Energy-saving type straight wall front and back disc variable camber curve element ternary impeller and centrifugal draught fan with impeller

A three-dimensional impeller, variable curvature technology, applied in non-variable-capacity pumps, components of pumping devices for elastic fluids, pump components, etc. Impeller application and other issues to achieve the effect of weakening the drastic changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

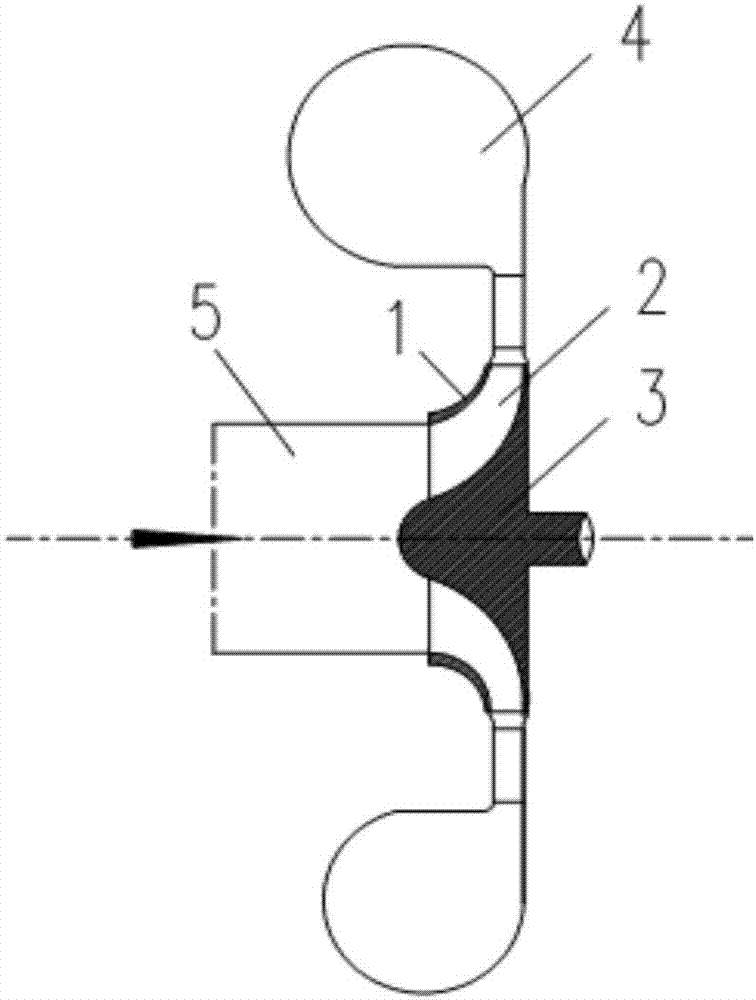

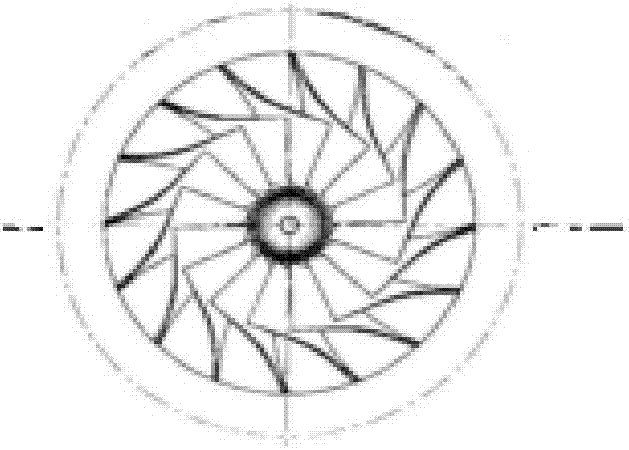

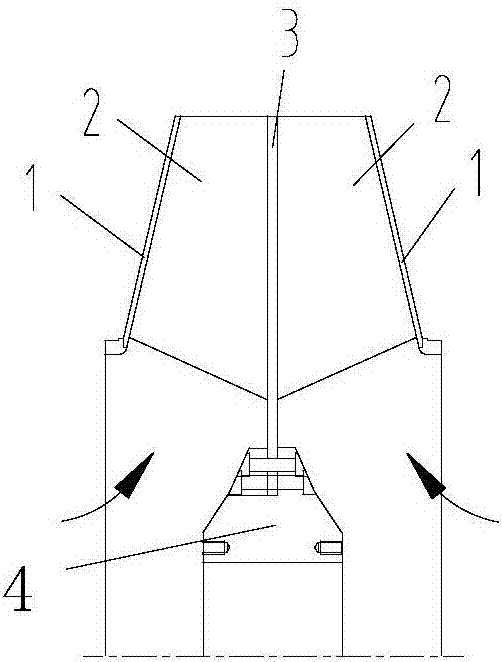

[0041] The present invention provides an energy-saving three-dimensional impeller centrifugal fan with straight-walled front and rear disks with variable curvature curve elements. Under the structural constraints of the traditional low-end fans with straight-walled front and rear disks, the " Radial and mixed-flow turbomachinery positive proposition aerodynamic design method", abandoned the restriction of the American NREC three-dimensional impeller linear element blade, designed a variable curvature curve element three-dimensional impeller (such as Figure 5 and Figure 6 shown), including front disc 1, blade 2, rear disc 3, shaft disc 4, etc., wherein the vane 2 is a ternary blade with variable curvature curve elements.

[0042]The three-dimensional twisted blade of the variable curvature curve element of the present invention is that the bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com