Device for recovering dry ice gaseous phase through ammonia heat pump refrigeration and production method

A heat pump refrigeration, ammonia heat pump technology, applied in heat recovery systems, refrigerators, refrigeration components, etc., can solve problems such as increasing the cost of dry ice production, and achieve products with low unit power consumption, safe and reliable operation, and low operating energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

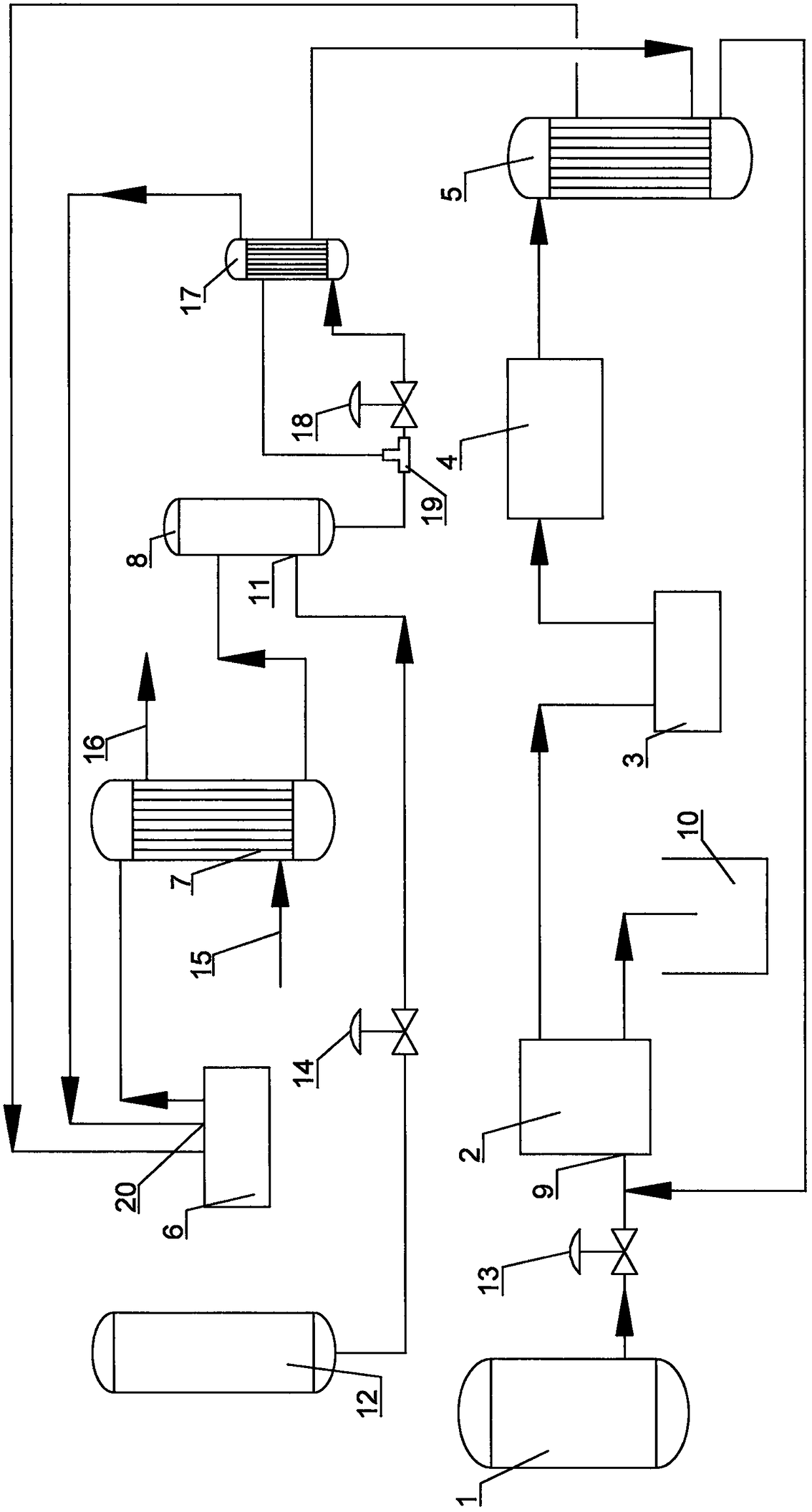

[0031] A device for recovering the gaseous phase of dry ice with ammonia heat pump refrigeration, comprising a carbon dioxide raw material liquid storage tank 1, a carbon dioxide raw material liquid storage tank 1 connected to a carbon dioxide inlet 9 of a dry ice maker 2, and a dry ice outlet of the dry ice maker 2 connected to a dry ice incubator 10 , it is characterized in that: the carbon dioxide gas phase outlet of the dry ice maker 2 is connected to the carbon dioxide inlet 9 of the dry ice maker 2 through the tubes of the carbon dioxide booster compressor 3, the high-efficiency degreaser 4, and the evaporator 5 in sequence; screw refrigeration The outlet of the compressor 6 passes through the tube side of the condenser 7, the liquid accumulator 8, the tee 19, the shell side of the economizer 17, the shell side of the evaporator 5, and is connected with the inlet of the screw refrigeration compressor 6; the first three The third end of the channel 19 is connected to the g...

Embodiment 2

[0040] A device for recovering the gaseous phase of dry ice with ammonia heat pump refrigeration, comprising a carbon dioxide raw material liquid storage tank 1, a carbon dioxide raw material liquid storage tank 1 connected to a carbon dioxide inlet 9 of a dry ice maker 2, and a dry ice outlet of the dry ice maker 2 connected to a dry ice incubator 10 , it is characterized in that: the carbon dioxide gas phase outlet of the dry ice maker 2 is connected to the carbon dioxide inlet 9 of the dry ice maker 2 through the tubes of the carbon dioxide booster compressor 3, the high-efficiency degreaser 4, and the evaporator 5 in sequence; screw refrigeration The outlet of the compressor 6 passes through the tube side of the condenser 7, the liquid accumulator 8, the tee 19, the shell side of the economizer 17, the shell side of the evaporator 5, and is connected with the inlet of the screw refrigeration compressor 6; the first three The third end of the channel 19 is connected to the g...

Embodiment 3

[0049]A device for recovering the gaseous phase of dry ice with ammonia heat pump refrigeration, comprising a carbon dioxide raw material liquid storage tank 1, a carbon dioxide raw material liquid storage tank 1 connected to a carbon dioxide inlet 9 of a dry ice maker 2, and a dry ice outlet of the dry ice maker 2 connected to a dry ice incubator 10 , it is characterized in that: the carbon dioxide gas phase outlet of the dry ice maker 2 is connected to the carbon dioxide inlet 9 of the dry ice maker 2 through the tubes of the carbon dioxide booster compressor 3, the high-efficiency degreaser 4, and the evaporator 5 in sequence; screw refrigeration The outlet of the compressor 6 passes through the tube side of the condenser 7, the liquid accumulator 8, the tee 19, the shell side of the economizer 17, the shell side of the evaporator 5, and is connected with the inlet of the screw refrigeration compressor 6; the first three The third end of the channel 19 is connected to the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com