Organic electroluminescent element, method for producing organic electroluminescent element, display, and lighting device

一种电致发光元件、有机的技术,应用在电气元件、有机半导体器件、半导体/固态器件制造等方向,能够解决发光寿命短、发光强度降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0481] "Manufacturing of Organic EL Elements 1-1"

[0482] After patterning a substrate (NA45 manufactured by NH Technoglass Co., Ltd.) on which ITO (indium tin oxide) was deposited on a glass substrate of 100 mm × 100 mm × 1.1 mm at a thickness of 100 nm as an anode, the ITO transparent electrode was provided. The transparent support substrate was ultrasonically cleaned with isopropyl alcohol, dried with dry nitrogen, and subjected to UV ozone cleaning for 5 minutes.

[0483] This transparent support substrate was fixed to a substrate holder of a commercially available vacuum evaporation apparatus, and on the other hand, 200 mg of HT-1 was placed in a resistance heating boat made of molybdenum, and HT-1 was placed in another resistance heating boat made of molybdenum. 200 mg of HT-2, 200 mg of comparative compound 1 was loaded into another molybdenum resistance heating boat, 200 mg of DP-1 was loaded into another molybdenum resistance heating boat, and 200 mg of DP-1 was load...

Embodiment 2

[0512] "Production of Organic EL Elements 2-1 to 2-5"

[0513] Organic EL elements 2-1 to 2-5 were produced in the same manner as in the production of organic EL element 1-1 in Example 1, except that comparative compound 1 was changed to the host compound described in Table 2.

[0514] "Evaluation of Organic EL Elements 2-1 to 2-5"

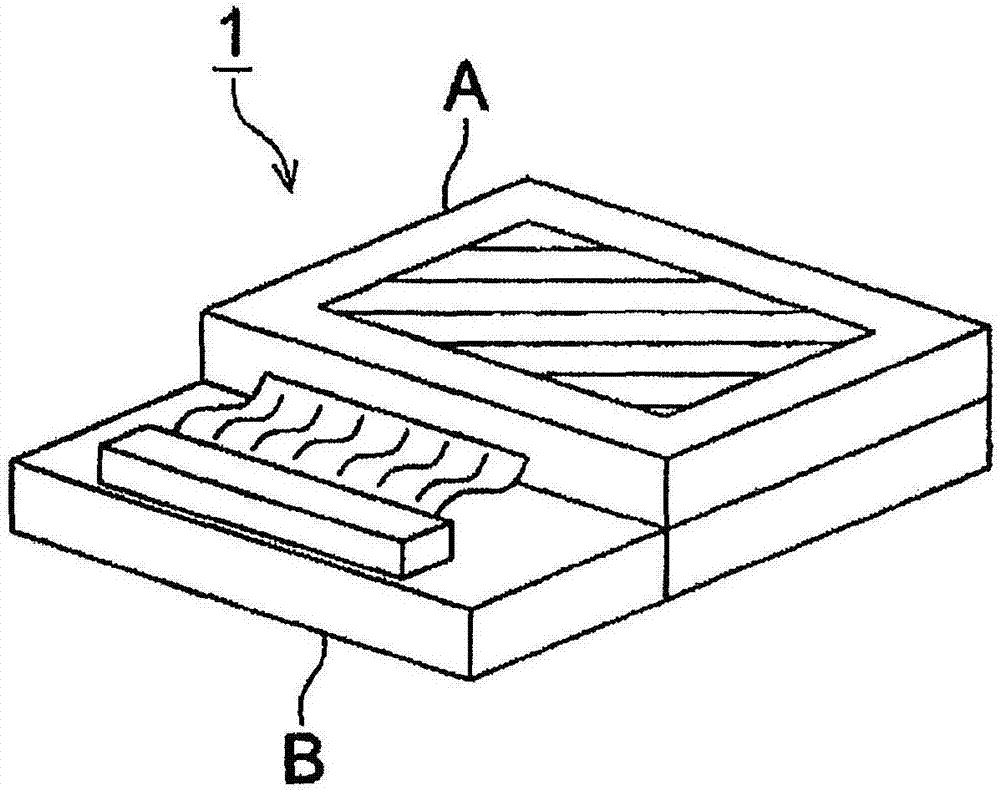

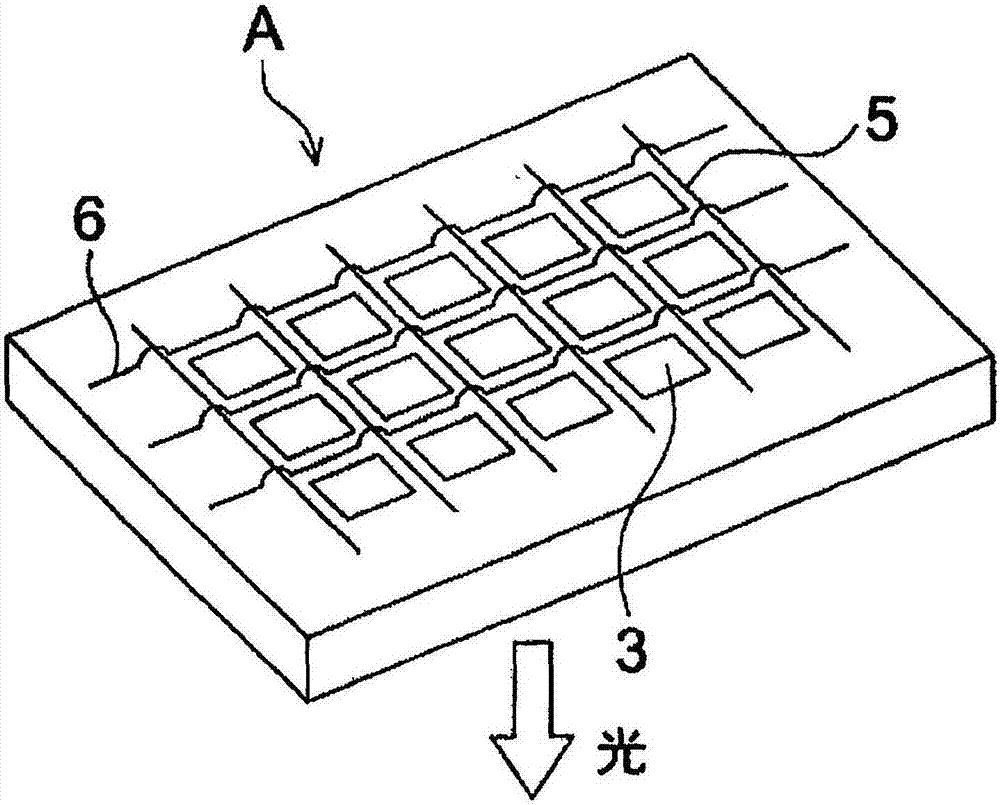

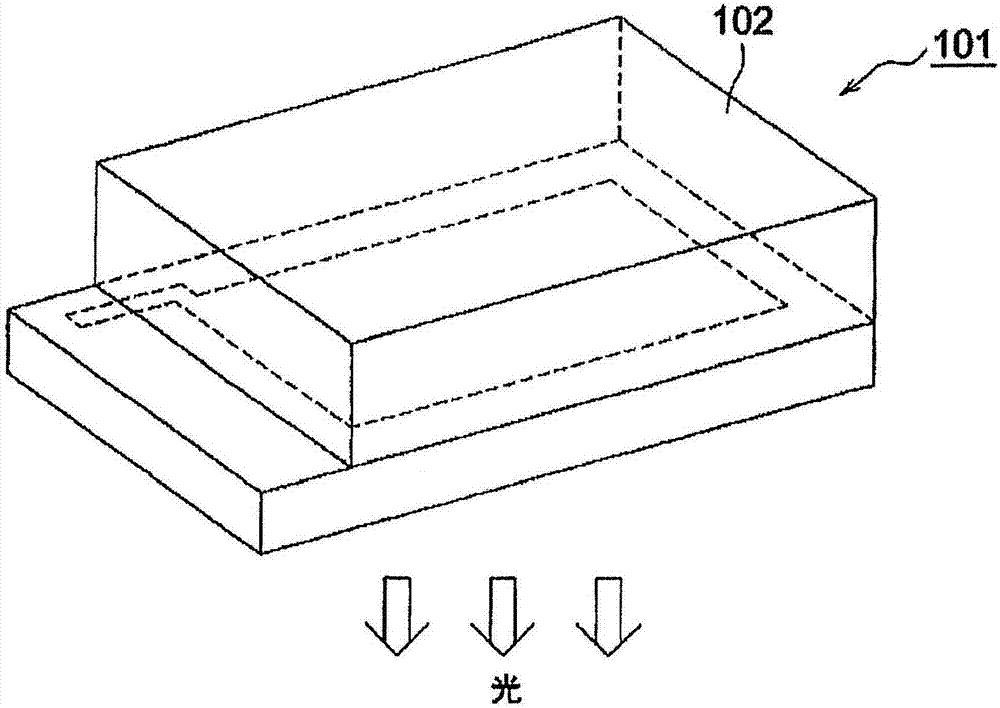

[0515] When evaluating the obtained organic EL elements, they were sealed in the same manner as the organic EL elements 1-1 to 1-12 of Example 1, and produced image 3 , Figure 4 The same items as in Example 1 were evaluated for the lighting device having the structure shown in .

[0516] The evaluation results are shown in Table 2. It should be noted that the external extraction quantum efficiency and the high-temperature half-life are represented by relative values with the organic EL element 2-1 being 100.

[0517] 【Table 2】

[0518]

[0519] As is clear from Table 2, it can be seen that the organic EL elements 2-2 to 2-5 using the c...

Embodiment 3

[0521] "Production of Organic EL Elements 3-1 to 3-12"

[0522] In the preparation of the organic EL element 1-1 of Example 1, except that the comparative compound 1 used in the light-emitting layer was changed to GH-1, and ET-1 was changed to the electron transport material described in Table 3, similarly produced Organic EL elements 3-1 to 3-12.

[0523]"Evaluation of Organic EL Elements 3-1 to 3-12"

[0524] When evaluating the obtained organic EL elements, they were sealed in the same manner as the organic EL elements 1-1 to 1-12 of Example 1, and produced image 3 , Figure 4 The following evaluations were performed on the lighting device having the structure shown in .

[0525] (1) External extraction quantum efficiency, (2) high-temperature half-life, and (3) high-temperature storage stability were evaluated in the same manner as in Example 1.

[0526] (4) Driving voltage

[0527] The organic EL elements were measured at room temperature (about 23°C ~ 25°C), 2.5mA / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com