Method and device for siliconing interior surface of hollow bodies

A hollow body and inner surface technology, applied to the surface coating liquid device, special surface, pre-treated surface, etc., can solve the problems of lack of speed, hollow body damage, lack of accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

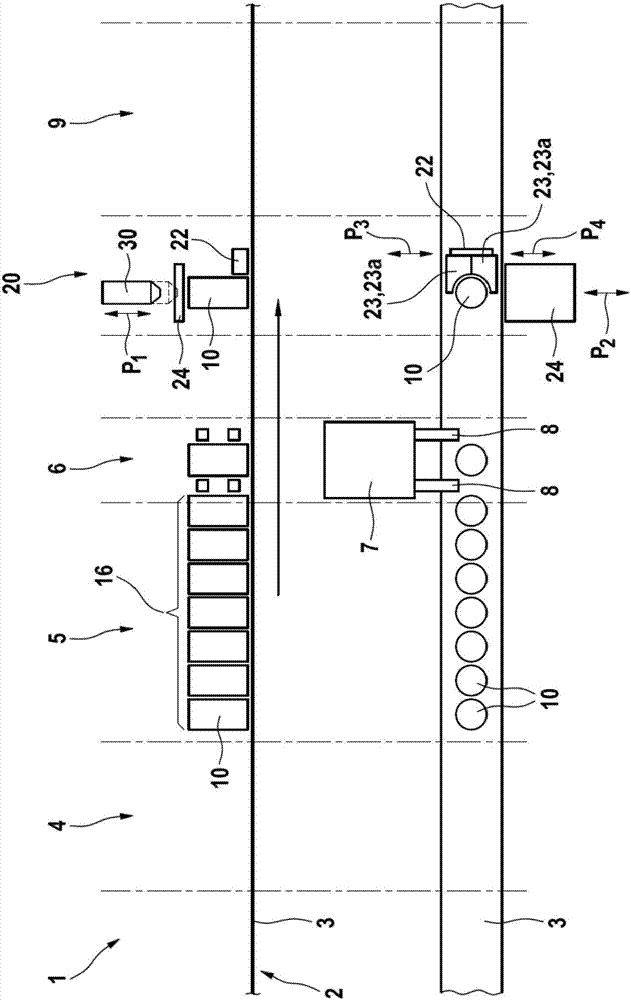

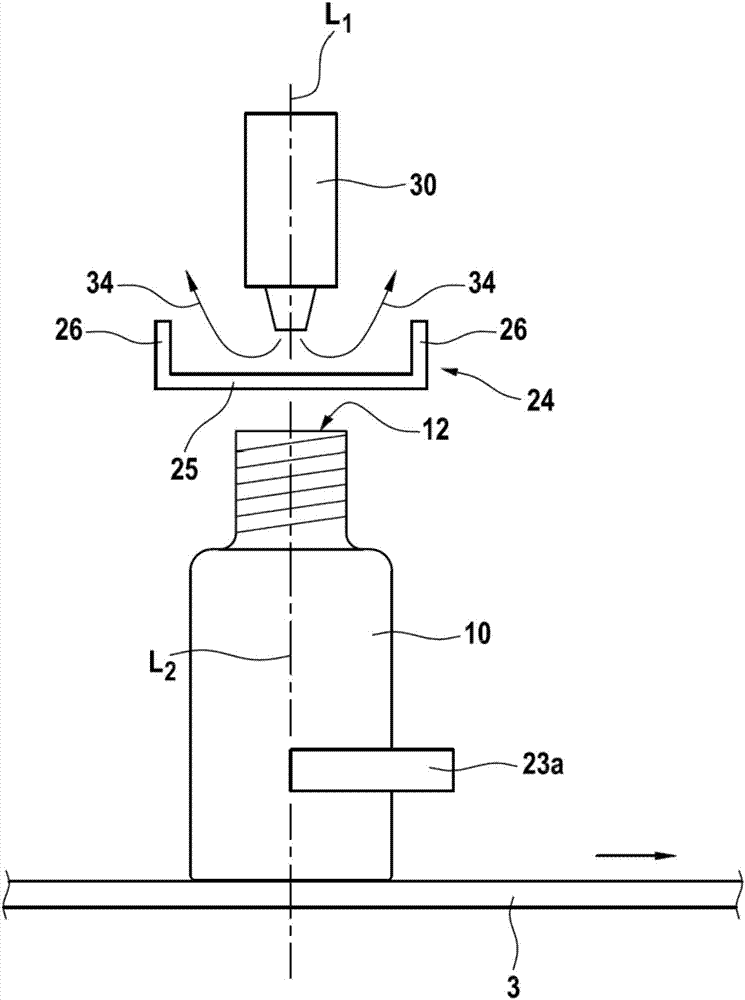

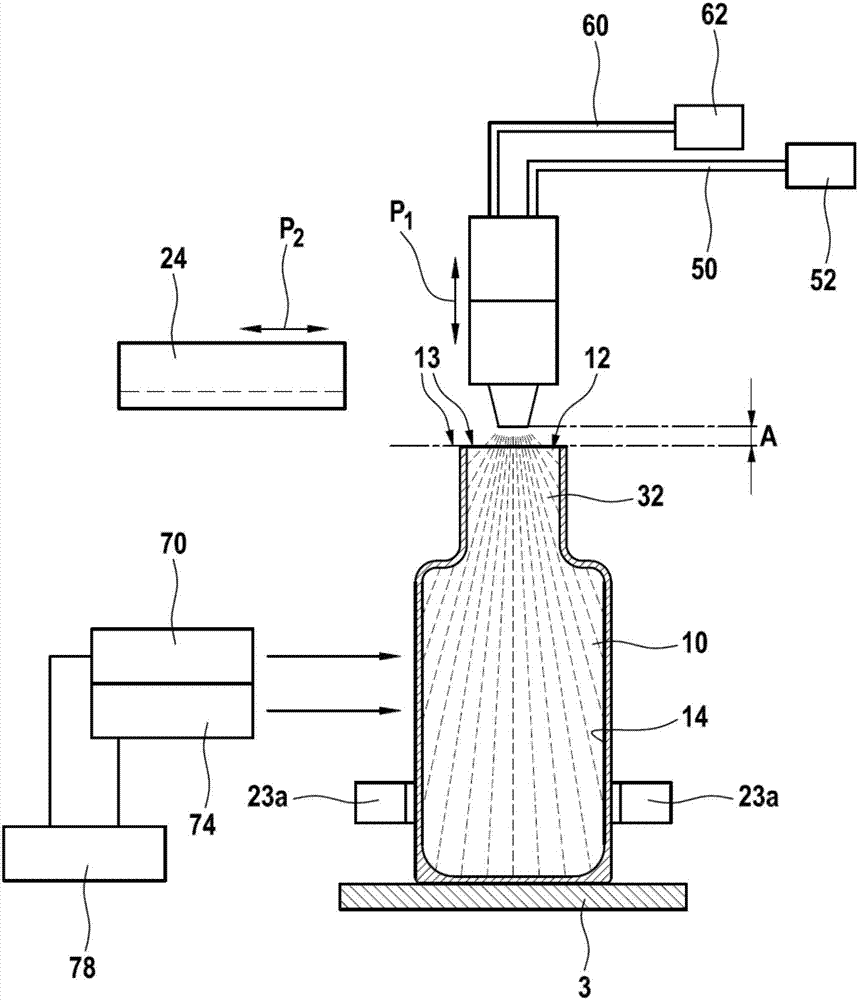

[0051] exist figure 1 shows schematically a coating plant 1 with a transport device 2 with a supply belt 3 on which the hollow bodies 10 to be coated stand and are transported with the openings 12 of the hollow bodies pointing upwards (see also figure 2 and 3 ).

[0052] The hollow bodies 10 first pass through the cleaning station 4 and are then accumulated in the accumulation section 5 . In the following separation station 6 , the hollow bodies 10 to be coated are separated from the group 16 of hollow bodies 10 by means of a separation device 7 , which has a separation gripper 8 , and are subsequently fed to a spraying station 20 .

[0053] In the spraying station 20, the nozzles 30 can be positioned vertically (double arrow P 1 )move. Nozzles 30 shown in dashed lines mark the spraying positions.

[0054] The hollow body 10 to be coated is positioned centrally in the coating station 20 by means of a positioning device 22 which has means 23 in the form of two positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com