Repairable electric heating ice-melting wind power generator rotor blade and making method thereof

A technology of wind power generators and rotor blades, which is applied to wind power engines, engines, mechanical equipment, etc., and can solve problems such as air pockets and dry spots that cannot be repaired by electric heating chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

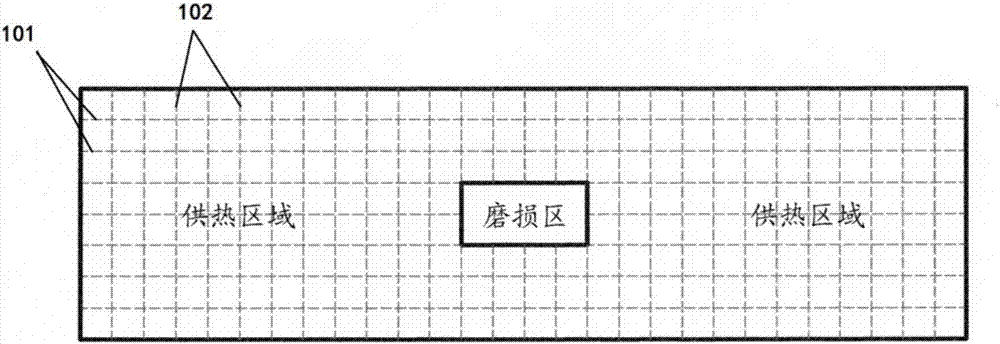

[0042] This embodiment provides a repairable electrothermal ice-melting wind turbine rotor blade, and the blade includes: a repairable carbon fiber electrothermal ice-melting chip (abbreviated as an electrothermal chip).

[0043] The blade also includes: an inner skin glass fiber reinforced plastic layer, a core material, a three-axis glass fiber cloth layer, a two-axis glass fiber cloth layer, and an outer skin glass fiber reinforced plastic layer.

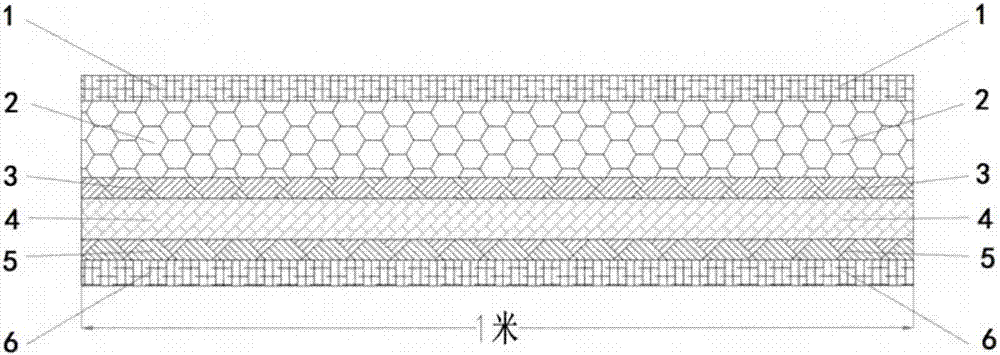

[0044] figure 2 It is a schematic cross-sectional structure diagram of a repairable electrothermal deicing wind turbine rotor blade according to an embodiment of the present invention. Such as figure 2As shown, the repairable electrothermal ice-melting wind turbine rotor blade sequentially includes: inner skin glass fiber reinforced plastic layer 1, core material 2, three-axis glass fiber cloth 3, repairable carbon fiber electric heating ice-melting chip 4, two-axis glass fiber cloth Layer 5, outer skin fiberglass layer 6.

...

no. 2 example

[0056] This embodiment provides a method for preparing a rotor blade of a repairable electrothermal ice-melting wind power generator, and the method includes the following steps:

[0057] Step S1, preparing a repairable carbon fiber electric heating ice-melting chip (hereinafter referred to as the electric heating chip).

[0058] Specifically, carbon fiber bundles are arranged in the warp and weft directions of the glass fiber cloth, and the carbon fiber bundles in the warp and weft directions are connected to each other.

[0059] In this step, the carbon fiber bundles are arranged in the warp and latitude directions of the glass fiber cloth, further as follows: on top of a layer of warp carbon fiber bundles with a fixed spacing, a layer of weft carbon fiber bundles with a fixed spacing is arranged; or on a layer of On top of the weft carbon fiber bundles with fixed spacing, a layer of meridional carbon fiber bundles with fixed spacing is arranged; or the meridional carbon fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com