Precise coconut shell stripping device

A coconut shell and precise technology, which is applied in the field of precise coconut shell stripping devices, can solve the problems that product quality cannot be guaranteed, coconut meat cannot be guaranteed, and production efficiency is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

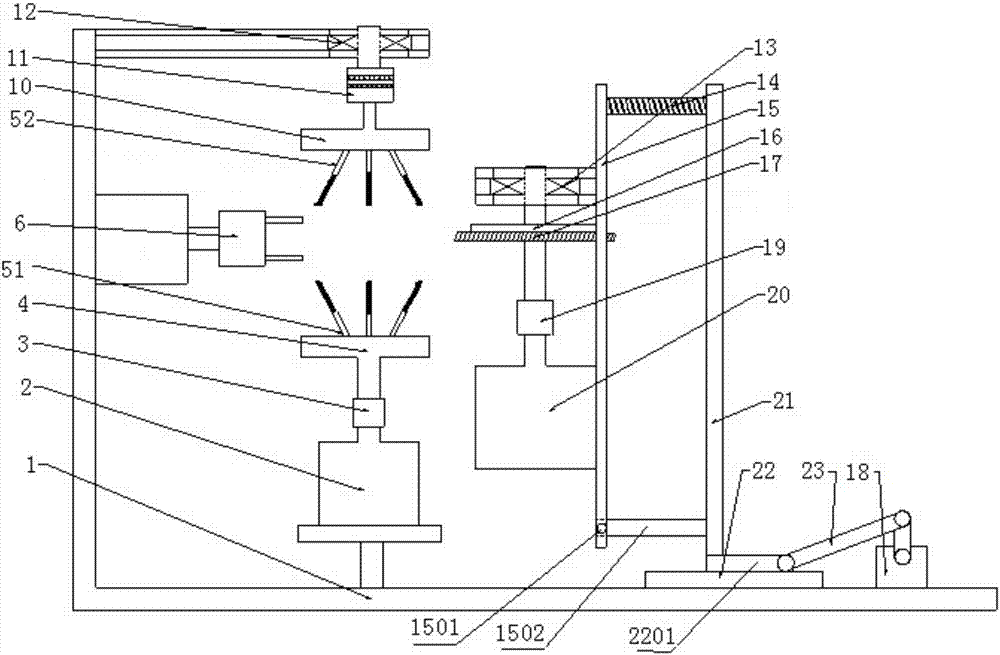

[0023] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

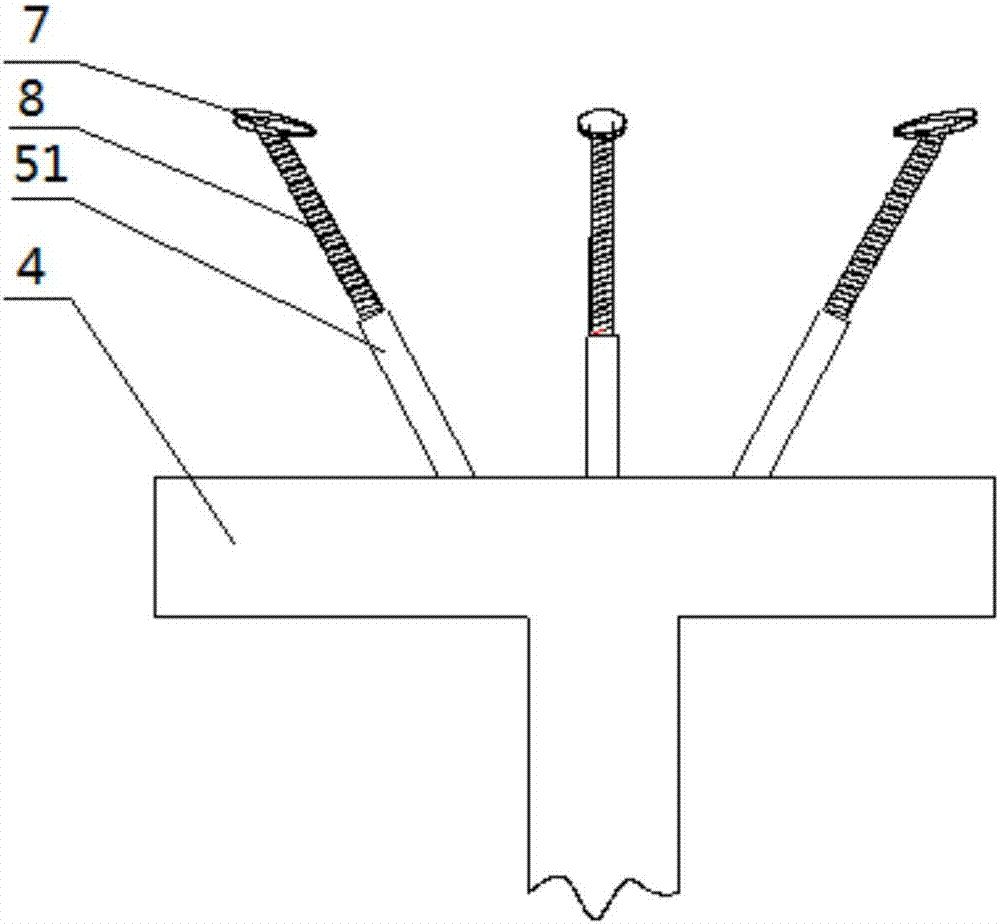

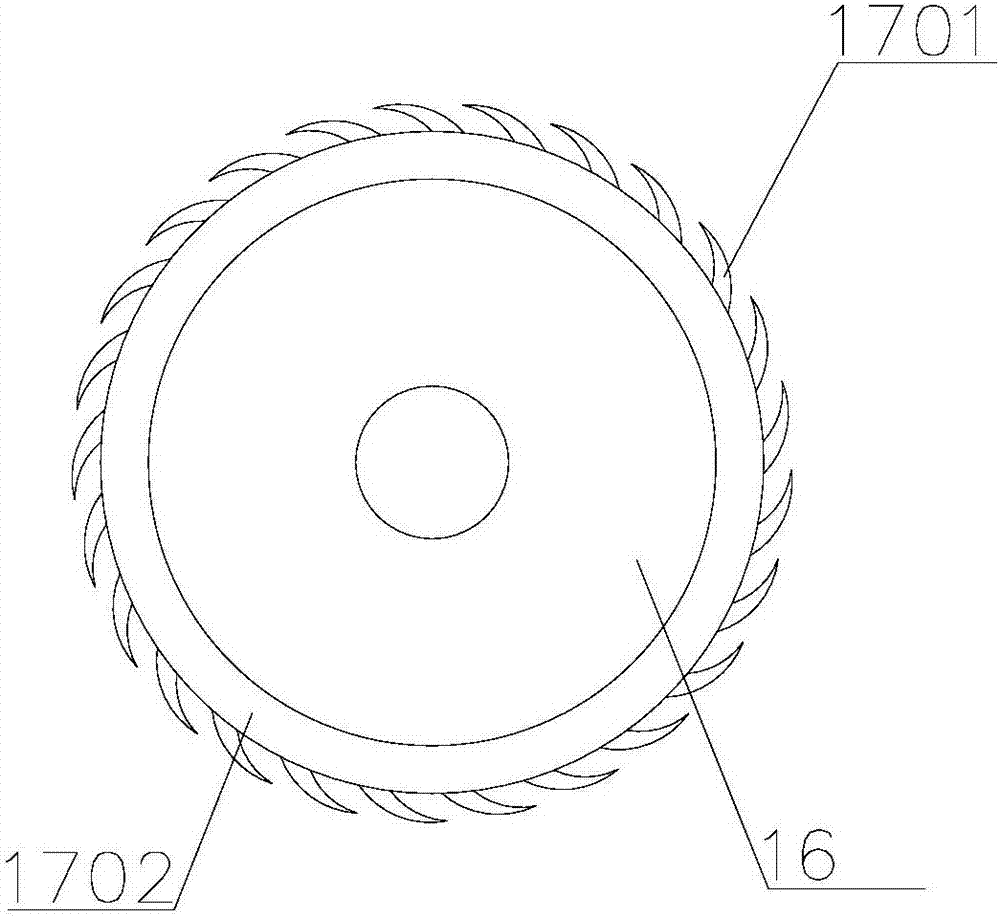

[0024] A device for precisely stripping coconut shells, comprising a base 1, on which a rotating motor 2 is vertically arranged, the rotating shaft of the rotating motor 2 is connected to a lower fixed disk 4 through a first coupling 3, and a lower fixed disk is arranged in the middle of the upper surface of the lower fixed disk. There are several fixed rods 51 and lower fixed rods 51. The lower fixed rods 51 and the lower fixed disc 4 are at an angle of 10 to 80 degrees, and are evenly distributed in a petal shape. The upper fixed plate 10 is set above the lower fixed rod 51, and several upper fixed rods 52 are arranged in the middle of the lower surface of the upper fixed plate 10. The upper fixed rods 52 and the upper fixed plate 10 are at an angle of 10 to 80 degrees, and are petal-shaped and uniform. The divergence is arranged in the middle pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com