , figure 2 and image 3 As shown, the anti-cavitation high-lift centrifugal pump impeller of the present invention includes a cover plate 1 , a blade 2 and a boss 3 , wherein the boss 3 is fixedly connected to the working surface 21 of the blade 2 . Based on the central axis of the impeller, the position of the boss 3 on the working surface 21 is: radial position r=K r ×R; the axial position is 1 / 2 of the axial section line 211 on the working surface 21 at the radial position r. The external structure dimension of the boss 3 is: the length dimension a=K of the cross section a ×R; the width dimension of the cross section b=K b ×R; the height dimension h=K from the top of the boss 3 to the working surface 21 h ×R. Among them, R is the radius of the impeller; K r is the radial position coefficient, K r =0.20~0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com