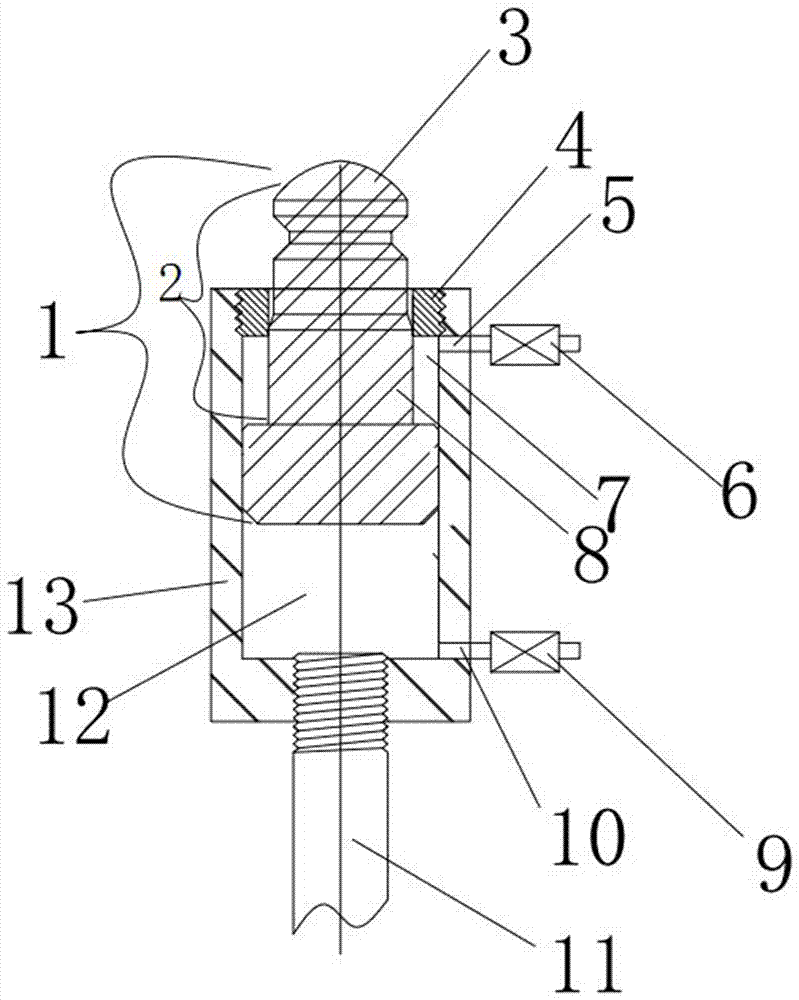

Self-driven pin lock prestressed connecting structure and connecting method

A connection structure and connection method technology, applied in building construction, building material processing, construction, etc., can solve problems such as input cost, and achieve the effect of facilitating on-site construction, reducing equipment requirements, and expanding application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

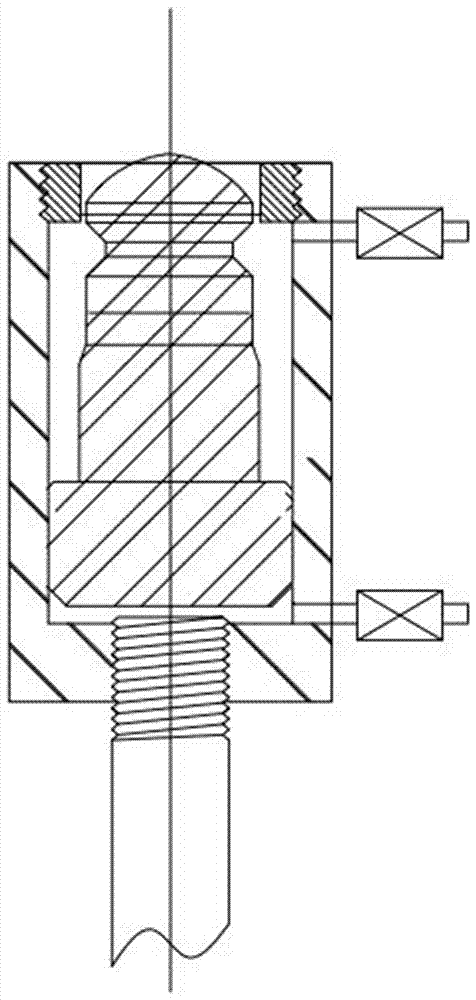

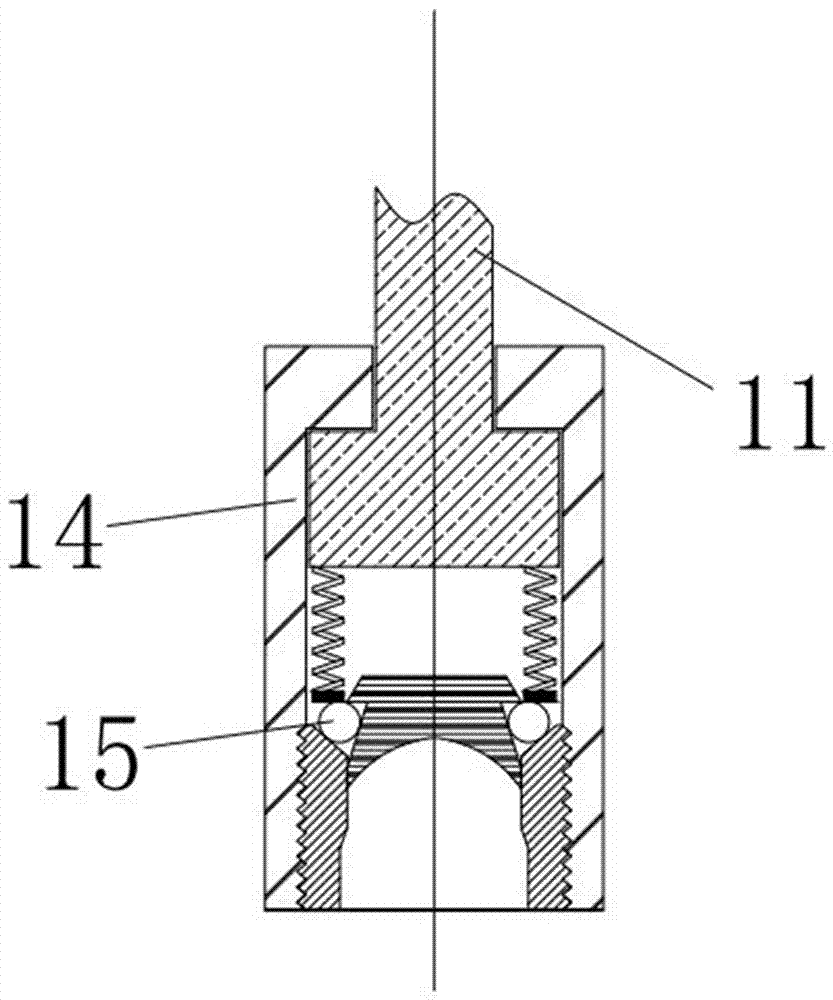

Method used

Image

Examples

Embodiment 1

[0050] The construction personnel install the bolt part and the lock part respectively on the construction workpiece 11 to be connected, and inject the fast solidification liquid into the first thrust chamber through the grouting pipe; after pushing the pin end of the piston of the bolt part into the lock part, close the second A check valve 9 maintains the hydraulic pressure in the first thrust chamber until the liquid is solidified. At this time, the pin part and the locking part are fixed as a whole to form a connection pair to connect the two construction workpieces 11, and the connection pair has precompression stress.

Embodiment 2

[0052] After the construction personnel attach the bolt part and the lock part, they operate according to the steps B2, B3 and B4 of the pretension stress connection method, so that the fitted bolt part and the lock part form a connection pair with built-in pretension stress, and then use this A connection pair connects two building elements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com