Round tube output device

A technology of output device and round tube, applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of poor positioning, affecting product quality, easy to roll, etc., to reduce the impact of production, strong positioning, not easy scrolling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing.

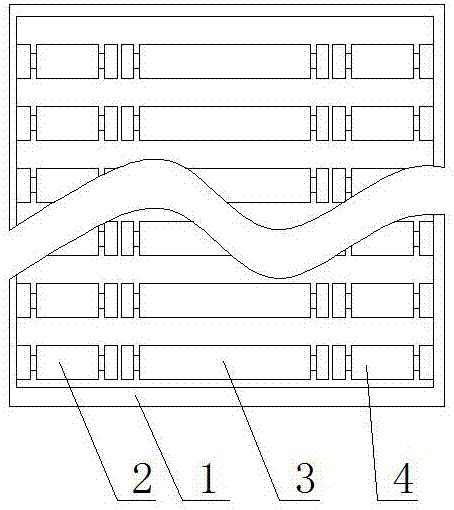

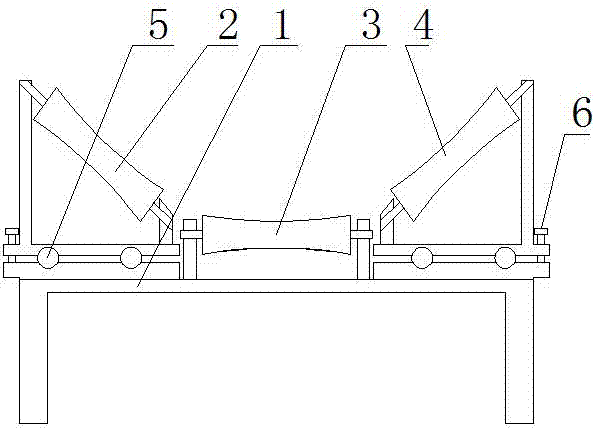

[0012] Such as figure 1 , 2 As shown, the round pipe output device includes a shelf 1, and there are multiple rollers on the shelf. The rollers are horizontally arranged on the shelf, that is, the axes of the rollers and the running of the pipe are vertically arranged on the shelf. It is characterized in that the rollers Divided into three groups of rollers, respectively left roller 2, middle roller 3, right roller 4, left roller, right roller set obliquely, middle roller set horizontally, left roller, middle roller, right roller The wheel is in an upwardly open state. Like this, steel pipe just governs in the middle of left roller 2, middle roller 3, right roller 4, can not roll, has advantage of the present invention.

[0013] Further, each of the rollers is thin in the middle and thick at both ends, and the sides are arc-shaped, so that the effect is better.

[0014]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com