Lifting gate type internal solitary wave generating device

An internal solitary wave and wave-making device technology, used in measuring devices, instruments, fluid dynamics tests, etc., can solve the problems of fluid disturbance, easy failure of water tightness, inconvenient reset of the gate plate, etc. Sufficient, highly automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

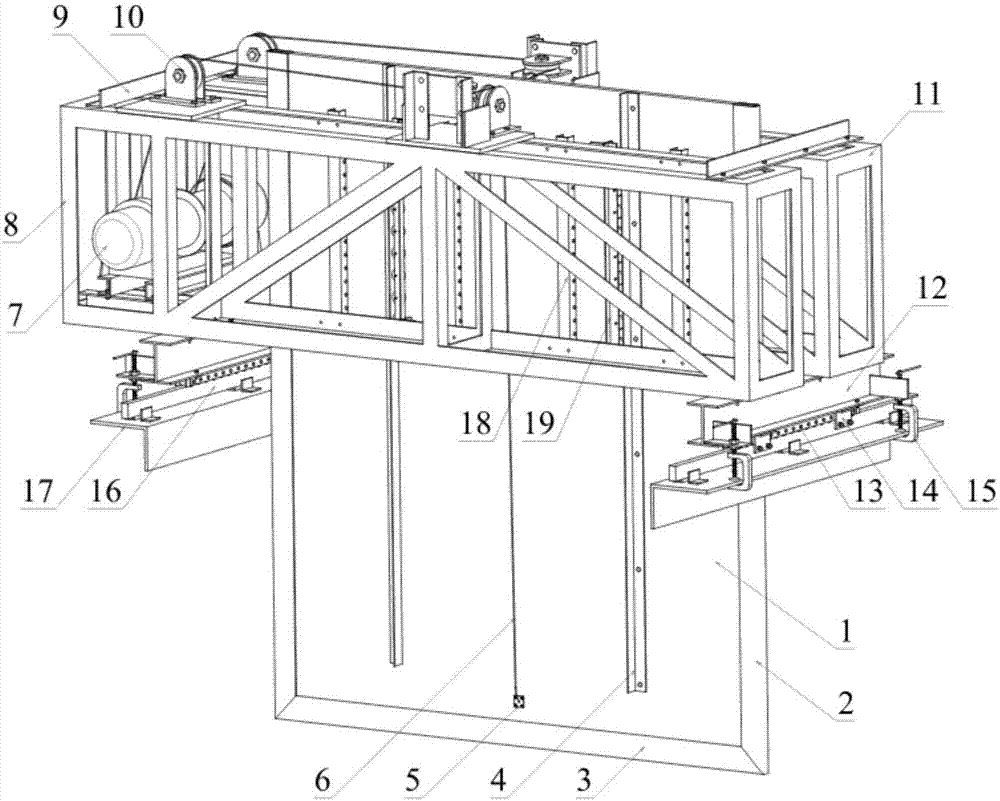

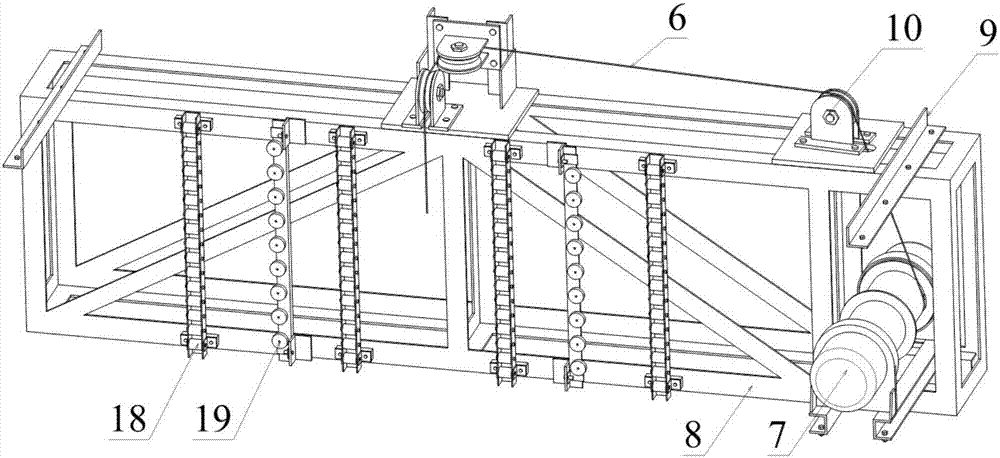

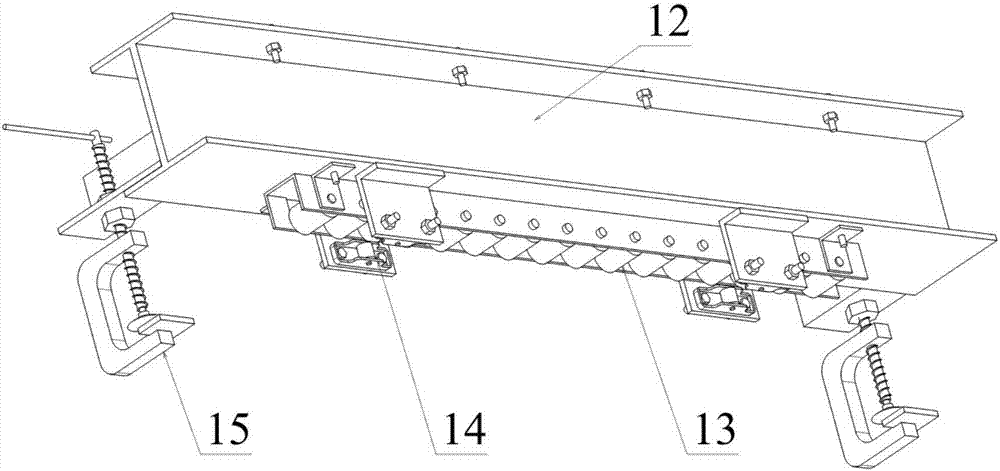

[0028] Such as figure 1 with figure 2 As shown, in Embodiment 1 of the present invention, including a gate plate, a bracket and a lifting device, the gate plate 1 is arranged with elastic materials 2 on the left and right edges, elastic materials 3 are arranged on the bottom edge, and vertically arranged on the front side panel There are several (take two as an example) guide beams 4, and a cable fairlead 5 is installed at the bottom; the support is composed of a transverse support 8 and a transverse support 11 respectively arranged on the front and rear sides of the gate plate 1 and spanning above the water tank; Both the bracket 8 and the transverse bracket 11 are arranged with three fixed pulleys 10 on the top, and there are four conductive fluent strips 18 vertically arranged on the side close to the gate plate 1, and all the conductive fluent strips 18 act on the panel of the gate plate 1 , four conduction fluent strips are arranged in pairs; two space-limiting fluent s...

Embodiment 2

[0032] Such as Image 6 As shown, compared with Embodiment 1, the support also includes a vertical support 21, the vertical support 21 is arranged outside the test water tank, its top is fixed with the horizontal support 8 and the horizontal support 11 at the same time, and four casters 22 are installed at its bottom. The winch 7 of lifting device is installed on the vertical support 21.

Embodiment 3

[0034] In Embodiment 3 of the present invention, the bracket and the lifting device are exactly the same as those in Embodiment 1 or Embodiment 2, but are different on the gate plate, such as Figure 7As shown, the fixing of the elastic material 2 and the panel of the gate plate 1 is strengthened by the cover plate 24, and the cover plate 24 is installed on the gate plate 1 by fasteners 25; the fixing of the elastic material 3 and the panel of the gate plate 1 is carried out by a cover plate 23 For reinforcement, the cover plate 23 is mounted on the gate plate 1 by fasteners 25 .

[0035] In the above embodiment of the present invention, the gate plate 1 adopts a 18mm thick Chevron board, the elastic material 2, the elastic material 3 and the buffer pad 20 all adopt a 3mm thick strong sponge single-sided adhesive tape, and the guide beam 4 adopts a stainless steel angle iron. The cable guide 5 adopts a stainless steel round pipe with a flange seat, the cable 6 adopts a stainle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com