Full-automatic part automatic assembly machine and assembly method thereof

A fully automatic, assembly machine technology, used in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as low efficiency of manual assembly, inability to improve accuracy, and limited product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

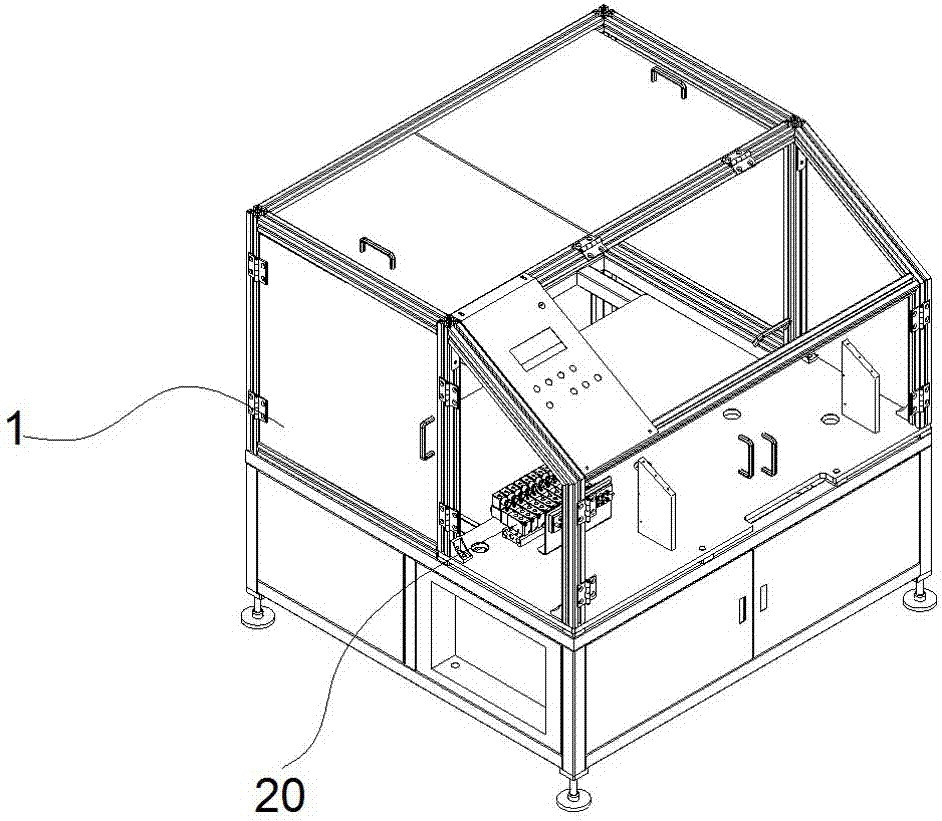

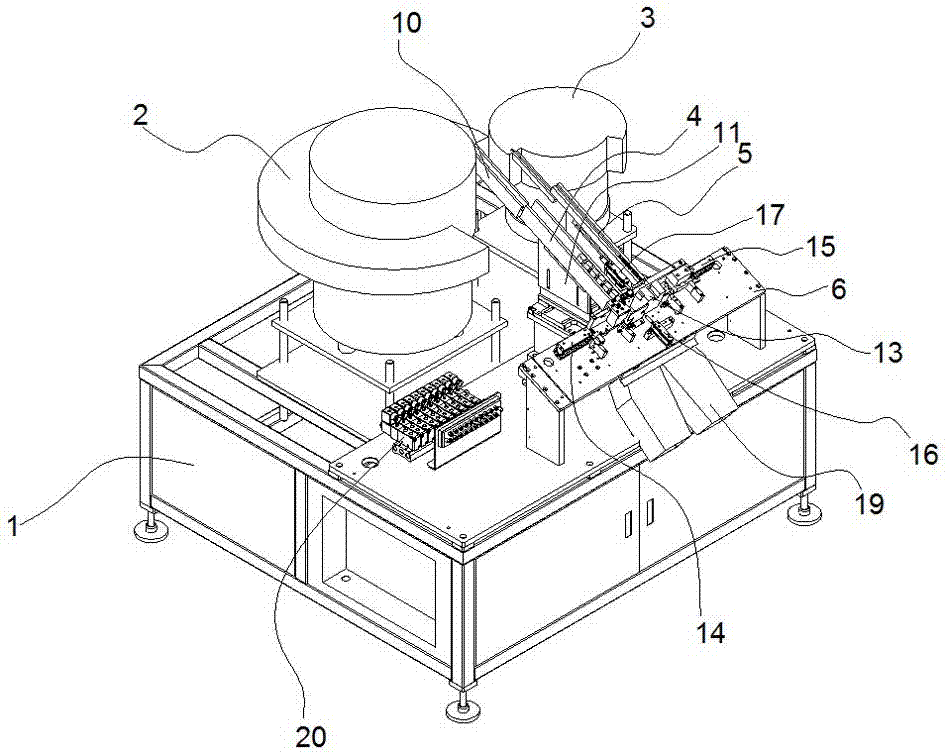

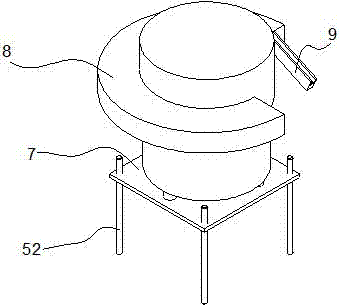

[0077] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 and Figure 14 As shown, a fully automatic parts automatic assembly machine is characterized in that: it includes a frame 1, and the frame 1 is provided with a large vibration plate group frame assembly 2, a small vibration plate group frame assembly 3, a large straight The vibration frame assembly 4, the small direct vibration frame assembly 5 and the working platform assembly 6, the large vibration plate group frame assembly 2 and the large direct vibration frame assembly 4 are distributed in a matching manner, and the large direct vibration The frame assembly 4 and the working platform assembly 6 are distributed in a mating manner, the small vibration plate group frame assembly 3 and the small direct vibration frame assembly 5 are in a mating distribution, and the small direct vibratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com