Hammer head and forging hammer

A hammer head and head technology, applied in the field of hammer heads, can solve problems such as high consumption, and achieve the effect of improving efficiency and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

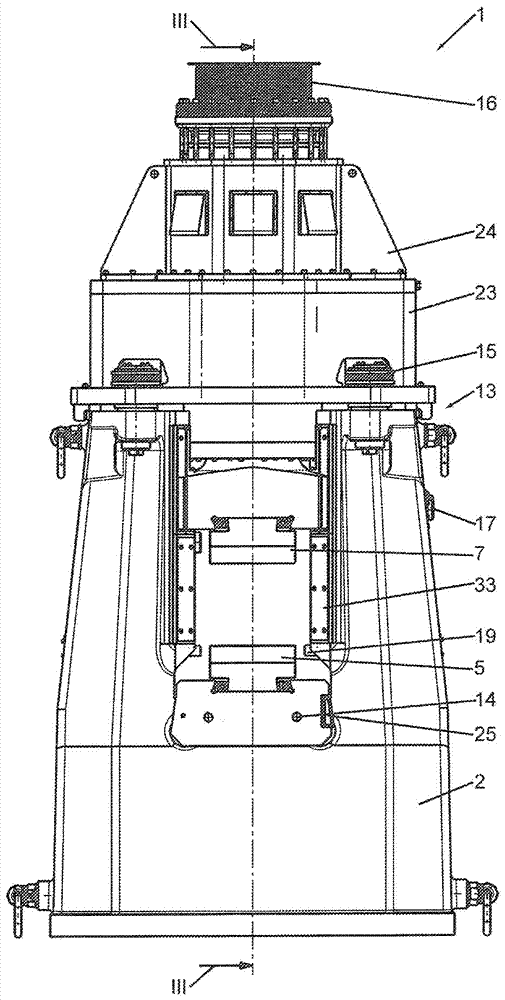

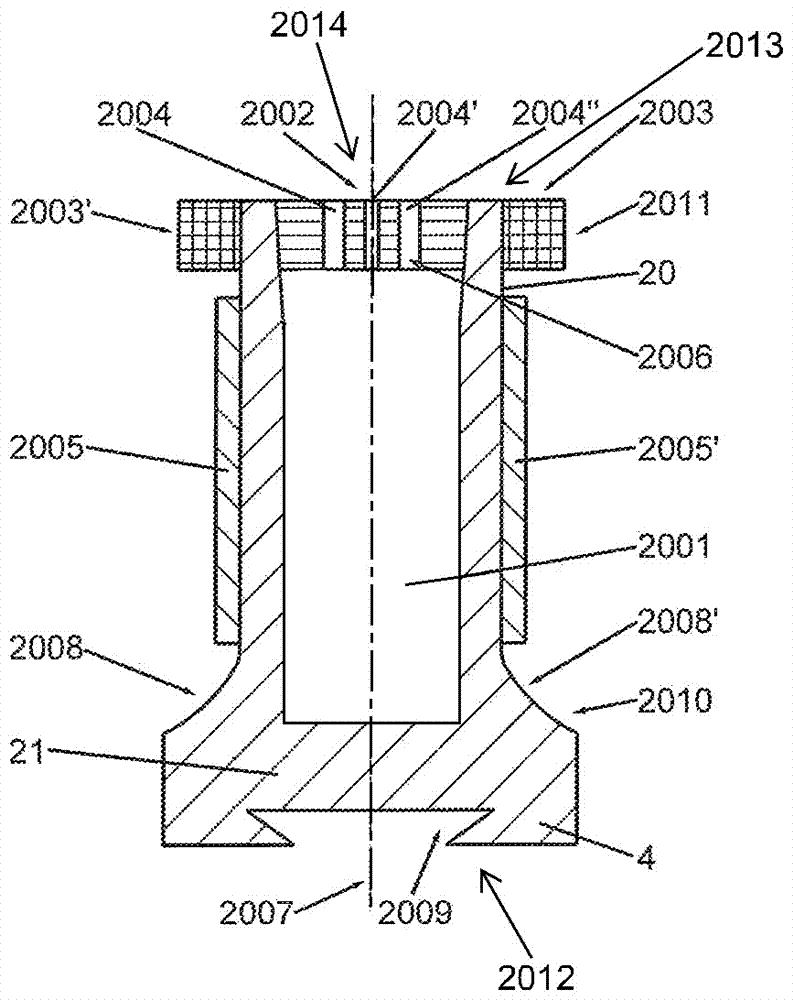

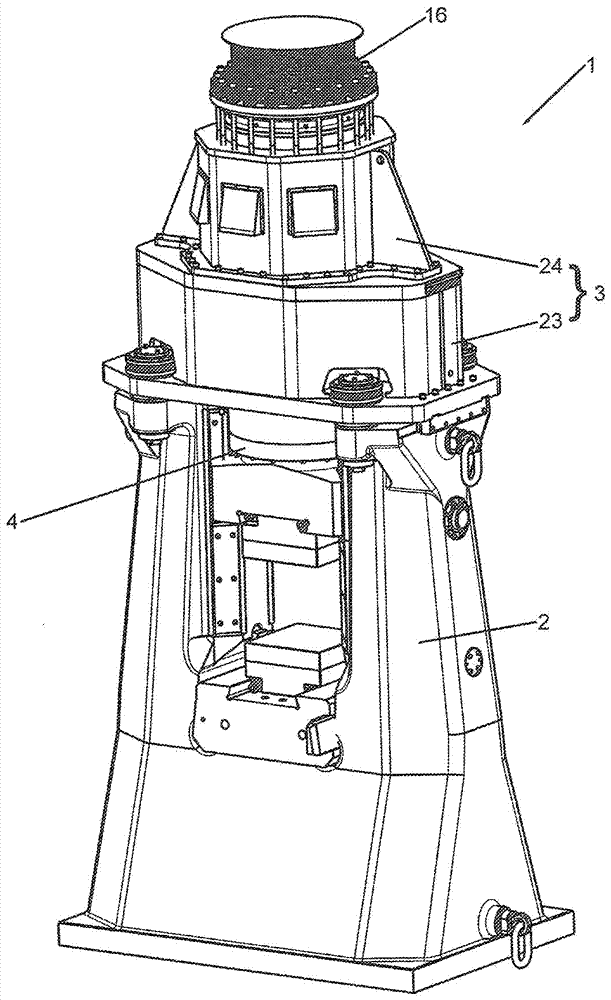

[0079] figure 1 A perspective illustration of the forging hammer 1 is shown. It comprises an anvil 2 having a substantially U-shaped profile. A head section 3 is arranged on the anvil 2 . In the exemplary embodiment shown, the head section 3 is composed of a lower head section 23 and an upper head section 24 . In a manner not shown further, the header section 3 can also be designed in one piece. A cover 16 is arranged on the head section 3 or on the upper head section 24 . A striker 4 is arranged in the anvil 2 . The forging hammer 1 comprises an upper part 7 of a forging die 6 and a lower part 5 of the forging die 6 for machining a workpiece (not shown).

[0080] exist figure 2 is shown in schematic side view already in figure 1 The forging hammer 1 shown in. The forging hammer 1 is designed as a short-stroke die hammer (Kurzhub-Gesenkhammer). The forging hammer 1 comprises the mentioned anvil 2 , an anvil insert 14 , a head section 3 and a hammer head 4 . The head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com